Unused holes can be blinded using a blind screw, and each fitting can be changed to a

dierent type to match the desired suction cup. The fittings and the blinding screws are

mounted or dismounted by screwing (2Nm tightening torque) or unscrewing them with the

provided 3 mm Allen key.

The thread size is the commonly used G1/8”; allowing for standard fittings, blinders and

extenders to be fitted directly to the VG grippers.

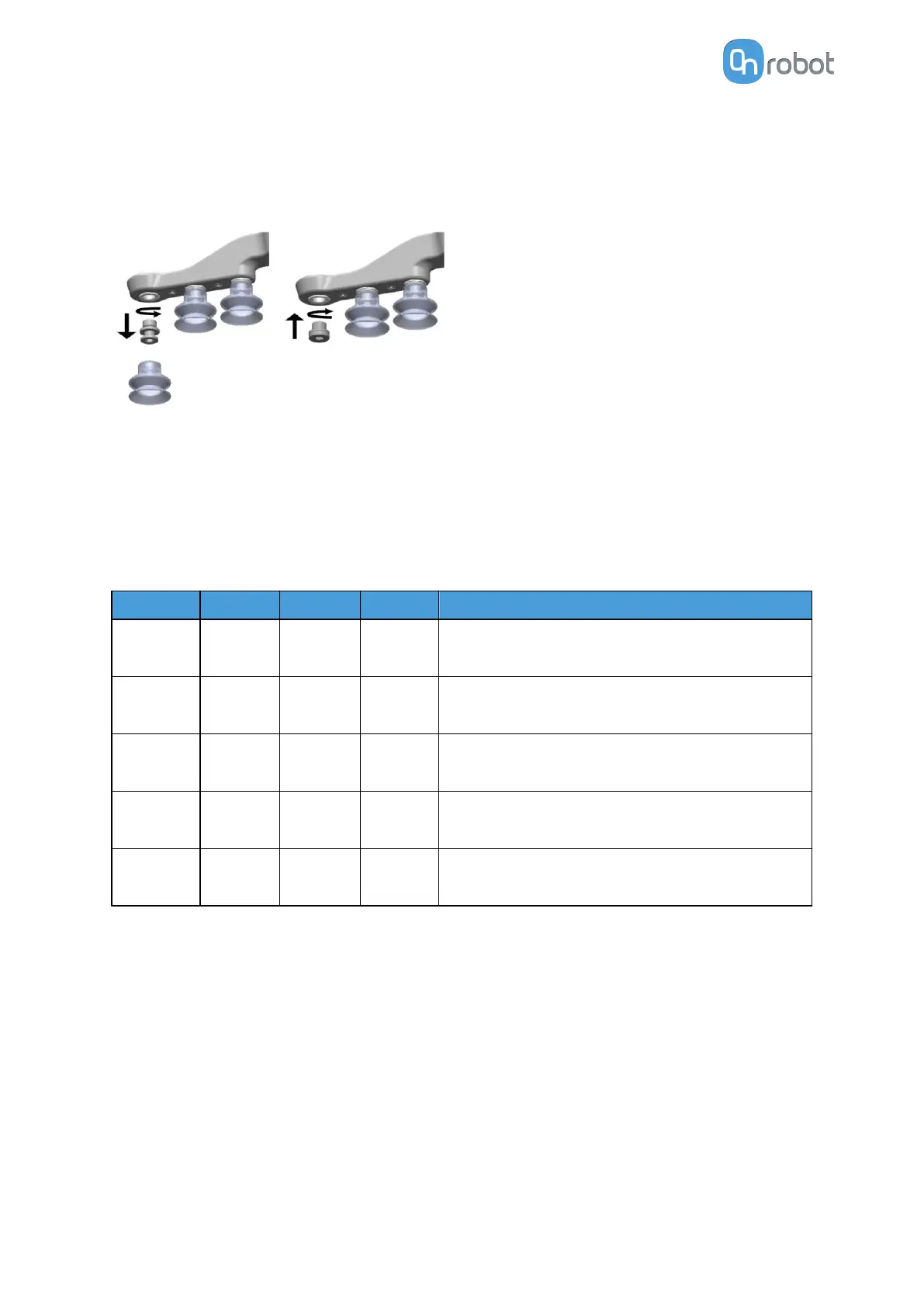

Vacuum

Vacuum is defined as the percentage of absolute vacuum achieved relative to atmospheric

pressure, i.e.:

% vacuum

Bar kPa inHg Typically used for

0% 0.00rel.

1.01 abs.

0.00rel.

101.3 abs.

0.0rel.

29.9 abs.

No vacuum / No lifting capacity

20% 0.20rel.

0.81 abs.

20.3rel.

81.1 abs.

6.0rel.

23.9 abs.

Cardboard and thin plastics

40% 0.41rel.

0.61 abs.

40.5rel.

60.8 abs.

12.0rel.

18.0 abs.

Light workpieces and long suction cup life span

60% 0.61rel.

0.41 abs.

60.8rel.

40.5 abs.

18.0rel.

12.0 abs.

Heavy workpieces and strongly secured grips

80% 0.81rel.

0.20 abs.

81.1rel.

20.3 abs.

23.9rel.

6.0 abs.

Max. vacuum. Not recommended

The vacuum in kPa setting is the target vacuum. The pump will run at full speed until the

target vacuum is achieved, and then run at a lower speed necessary to maintain the target

vacuum.

The pressure in the atmosphere varies with weather, temperature and altitude. The VG

grippers automatically compensate for altitudes up to 2km, where the pressure is about 80%

of sea level.

Air Flow

Air

flow is the amount of air that must be pumped to maintain the target vacuum. A completely

tight system will not have any air flow, whereas real life applications have some smaller air

leakages from two dierent sources:

HARDWARE SPECIFICATION

226

Loading...

Loading...