Secon 11

Integra 3™ Care and Maintenance

Research Instruments Ltd

11

The SAS-SE has been designed to reduce wear on the O-ring so that

replacement needs to be done less frequently. If you suspect that

replacement is necessary, please contact RI as the replacement procedure

is more complicated than for the SAS.

Do not use oil or media in the SAS syringes

If oil or media is introduced into the system it will need to be dismantled

and cleaned. This should be entrusted to an RI-authorised technician

only.

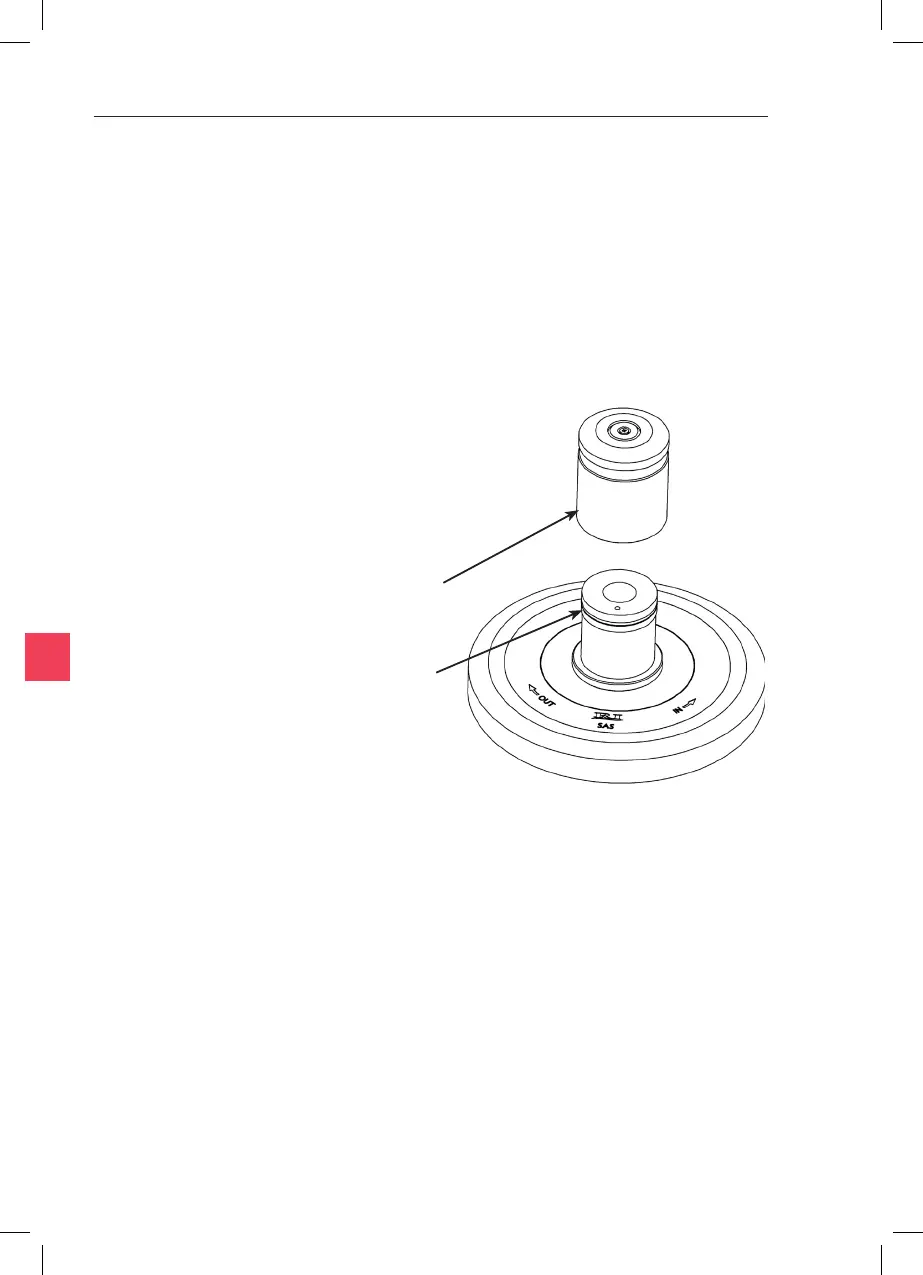

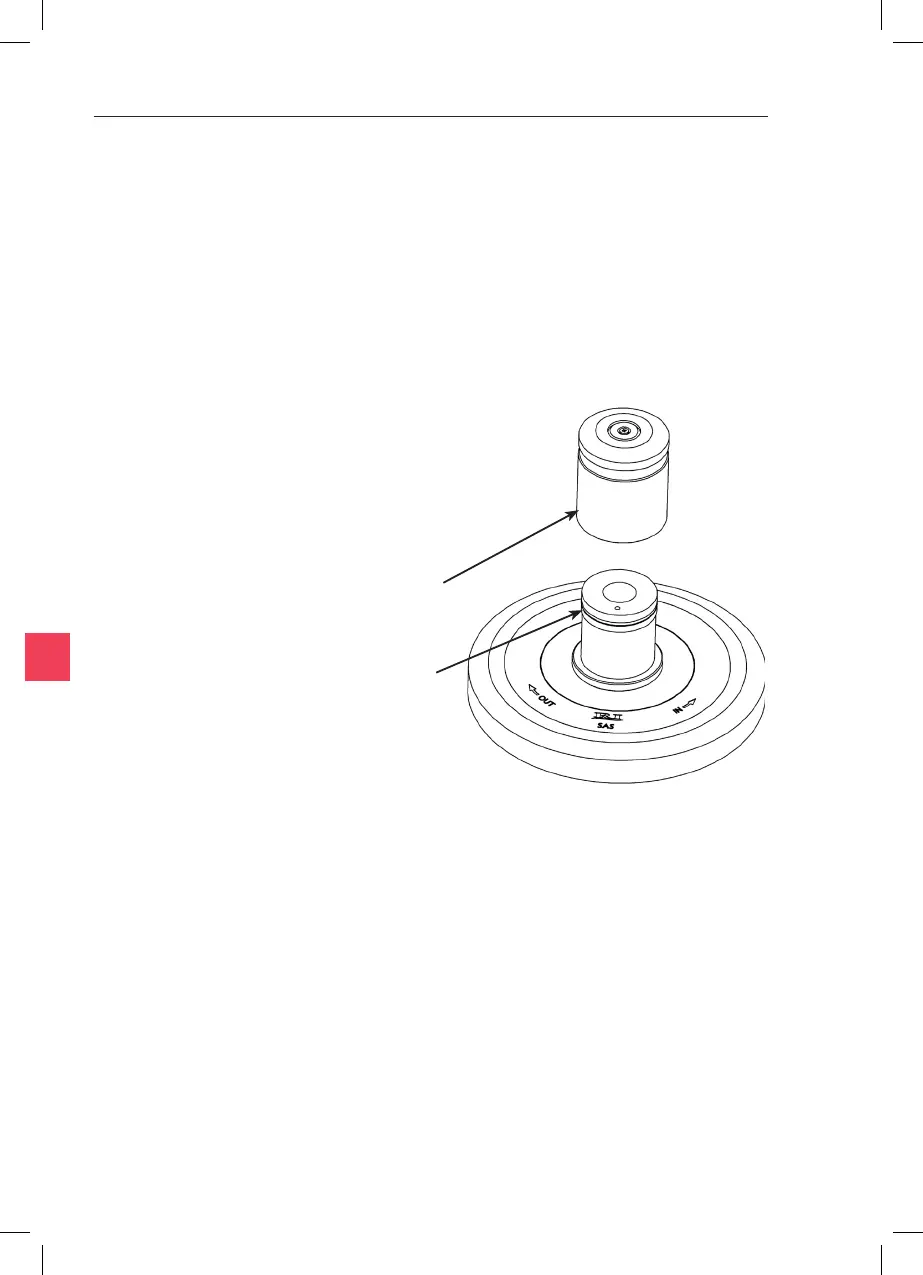

Top

O-ring (in its

groove)

Aer a lot of use the O-ring may need replacing to ensure smooth and

accurate operaon. Spare O-rings are supplied with the syringe, and can

also be ordered from RI.

1. Unscrew the top of the syringe to reveal the black rubber O-ring. The

O-ring is ed in a groove in the lower part of the syringe.

2. Carefully remove the O-ring.

3. Place the new O-ring in the

groove.

4. Reassemble.

Figure 11-3

Following replacement of the O-ring and before pung into service, test

the SAS in a manner representave of normal use.

Loading...

Loading...