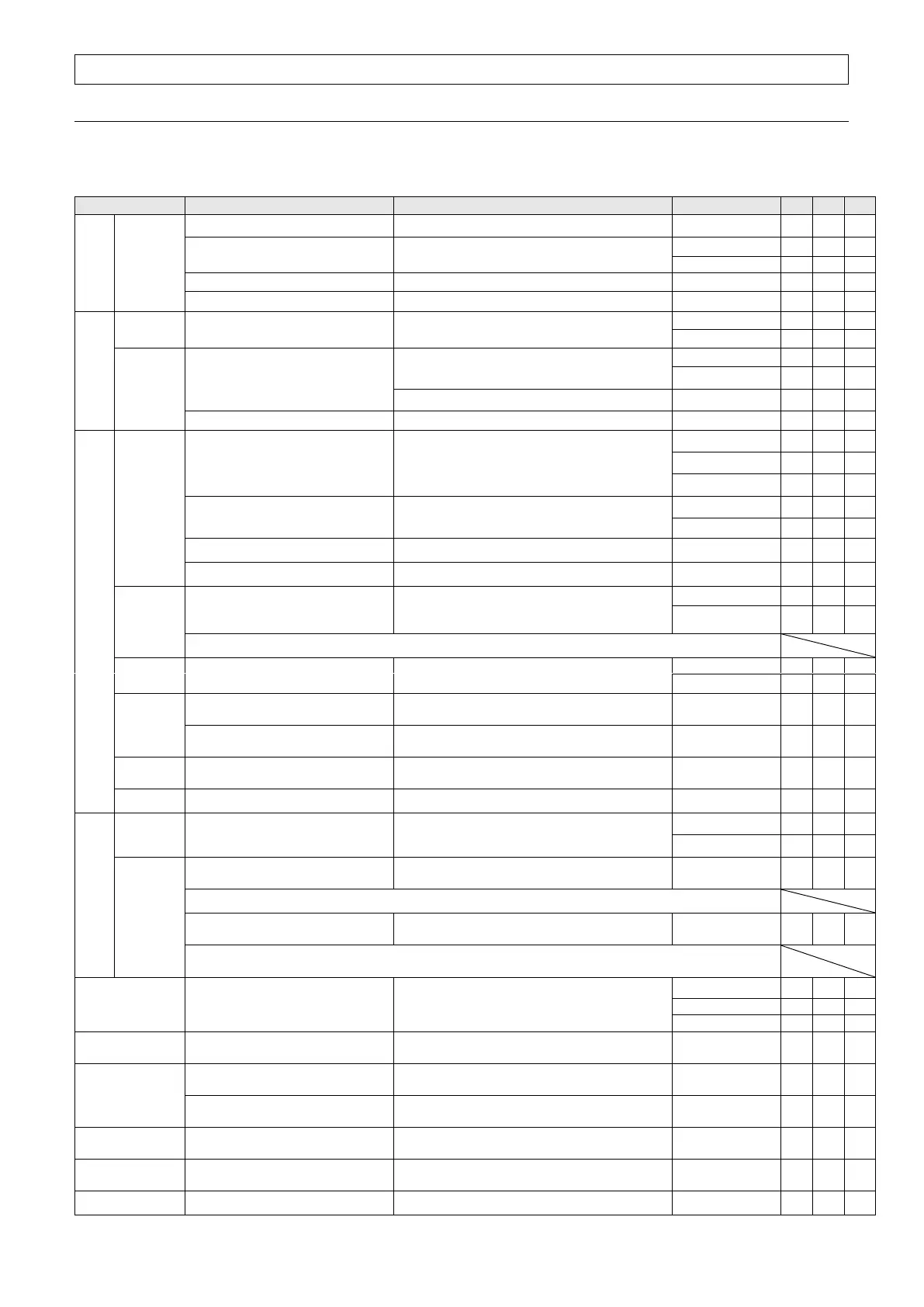

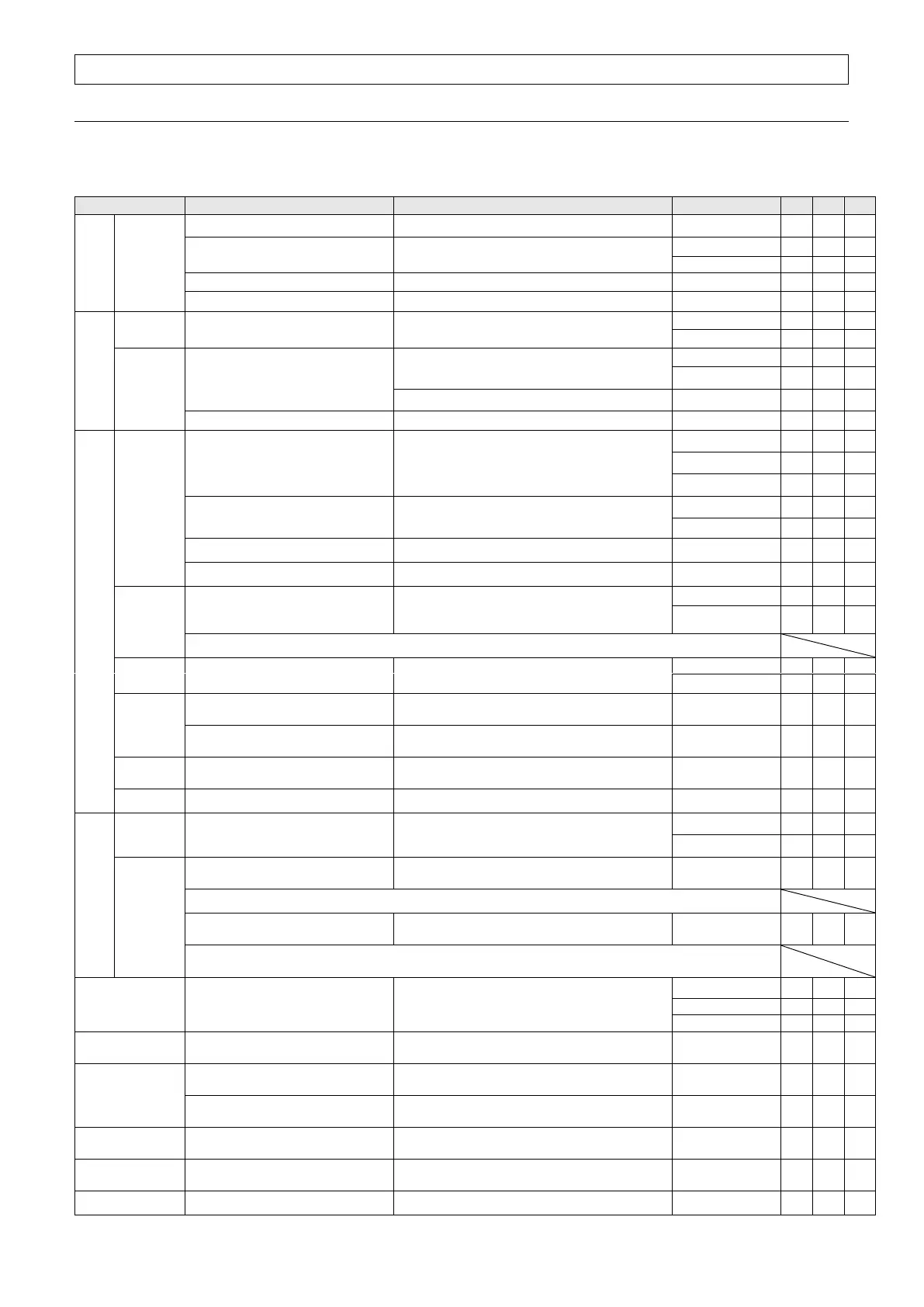

7. 点検表

- 58 -

7. check list

7.1 Periodic inspection table

★Failure to perform inspection or maintenance may result in an accident or malfunction. Please perform inspection

by referring to this "Periodic inspection table" so that normal functions can be exerted and always in a safe state.

★Make annual inspection a year, monthly inspection a month, and start-up inspection every time before work.

Parking brake effectiveness

Is there no drag, or is it not lose?

Is there deformation or backlash?

No bends, cracks or corrosion、

Is the flapper rubber attached properly?

Blade & Stay (Knife)

and installation

Is there any warp or wear?

Is the bolt / nut loose, worn, or dropped?

Braking effect (Stop within 5 seconds)

Acceleration, exhaust, choke

operating status.

Acceleration is smooth, exhaust color and

odor are normal, and choke operation is

smooth?

Setting is loose or not corroded

Is the state of charge of the battery good?

Is the engine mounted loose and cracked?

Is it dirty, clogged, torn or scratched?

Check for quantity, quality, leakage, and

foreign matter. Is replacement time

appropriate?

【Engine oil: 5H for the first time, change every 50H thereafter, and every 100H filter】

Check for fuel leaks, deterioration,

deformation, or clogging

Is there any crack in the insulator or

carbon accumulation?

High-voltage cord, plug cap

Is there deterioration, cracks, or cracks in

the cap?

Is there any accumulation of grass debris

in the housing?

Check for tension, cracks, damage, and

significant dirt.

Quantity, quality, oil leakage, foreign

matter (water, air) mixing

【Mission oil: 20H for the first time. After that, exchange at 100H】

HST Oil(Applicable products)

Quantity, quality, oil leakage, foreign

matter (water, air) mixing

【HST oil (equivalent to VG46): First time "Refer to each instruction manual".

After that, 200H or exchange once a year. (Replace the HST oil filter at the same time)】

Movable state of levers, wires,

etc.

Is the operation smooth?

Check for sticking or rust.

Operation, N position is proper, lose or

loose

Is the air pressure proper and is there no

damage or uneven wear?

Check the bolts and nuts for looseness and

dropped out.

Check the bolts and nuts for looseness and

dropped out.

Hour meter (Applicable

products)

Is the display time applicable and is the

operating status appropriate?

Warning label and nameplate

Adhesion is proper (peeling), damage, dirt

Loading...

Loading...