296

Pulse Outputs Section 5-3

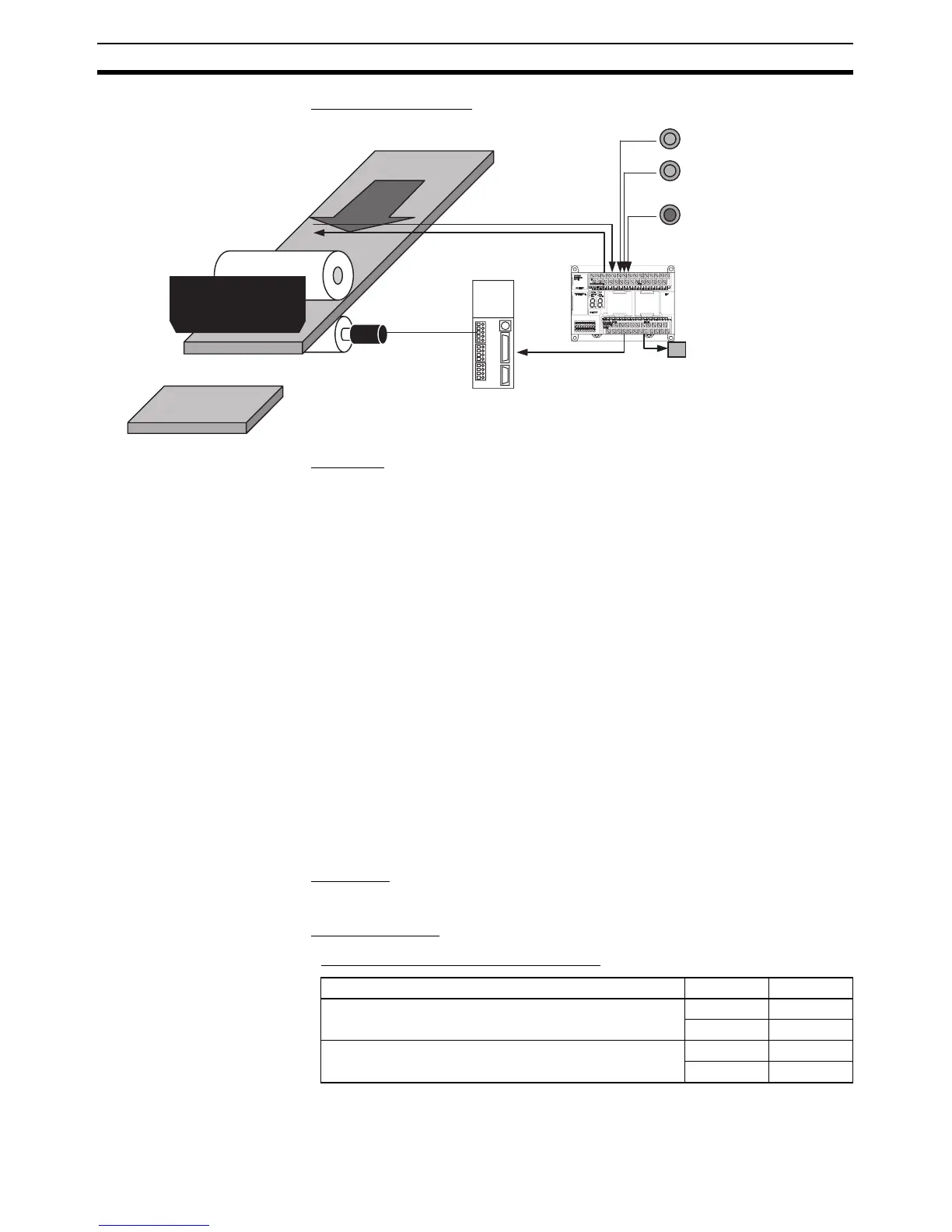

■ System Configuration

■ Operation

1,2,3... 1. The workpiece is set at the starting position using the Jogging Switch Input

(IN 1.04).

2. The workpiece is feed the specified distance (relative) using the Position-

ing Switch Input (IN 1.05).

3. When feeding has been completed, the cutter is activated using the Cutter

Start Output (OUT 101.00).

4. Feeding is started again when the Cutter Finished Input (IN 1.06) turns

ON.

5. The feeding/cutting operation is repeated for the number of times specified

for the counter (C0, 100 times).

6. When the operation has been completed, the Cutting Operation Finished

Output (OUT 101.01). is turned ON.

The feeding operation can be canceled and operation stopped at any point

using the Emergency Switch Input (IN 1.07).

