CO check

Preparing the vehicle

- Remove the 2 bottom sides as explained in the

Body chapter.

- Remove the 3 fastening screws of the filter box.

- Remove the filter box to access the 6 screws M6

closing the crankcase and the heat guard plate at-

tachments.

- Remove the plate to access the flow adjustment

screw on the carburettor.

- Remove the gas cap on the exhaust pipe.

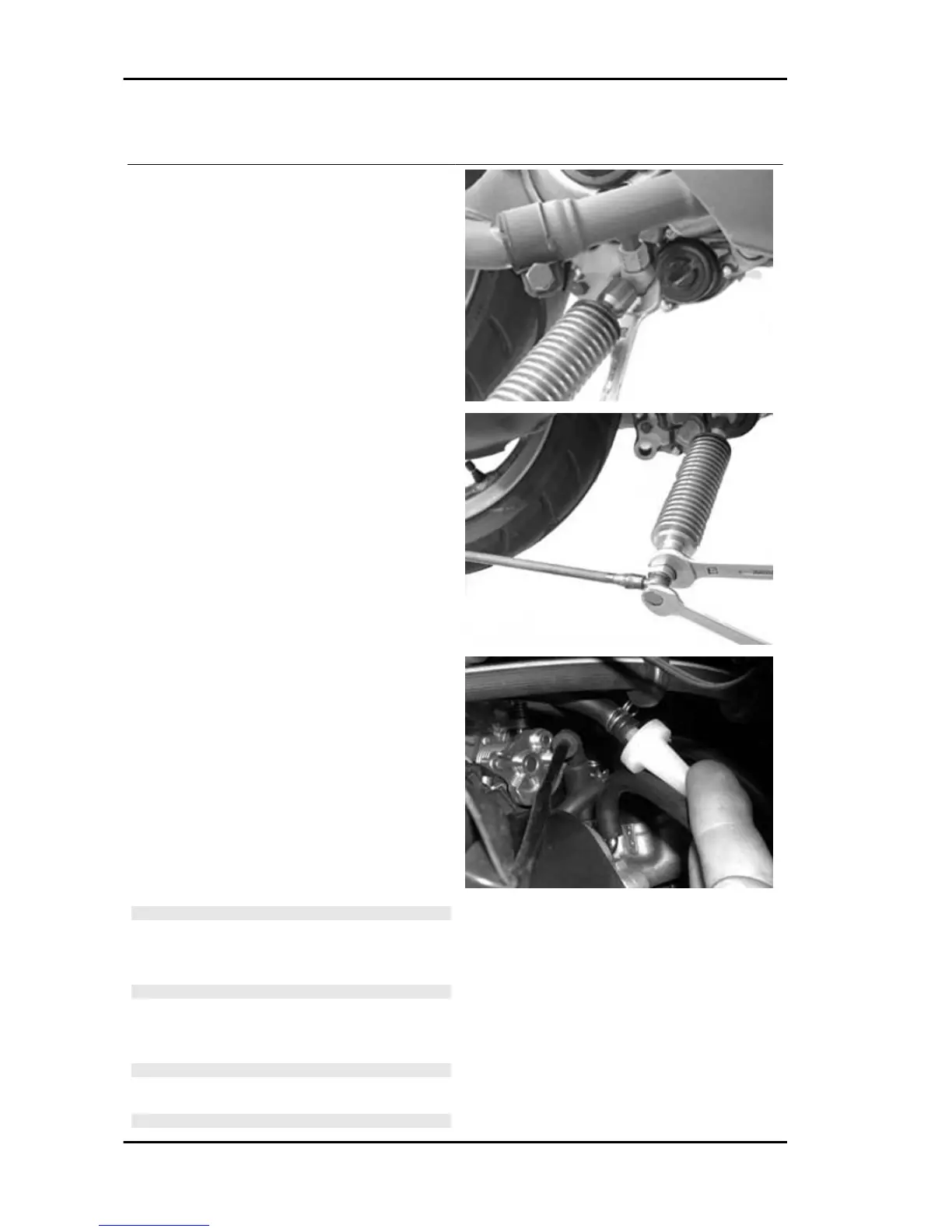

- Using the original washer, install the exhaust gas

collection Kit union.

- Suitably orientate the components (Figure 2).

- Close the gas outlet terminal of the tool. - Start

the engine and let it warn until the electric fan

starts.

- Stop the engine.

- Disconnect the vacuum feeding pipe from the

SAS control valve.

- Insert a conical plug into the vacuum feeding

pump.

