Amount

Cups

* Area

Cup

[mm] = 14700

Payload [kg]

Vacuum [kPa]

It is often a good idea to use more vacuum cups than needed, to accommodate for vibrations,

leaks and other unexpected conditions. However, the more vacuum cups, the more air

leakage (air

flow) is expected and the more air is moved in a grip resulting in longer gripping

times.

When using porous materials, the vacuum that can be achieve by using the OnRobot suction

cups will depend on the material itself and will be between the range stated in the

specifications. Some of the most common non-porous materials are listed below:

•

Fabrics

•

Foam

•

Foam with open cells

•

Low density cardboard

•

Low density paper

•

Perforated materials

•

Untreated wood

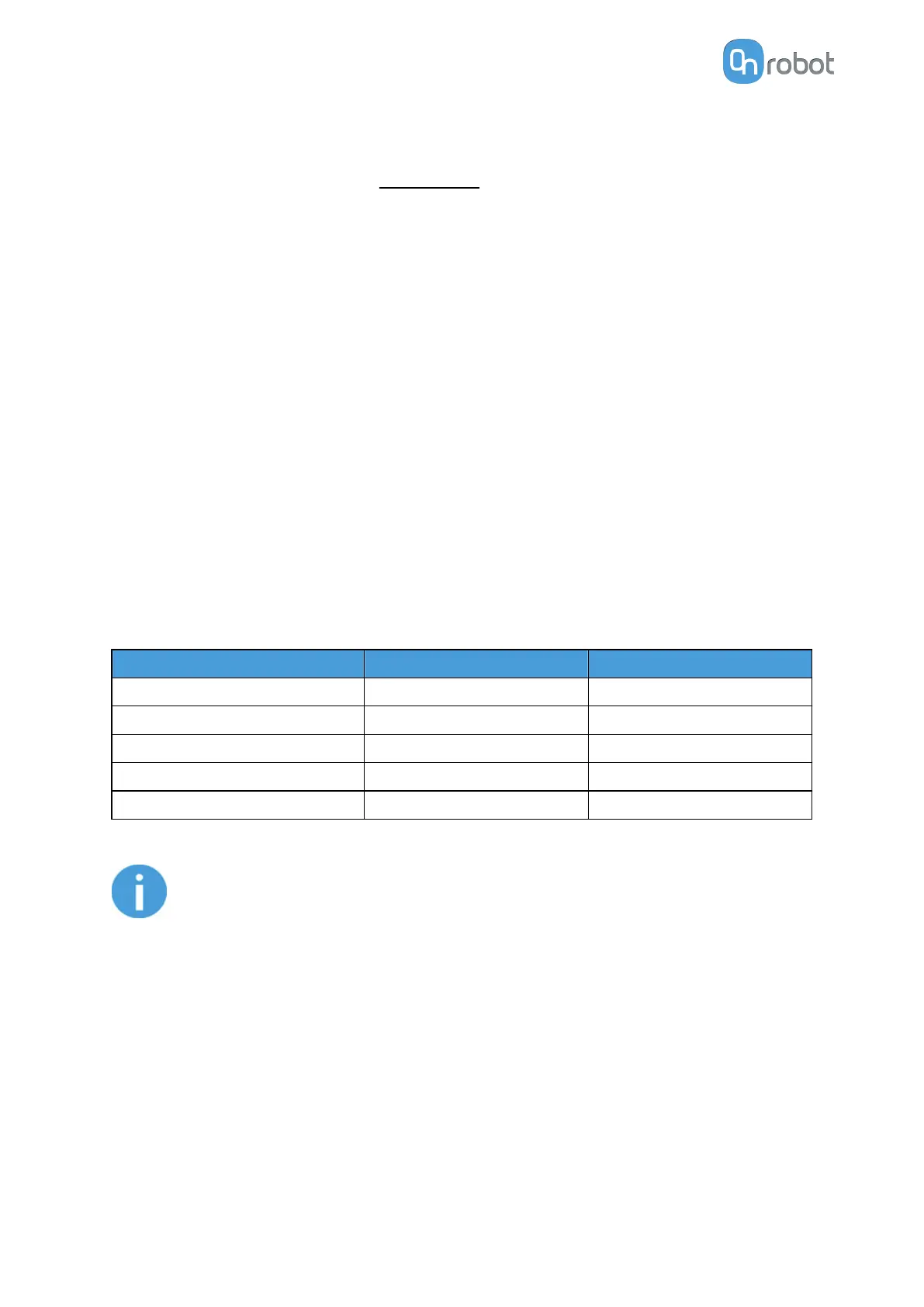

See the table below with general recommendations, in case other suction cups are needed

for

specific materials.

Workpiece surface

Vacuum cup shape Vacuum cup material

Hard and flat Normal or dual lip Silicone or NBR

Soft plastic or plastic bag Special plastic bag type Special plastic bag type

Hard but curved or uneven Thin dual lip Silicone or soft NBR

To be painted afterwards Any type NBR only

Varying heights 1.5 or more bevels Any type

NOTE:

It is recommended to consult a vacuum cup specialist to find the optimal

vacuum cup where the standard types are insucient.

Suction Cups for Foil and Bags Ø25

This suction cup improves the vacuum gripper’s ability to pick and place workpieces with

surface of foil, thin paper, and plastic bags during irregular and angular arm movement.

HARDWARE SPECIFICATION

224

Loading...

Loading...