Instructions Used SPED(885)

PLS2(887)

Preparation

■ PLC Setup

There are no settings that need to be made in the PLC Setup.

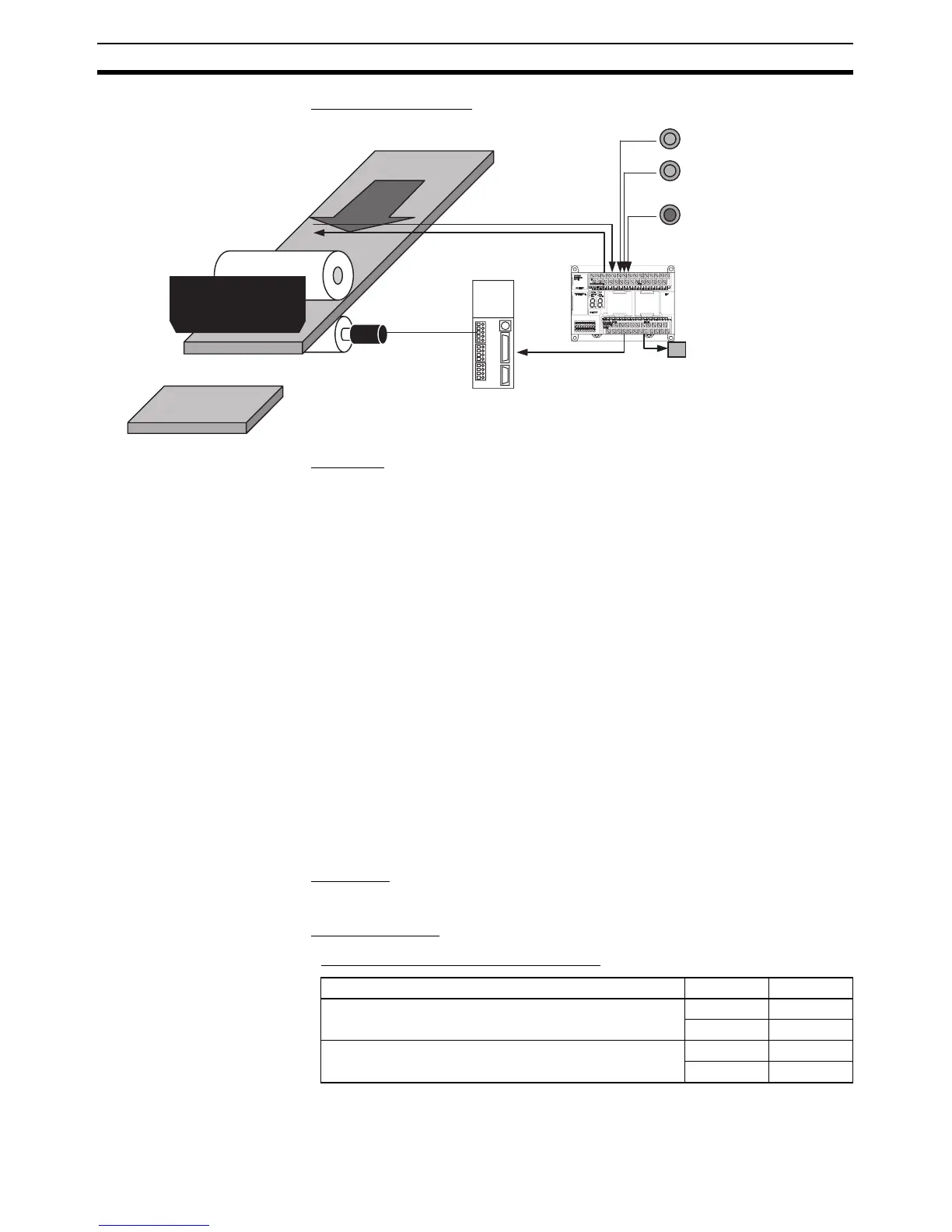

■ DM Area Settings

Speed Settings for Jogging (D0 to D3)

Jogging switch

IN 1.04

Positioning switch

IN 1.05

Emergency stop switch

IN 1.07

Cut operation finished

OUT 101.01

Pulse output (CW/CCW)

Cutter finished

IN 1.06

Cutter start

OUT 101.00

Built-in I/O other than pulse outputs are used.

Setting details Address Data

Target frequency: 1,000 Hz D0 #03E8

D1 #0000

Target frequency: 0 Hz D2 #0000

D3 #0000

Loading...

Loading...