Control System 24Service Manual – SC500

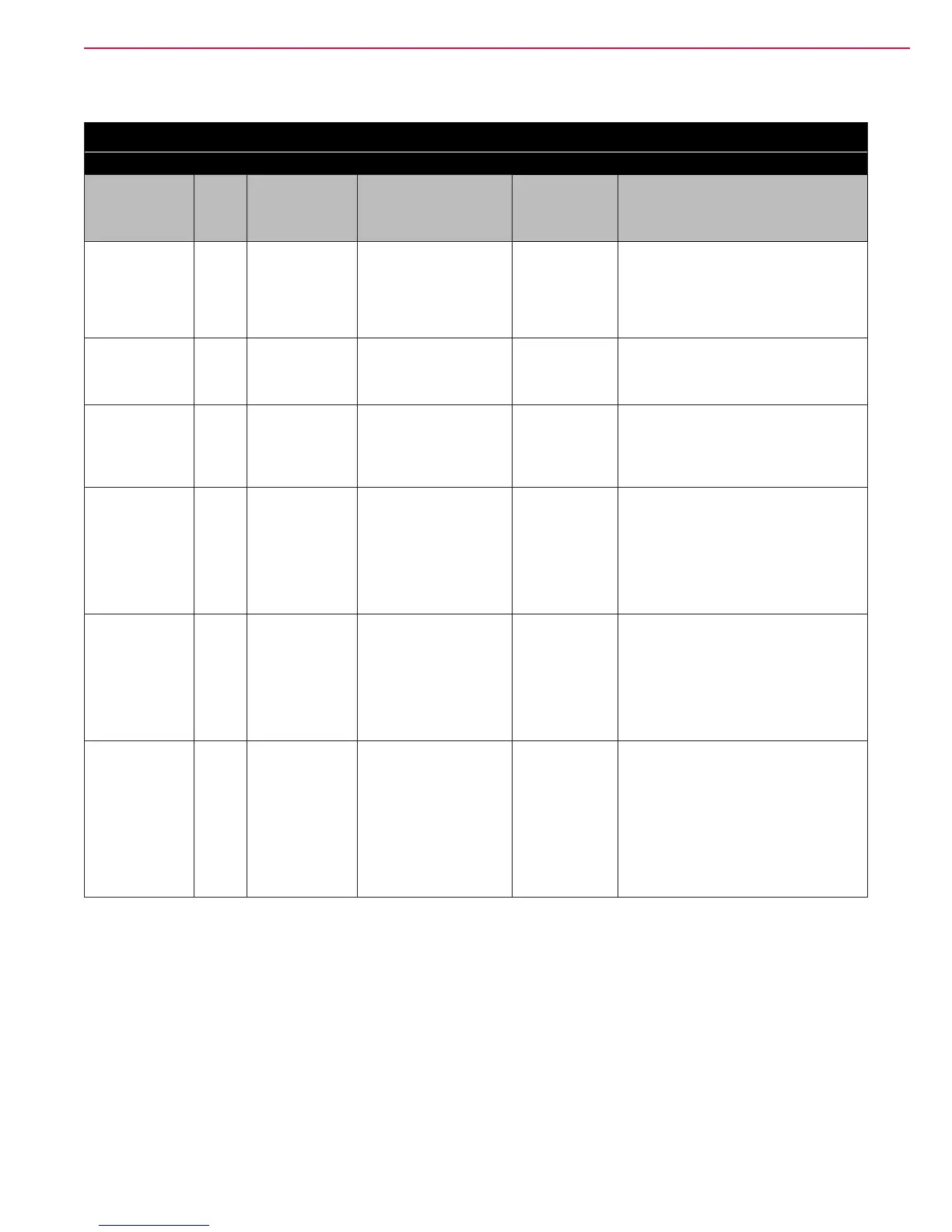

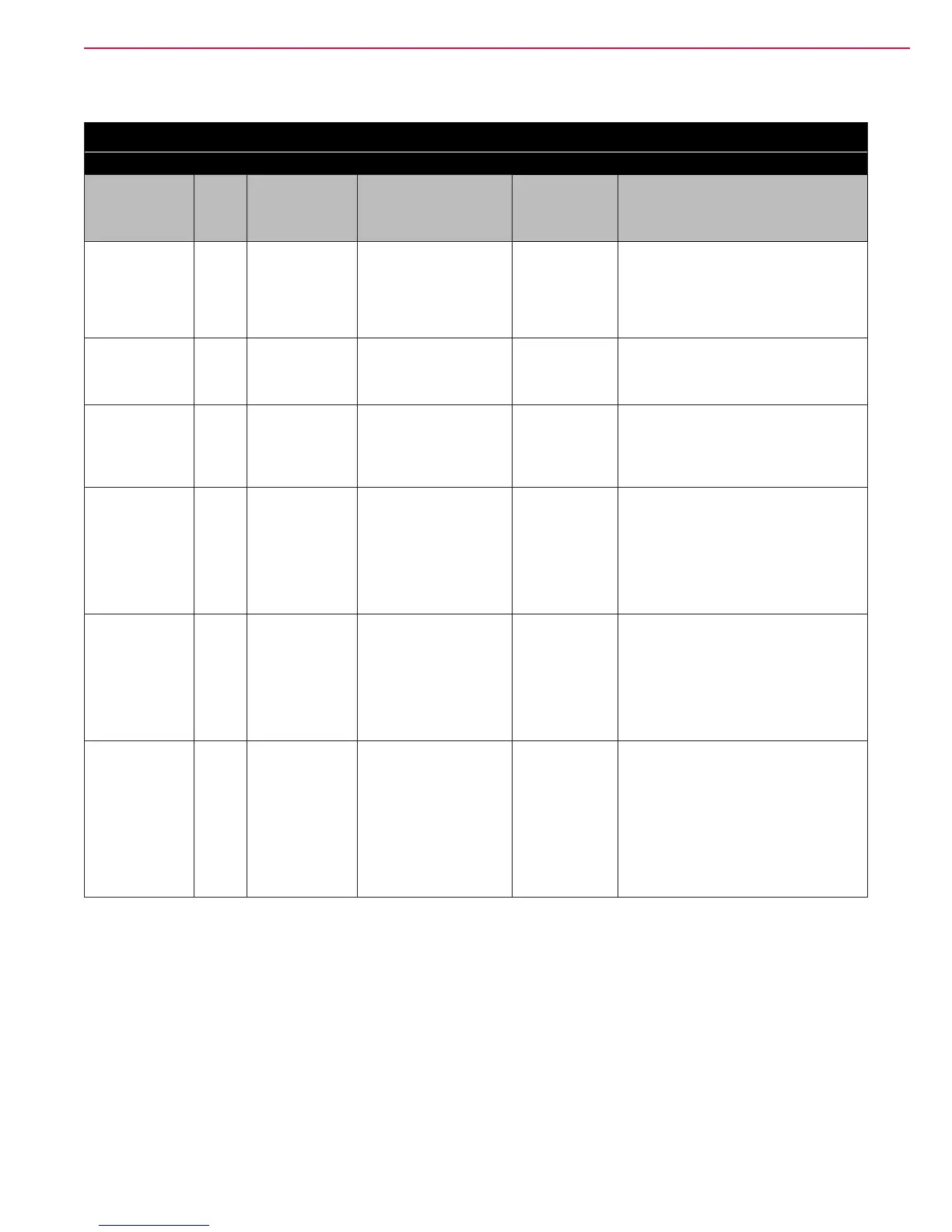

Function Board (EB1) Alarm Codes (Continues)

Drive system alarms

Alarm on Function Board - FLASHING YELLOW LED

Alarm code

--------------------------

Description

No.

ashes

on

board

Meaning Condition

Effect

Service Suggestions

T2

-----------------------

DRIVE MOTOR

OVERLOAD

2 Amperometric

protection

intervention.

Drive motor current

draw greater than the

parameter (see page 29 -

30) “INOM” for more than

the parameter (see page

29 - 30) “TMAX”.

Drive blocked. Check the current draw of the drive motor

(this should be around 6-8amps without

load and remain below 10-12amps during

operation).

T3

-----------------------

RELEASE THE

PADDLE !

3 Paddle not in rest

position when

board is turned

on.

Voltage on J1.2 of board

EB2 out of range 1.29V

- 1.49V with respect to

- BAT.

Drive blocked. Check that the paddle moves correctly,

lubricating if necessary; check the linkage

and potentiometer.

T4

-----------------------

PADDLE INPUT

FAILURE

4 Incorrect voltage

measured at

the paddle

potentiometer

input.

Voltage on J1.2 of board

EB2 above 3V.

Drive blocked. 1. Check the connection of the

potentiometer to the board.

2. Replace the potentiometer.

3. Replace the display board.

T5

-----------------------

HARDWARE

FAILURE

5 Drive system

power section

damage

MOSFET short circuit.

Drive blocked. 1. Check that the cables of the gear

motor are not short circuited (try

disconnecting the connectors from