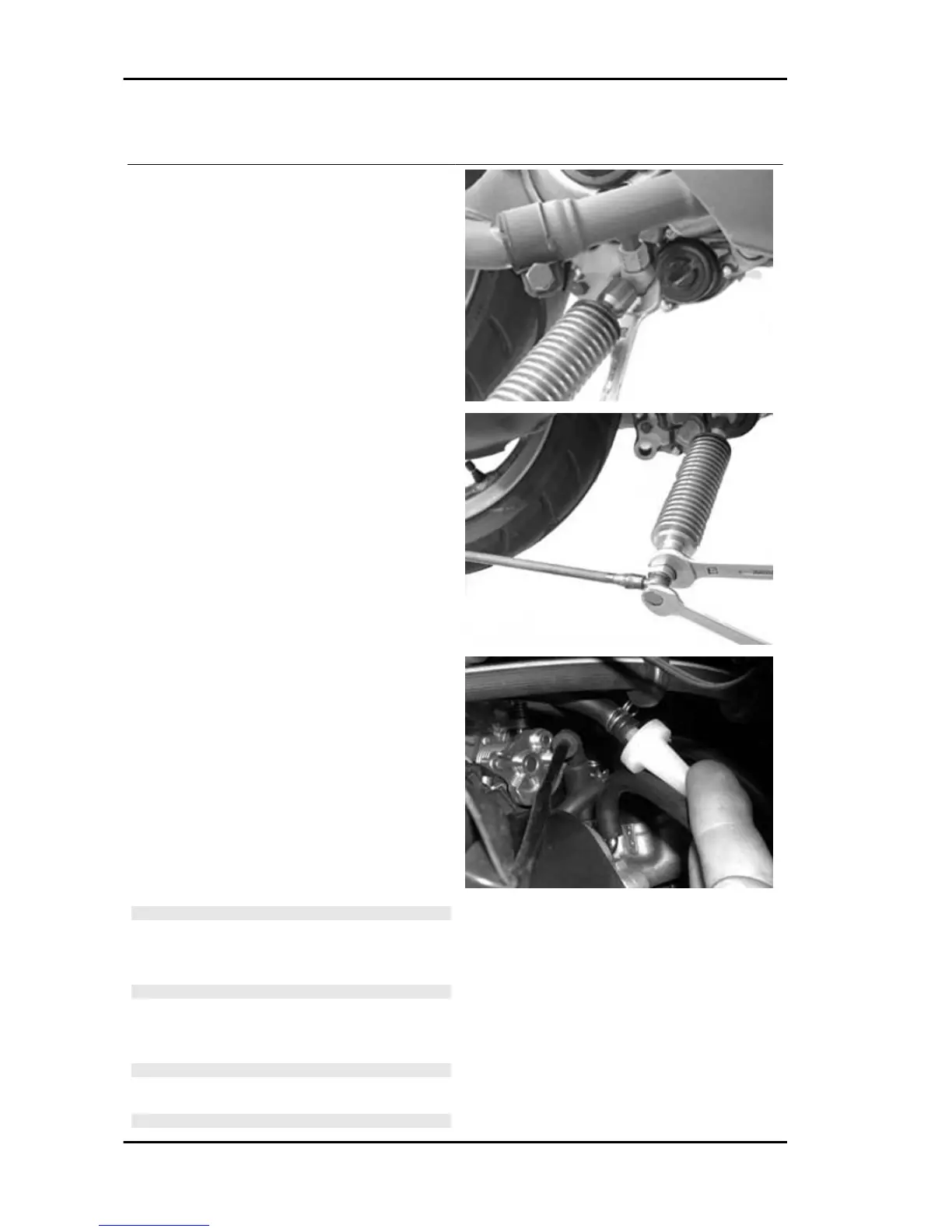

- Connect the MITIVAC vacuum pump to the SAS

control valve using a suitable pipe having the same

size as the original fitted on the vehicle.

- Start the vacuum up to -0.6 -0.8 Bar so as to close

the valve and cut off the SAS system.

- Remove the exhaust gas collection Kit closing

cap and connect the analyser properly pre-heated.

N.B.

IN CASE OF 1000 PPM UNBURNED HYDROCARBONS

(HC) >, CHECK THE IGNITION SYSTEM, THE TIMING SYS-

TEM, THE VALVE CLEARANCE AND THE EXHAUST

VALVE TIGHTNESS.

N.B.

IN CASE OF UNSTABLE CO, CHECK THAT THE CARBU-

RETTOR IS CLEAN AND THAT THE FUEL SUPPLY SYS-

TEM AND THE DEPRESSION SEALS WORK ADEQUATE-

LY

N.B.

OTHERWISE, CHECK THE FUEL LEVEL ADJUSTMENT IN

THE TANK AND THE FUEL CIRCUIT.

N.B.

Maintenance MSS X9 Evolution 250

MAIN - 44

Loading...

Loading...