HYDROCAL 1005 Manual for Installation and Operation Page 8/111

2.3 Preparation for installation

Before installation, a visual inspection of the unit must be carried out. Remove the protection cover

and check visually the components. All cables and tubes must be connected.

2.3.1 Power supply for the unit

The HYDROCAL1005 unit requires an auxiliary power supply of 110 / 230V close to the unit. The

power needed is max. 350 VA.

2.3.2 Requested tools:

Long Allen key, size 4 for aeration screw

Bucket, oil absorber, cleaning rag

Teflon-band

Drill / screw driver

Digital multimeter

Tin spanner M55 or adjustable tin spanner of 1 ½“ for valve and fittings

To seal the thread of the measuring head, either Teflon band (minimum 4 to 5 layers must be ap-

plied) or an O-Ring must be used.

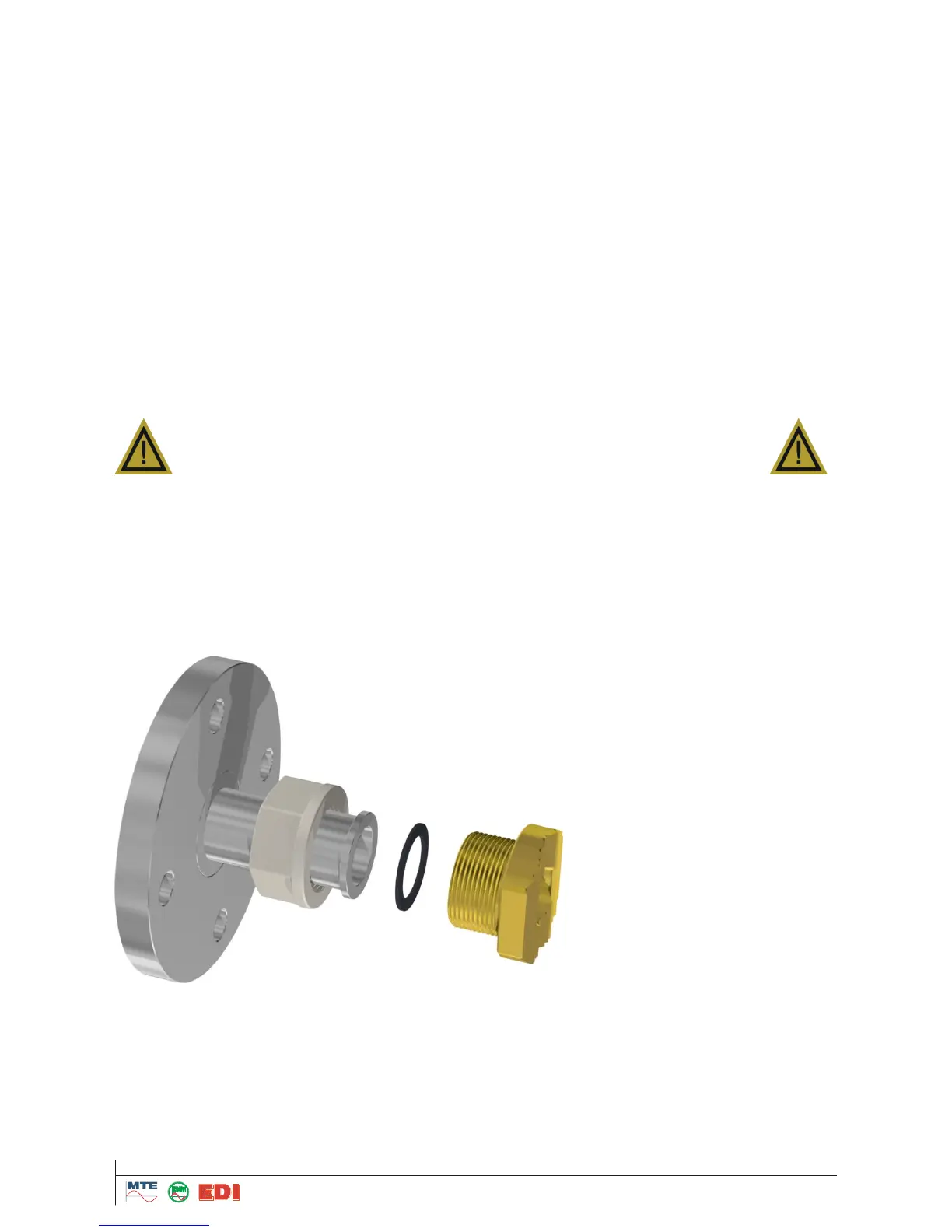

