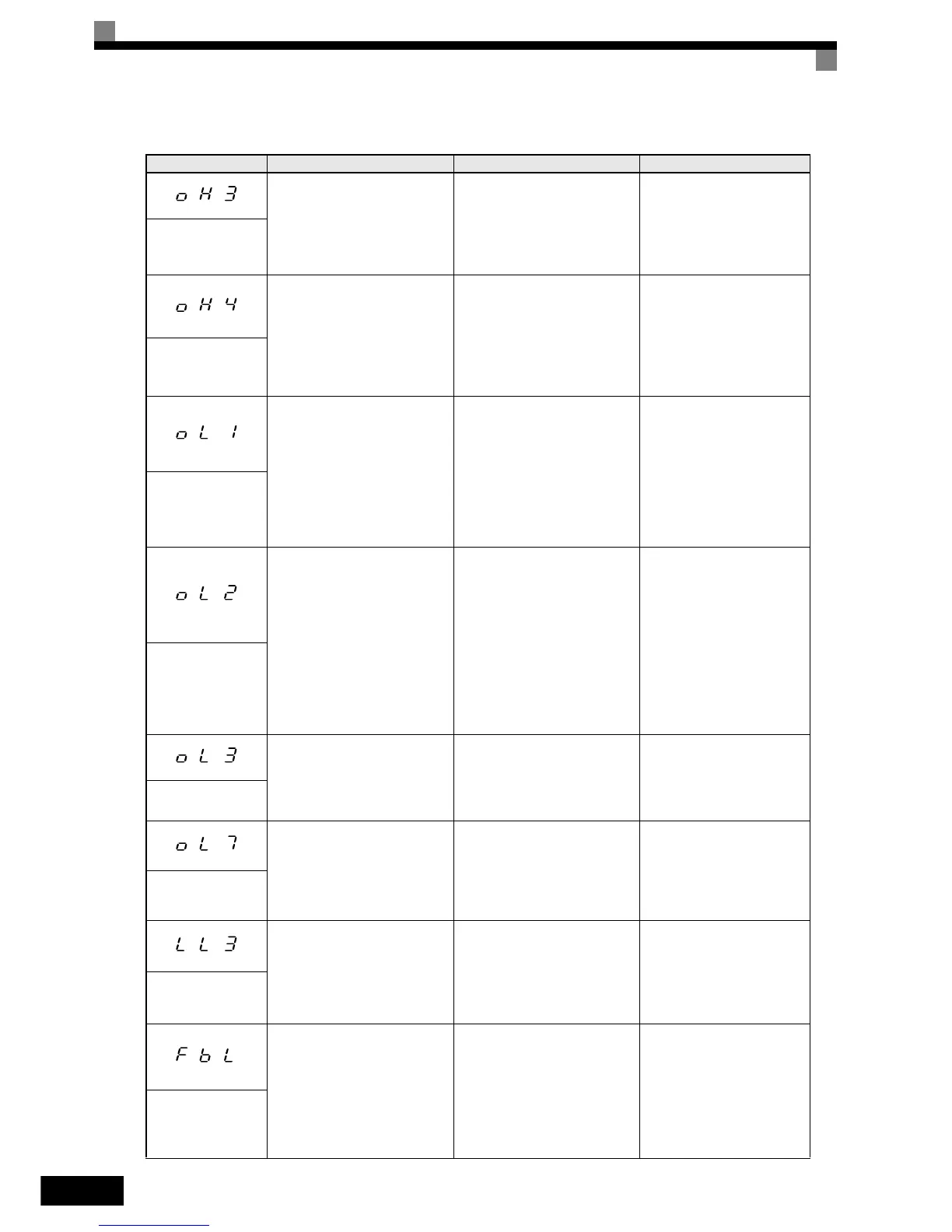

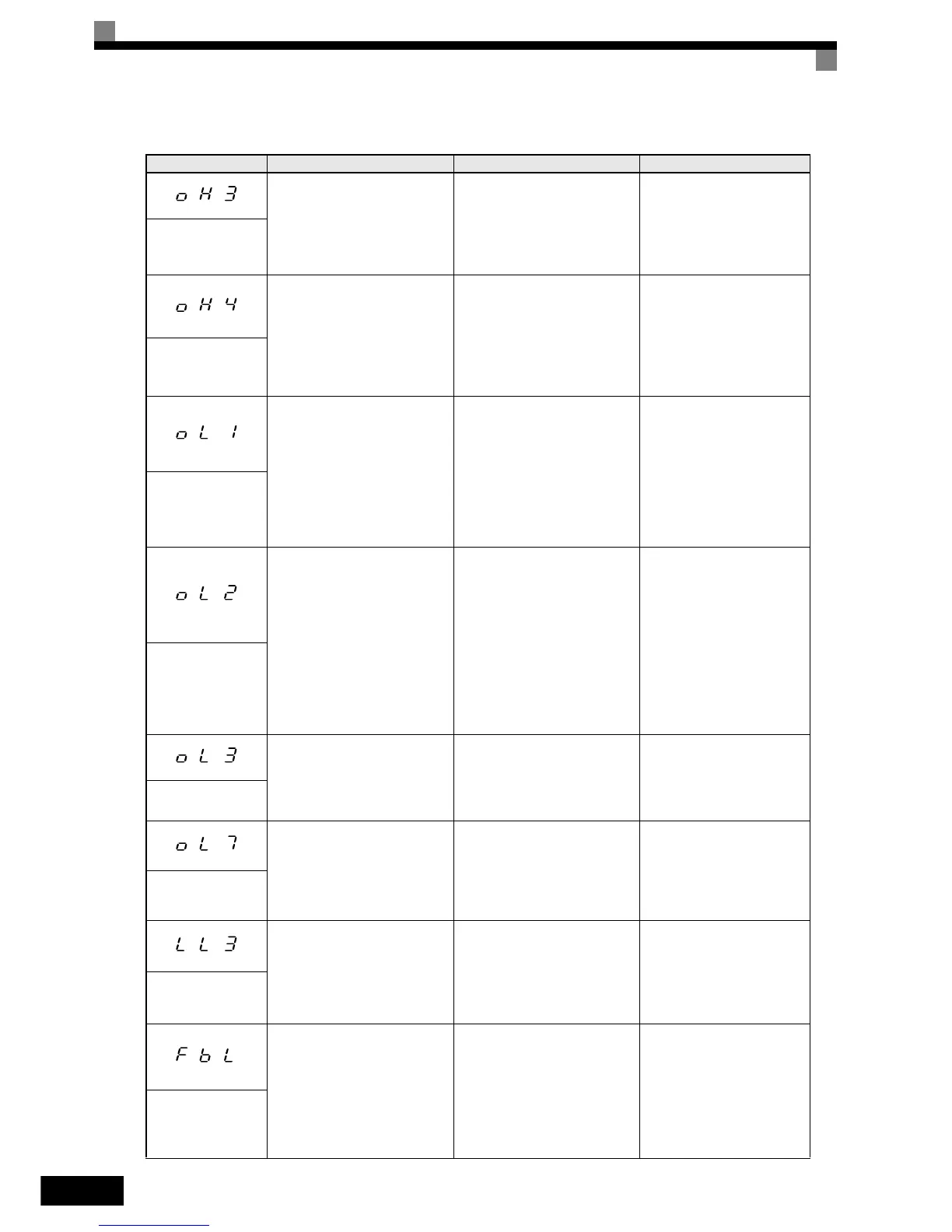

7-4

Motor Overheat

Detected when the level at A2,

programmed for motor tempera-

ture (thermistor input, H3-09=E),

exceeds 1.17 V for the time L1-

05 and L1-03 = 0 to 2.

Overheating of the motor has

been measured by the motor ther-

mistor.

• Check the cycle time and

the size of the load.

• Check the accel/decel times

(C1-).

• Check the V/f pattern

(E1-)

OH3

Motor Overheat 1

Motor Overheat

Detected when the level at A2,

programmed for motor tempera-

ture (thermistor input, H3-09=e),

exceeds 2.34 V for the time L1-

05.

Overheating of the motor has

been measured by the motor ther-

mistor.

• Check the cycle time and

the size of the load.

• Check the accel/decel times

(C1-).

• Check the V/f pattern

(E1-)

OH4

Motor Overheat 4

Motor Overload

Detected when L1-01 = 1 to 3 and

the Inverter’s output current

exceeded the motor overload

curve.

Refer to

page 6-33 for parameter

settings.

• The load is too large. The

acceleration time, deceleration

time and cycle time are too

short.

• The voltage settings of the V/f

pattern is incorrect for the

application

• The setting of the Motor Rated

Current (E2-01) is incorrect.

• Check the cycle time, the

size of the load and the

accel/decel time settings

(C1-).

• Check the setting of the V/f

pattern (E1-).

• Check the setting of Motor

Rated Current (E2-01)

OL1

Motor Overload

Inverter Overload

The internally calculated I²t value

(based on the Inverter rated cur-

rent) has exceeded its detection

level.

• The load is too large. The

acceleration time, deceleration

time and cycle time are too

short.

• The voltage settings of the V/f

pattern is incorrect for the

application

