2 Drag the following processing items from under Inspection and measurement support

items, or click the Insert button.

• Parallelize

• Parallelize Task

3

Program the processing items to execute in parallel between two Parallelize Task processing

items.

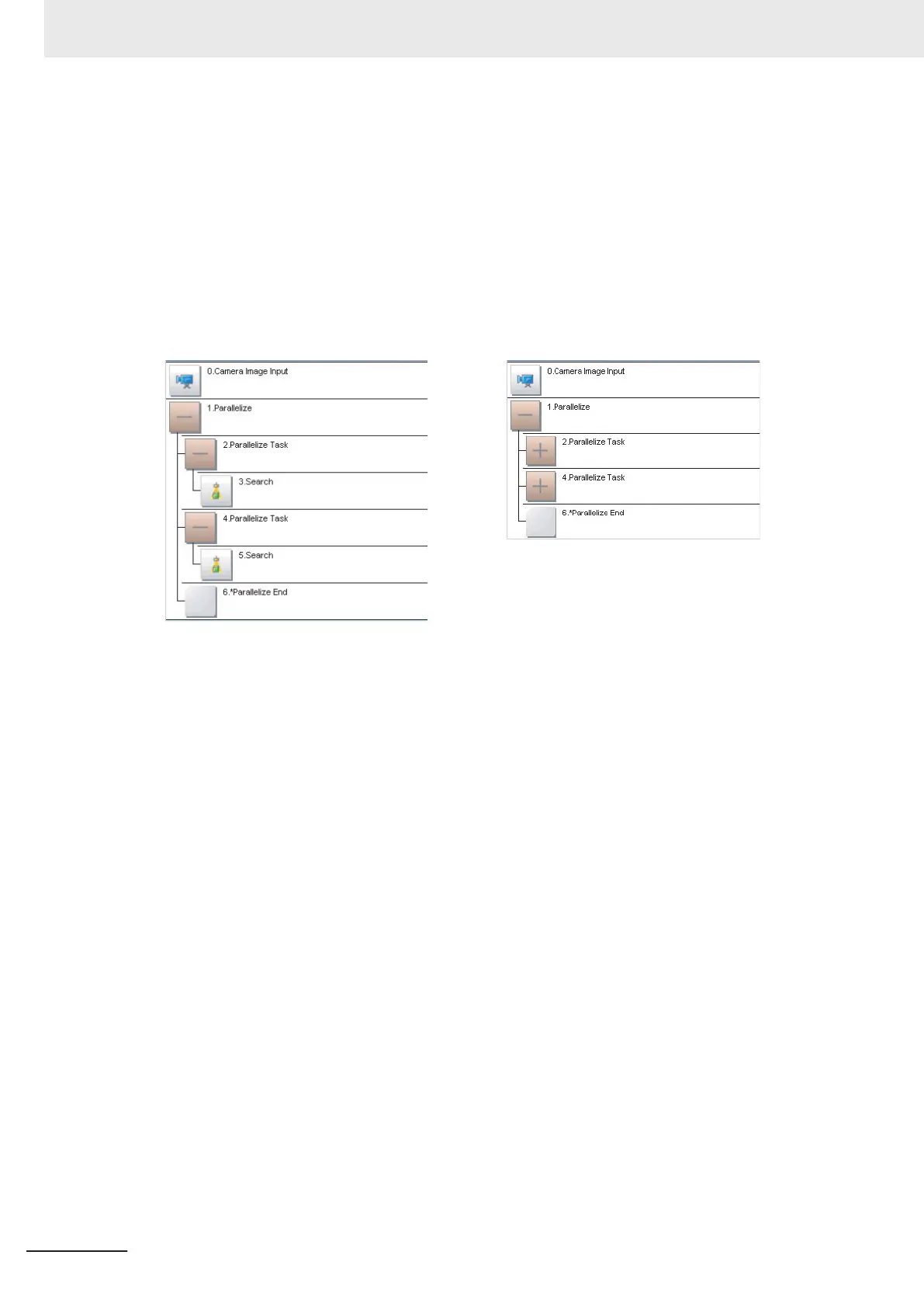

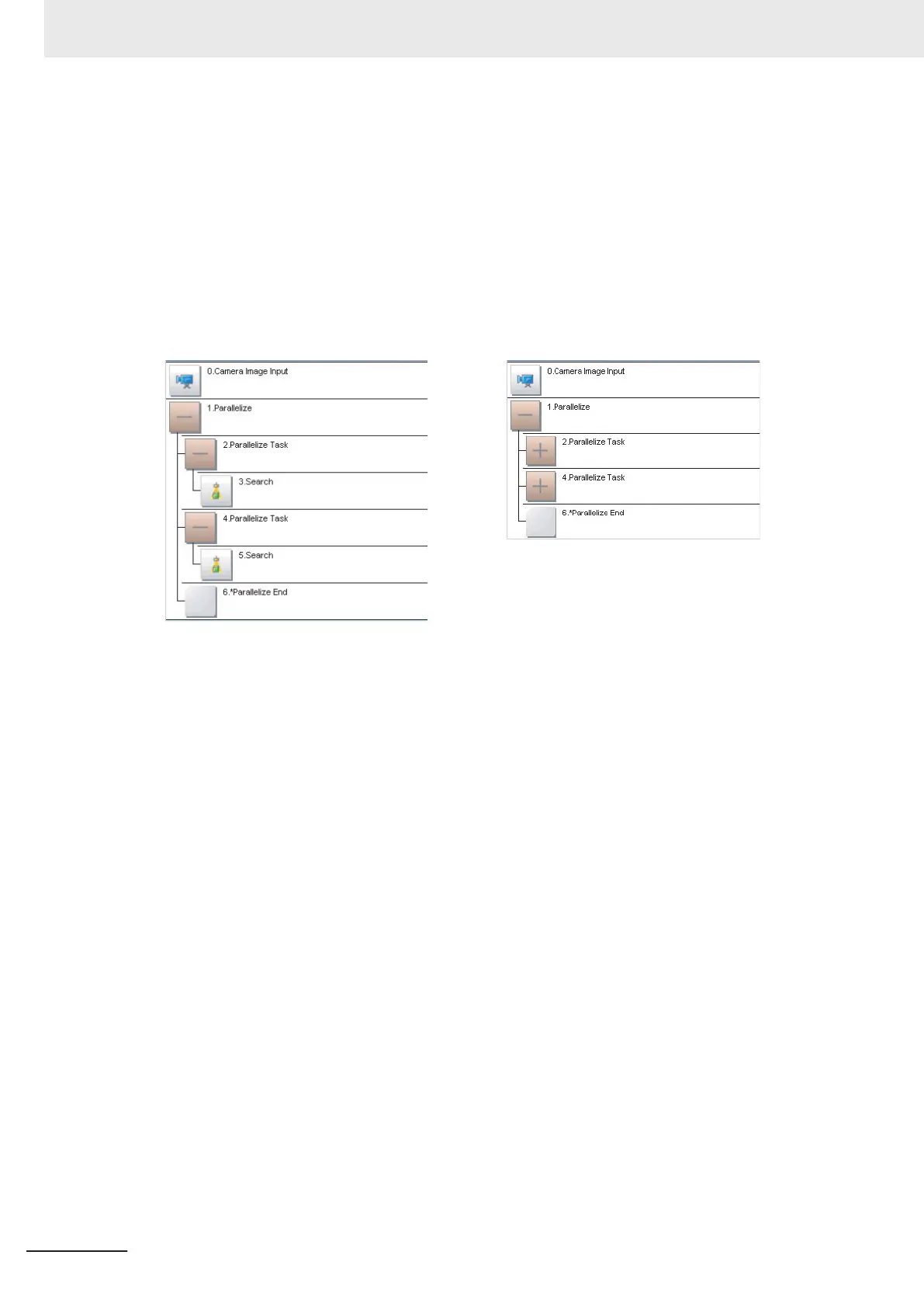

Example:

Fully Expanded Paralle Blocks Collapsed

The Parallelize processing item is the parent, and everything up to the Parallelize End processing

item is a child.

Additionally, the Parallelize Task processing item is the parent, and everything up to the step just

before the next Parallelize Task processing item or the Parallelize End processing item is a child.

There is no settings dialog box for Parallelize processing items.

The Parallelize End processing item is not displayed in the list of items. (It is registered as a set

with the Parallelize processing item).

l

Precautions on Flow Editing

• Editing operations on parallel blocks and task blocks, such as register, move, delete, copy, and

paste, and unit save and load operations, are performed on the parallel block as a group.

• You cannot delete a Parallelize End processing item by itself. It is deleted as a set with the

Parallelize processing item.

• You cannot paste or move items within the same parallel block.

• If a processing item in a parallel block is set to reference data in a processing unit that is inside

the block, and if that block is copied, the reference will be replaced with a reference to the unit in

the block at the copy destination.

References to a unit that is outside the parallel block will be retained.

• You cannot move, paste, or load a task block outside of its parallel block.

• When parallelizing processing units using variables, the processing units are not subject to auto-

matic parallelization. Therefore, rearrange the parallelization flow using parallelization processing

items. When rearrange the flow, consider the execution timing of the processing unit and the var-

iable input/output.

4 Setting the Controller

4 - 34

FH/FHV Series Vision System User’s Manual (Z365-E1)

Loading...

Loading...