1 Introduction to the Motion Control Function Module

1-14

NJ/NX-series CPU Unit Motion Control User’s Manual (W507)

*1 Unit version 2.1 or later is recommended for G5-series Cylinder-type Servo Drives. Unit version 1.1 or later is

recommended for G5-series Linear Motor Types.

*2 The recommended unit version is 1.1 or later.

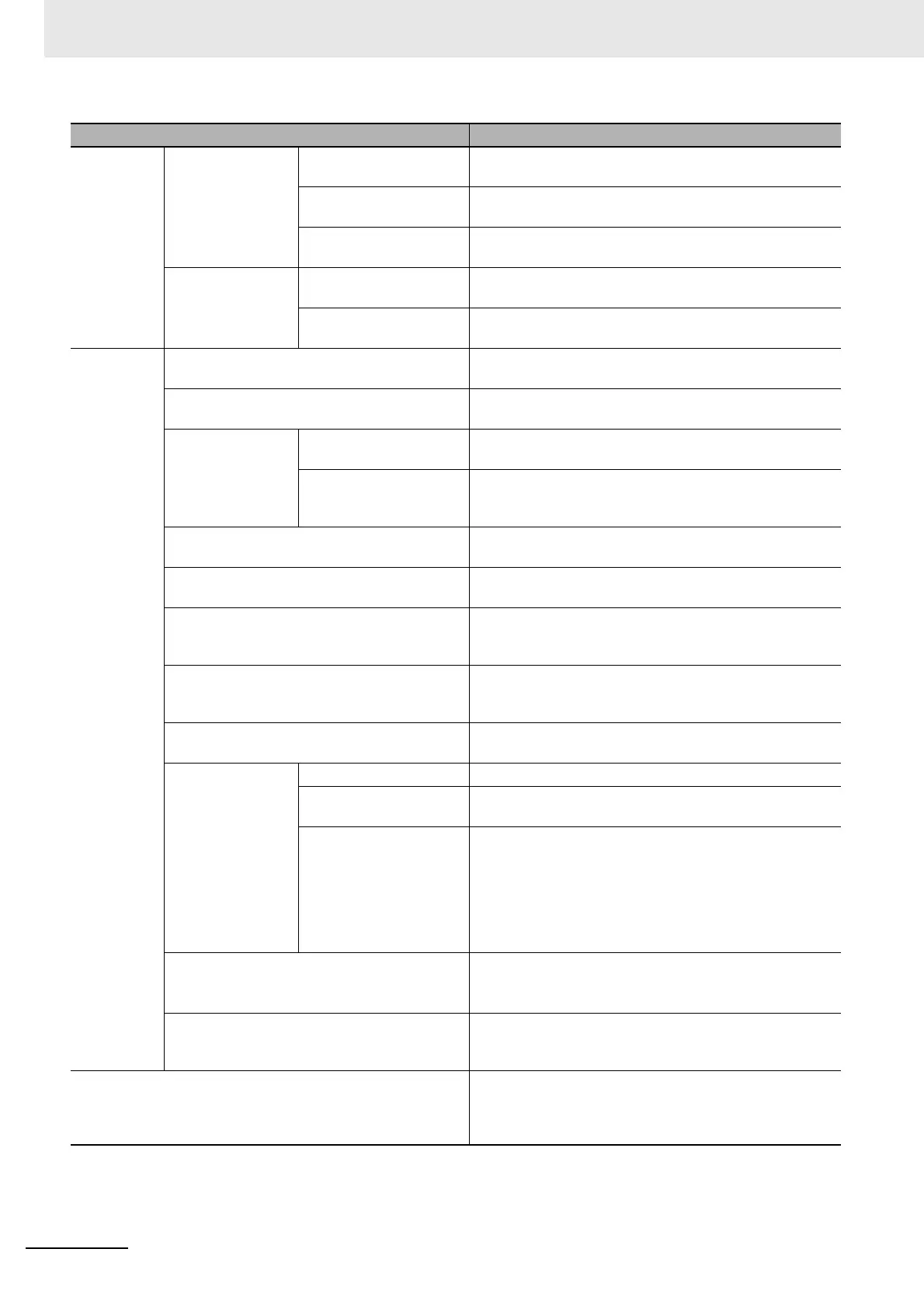

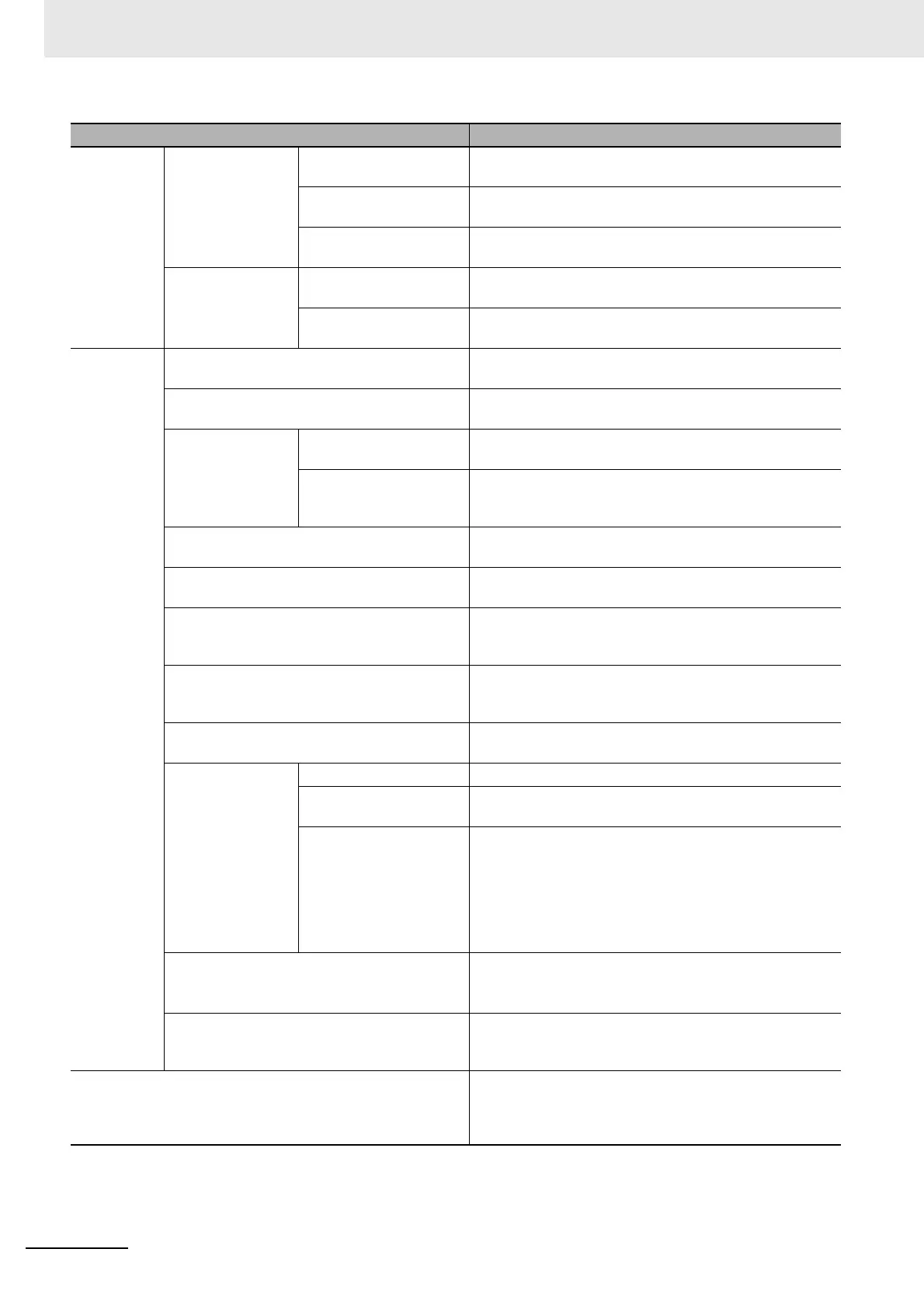

Common

items

Cams

*5

Setting cam table proper-

ties

The end point index of the cam table that is specified in

the input parameter is changed.

Saving cam tables The cam table that is specified with the input parameter is

saved in non-volatile memory in the CPU Unit.

Generating cam tables (*) The cam table that is specified with the input parameter is

generated from the cam property and cam node.

Parameters Writing MC settings Some of the axis parameters or axes group parameters

are overwritten temporarily.

Changing axis parame-

ters (*)

You can access and change the axis parameters from the

user program.

Auxiliary

functions

Count modes You can select either Linear Mode (finite length) or Rotary

Mode (infinite length).

Unit conversions You can set the display unit for each axis according to the

machine.

Acceleration/decel-

eration control

Automatic accelera-

tion/deceleration control

Jerk is set for the acceleration/deceleration curve for an

axis motion or axes group motion.

Changing the accelera-

tion and deceleration

rates

You can change the acceleration or deceleration rate even

during acceleration or deceleration.

In-position check You can set an in-position range and in-position check

time to confirm when positioning is completed.