• The capacity of the Inverter is

too small

• Check the cycle time, the

size of the load and the

accel/decel time settings

(C1-).

• Check the setting of the V/f

pattern (E1-).

• Check the setting of Motor

Rated Current (E2-01)

• Check if the Inverter rated

current matches the motor

rated current.

OL2

Inv Overload

Overload Detection

Inverter’s output current

exceeded L6-02 for longer then

the time set in L6-03 and L6-

01=3 or 4.

Motor was overloaded

• Ensure the values in L6-02

and L6-03 are appropriate

• Check the application/

machine status to eliminate

fault.

OL3

Overtorque Det 1

High Slip Braking OL

The output frequency stayed con-

stant for longer than the time set

in n3-04 during High Slip Brak-

ing.

The inertia of the load is too

large.

• Make sure the load is an

inertial load.

• If possible, reduce the load

inertia

OL7

HSB OL

Loss of Load Detection

Inverter’s output current was

below L6-02 for longer then the

time set in L6-03 and

L6-01= 7 or 8.

Motor lost its load

• Make sure that the settings

in L6-02 and L6-03 are

appropriate.

• Check the mechanical sys-

tem (mechanical connection

of the load, e.g. belt).

LL3

Loss of Load Det

PI Feedback Lost

This fault occurs when PI feed-

back loss detection is pro-

grammed to fault (b5-12 = 2) and

the PI feedback fell below the PI

Feedback Loss Detection Level

(b5-13) for the PI Feedback Loss

Detection Time (b5-14)

PI feedback source (e.g. trans-

ducer, sensor, building automa-

tion signal) is not installed

correctly or is not working

• Check the PI feedback sig-

nal source for correct opera-

tion.

• Check the wiring of the PI

feedback signal.

FBL

Feedback Loss

Table 7.1 Fault Detection

Display Meaning Probable Causes Corrective Actions

Loading...

Loading...