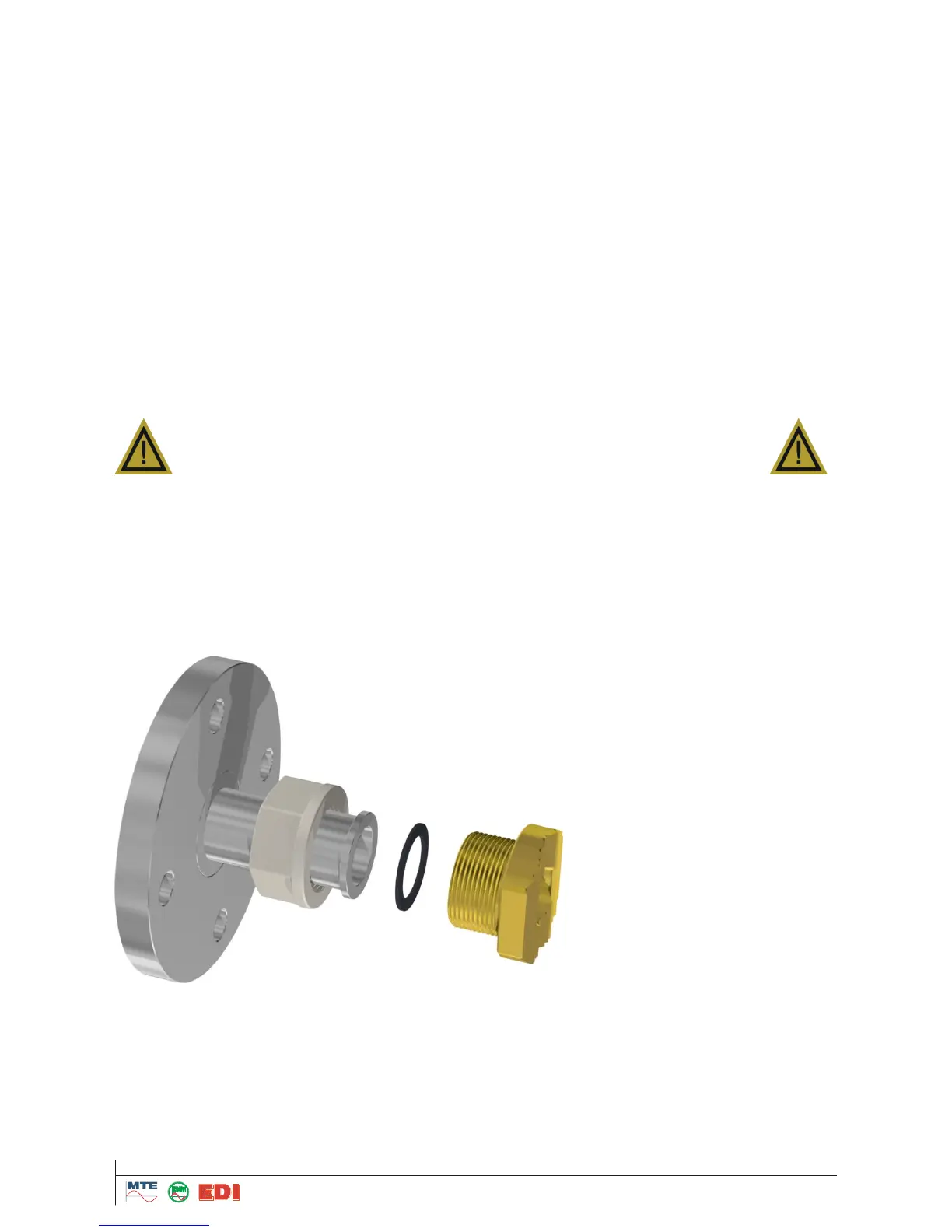

2.4 Installation of the HYDROCAL1005 unit

Please mount the HYDROCAL1005 unit on a valve with full opening (full bore valve) or a ball valve

with an internal thread of 1½” (DIN ISO 228: G 1½) . The HYDROCAL unit has a 1½’’ thread (Di-

mensional drawings, see. chapter 8). As an option a valve with NPT 1½ standard can also be used.

A good oil flux should exist on the mounting location. If necessary, use a reduction piece (adapter).

It is recommended to mount the HYDROCAL 1005 unit to valve with a union- or sleeve nut. In this

case the device has not to be turned to fix during the installation. An O-ring should be used as seal-

ing.

In case there exist strong vibrations on the mounting valve, the valve should be relieved by a sup-

port.

Then mount the unit according to the following steps:

Loading...

Loading...