Stop method You can set the stop method to the immediate stop input

signal or limit input signal.

Re-execution of motion control instructions You can change the input variables for a motion control

instruction during execution and execute the instruction

again to change the target values during operation.

Multi-execution of motion control instructions

(Buffer Mode)

You can specify when to start execution and how to con-

nect the velocities between operations when another

motion control instruction is executed during operation.

Continuous axes group motions (Transition

Mode)

You can specify the Transition Mode for multi-execution of

instructions for axes group operation.

Monitoring func-

tions

Software limits The movement range of an axis is monitored.

Following error The error between the command current value and the

actual current value is monitored for an axis.

Velocity, acceleration

rate, deceleration rate,

torque, interpolation

velocity, interpolation

acceleration rate, and

interpolation decelera-

tion rate

You can set and monitor warning values for each axis and

each axes group.

Absolute encoder support You can use an OMRON 1S-series Servomotor or G5-

series Servomotor with an Absolute Encoder to eliminate

the need to perform homing at startup.

*6

Input signal logic inversion (*) You can inverse the logic of immediate stop input signal,

positive limit input signal, negative limit input signal, or

home proximity input signal.

External interface signals The Servo Drive input signals listed on the right are used.

Home signal, home proximity signal, positive limit signal,

negative limit signal, immediate stop signal, and interrupt

input signal

Item Description

Loading...

Loading...