contacts M1 and M2) and try starting

the machine and pressing the pedal

again

2. If the alarm persists, replace the board

T6

-----------------------

DRIVE MOTOR

FAILURE

6 Overcurrent

(motor D.C.)

Drive motor current

draw greater than 1.5

times the value of the

parameter (see page 29 -

30) “IMAX”.

Drive blocked. 1. Check that the gear motor cables are

not short circuited

2. Check that the motor of the gear

motor unit is not short circuited (the

impedance of the motor should be

around 0.6 – 0.8 Ohm)

3. If necessary, replace the gear motor

unit motor

T7

-----------------------

OVERHEATING

7 Drive motor drive

section thermal

cut-out.

The heatsink on the

board has reached a

temperature of 194°F

(90°C).

Drive blocked. 1. Check the drive motor power draw

and that the openings of the electrical

compartment are not blocked.

2. If everything is within normal

parameters, this may simply have been

caused by extreme working conditions

such as: Ambient temperature over

86°F (>30°C), sloping working sections.

Simply leave the system to cool and

turn the machine back on.

All alarms of the drive system operate by cutting the power supply to the gear motor unit motor until the KEY input is reset

(with the exception of alarm T3 which is reset as soon as the input voltage of the paddle potentiometer returns within the val-

ues corresponding to “machine stopped”). In case of simultaneous errors, the one with greater priority is shown rst (priority

order is opposite to the number of ashes).

Loading...

Loading...