Sequence and times must be strictly observed or

it will be necessary to repeat the procedure from

the start.

Once the control unit has been programmed, the

control unit is inseparably matched with the MAS-

TER key transponder.

This matching allows programming further service

keys in case of loss, replacement, etc. Each new

time new data is programmed the previously stor-

ed one is deleted.

If a service key setting is lost, it is essential to

carefully check the efficiency of the high voltage

system:

Shielded cap resistance ~ 5000 Ω.

In any case it is advisable to use resistive spark

plugs.

Diagnostic codes

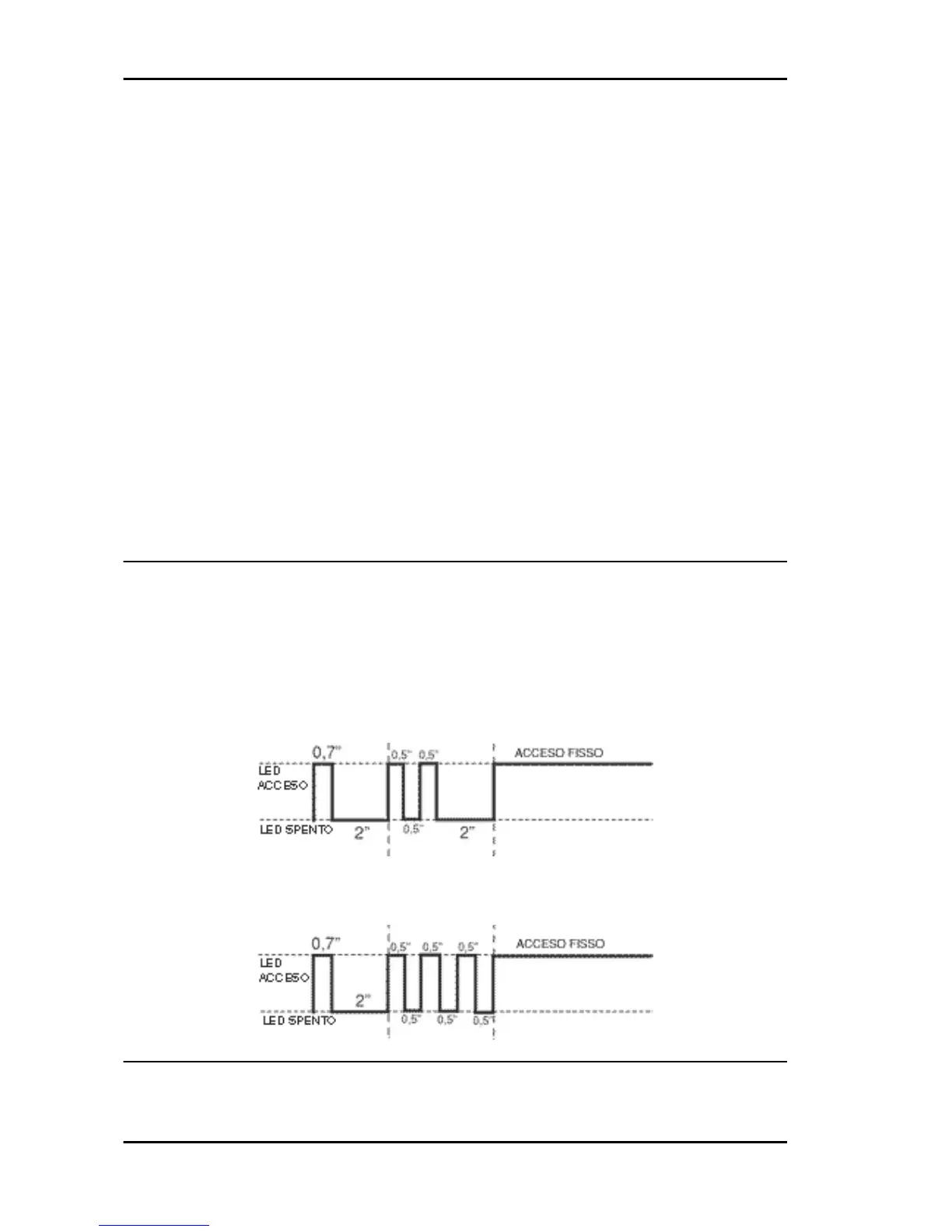

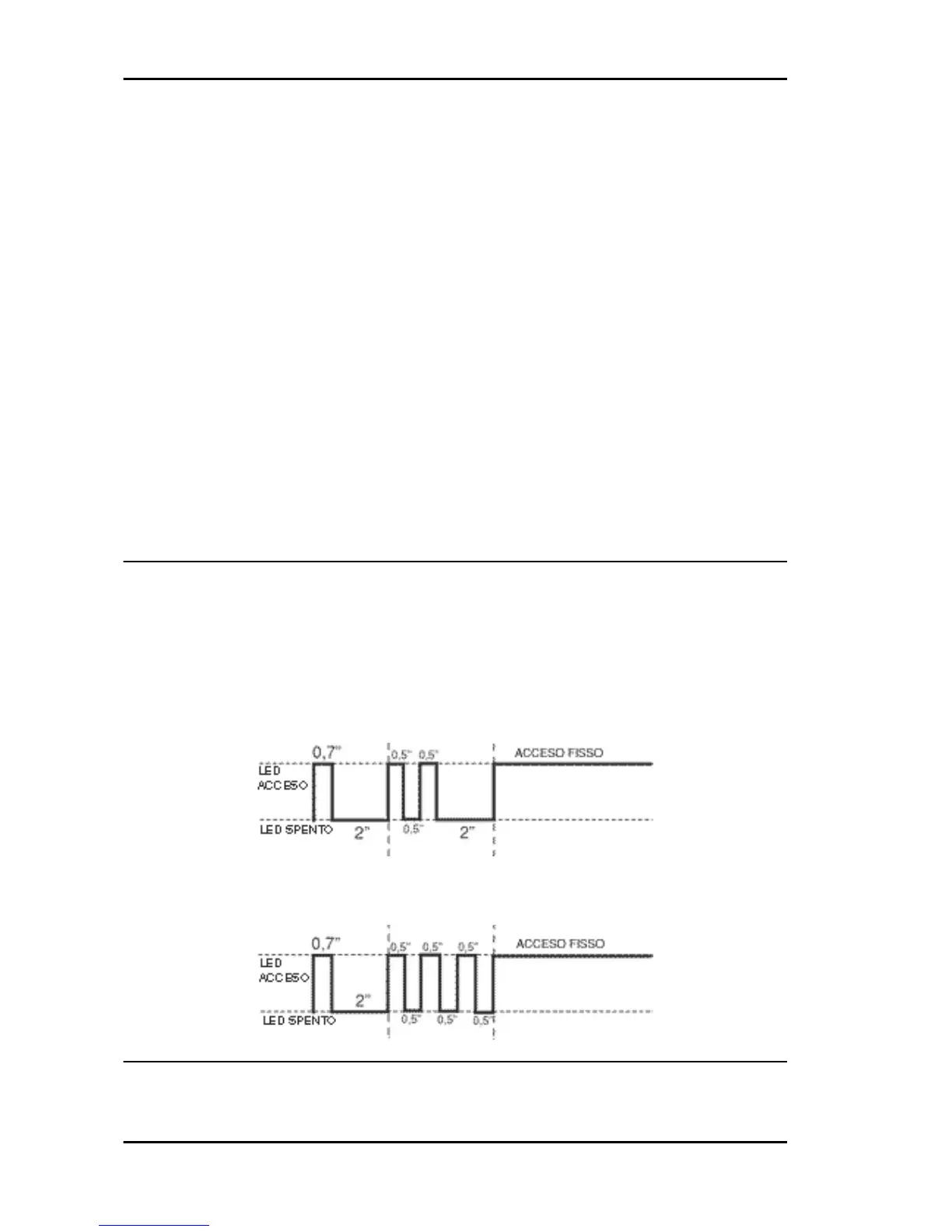

The flash indicating the switching to "ON" can be followed by a phase of programmed failure warnings.

That is, the led is off for 2 seconds, and then diagnosis codes are transmitted with 0.5-second flashes.

After the failure code indication, a steadily on LED signals that ignition is disabled; see the table:

2-FLASH CODE - Example with programmed control unit, no transponder and/or malfunctioning aerial.

Ignition disabled-Vehicle immobilised

3-FLASH CODE - Example with programmed control unit, aerial working properly and unknown trans-

ponder code. Ignition disabled-Vehicle immobilised

Diagnostic code - 2 flashes

Diagnosis code: 2-flashes

Electrical system MSS X9 Evolution 250

ELE SYS - 62

Loading...

Loading...