7.5 Process Control

Item Description Setting Method

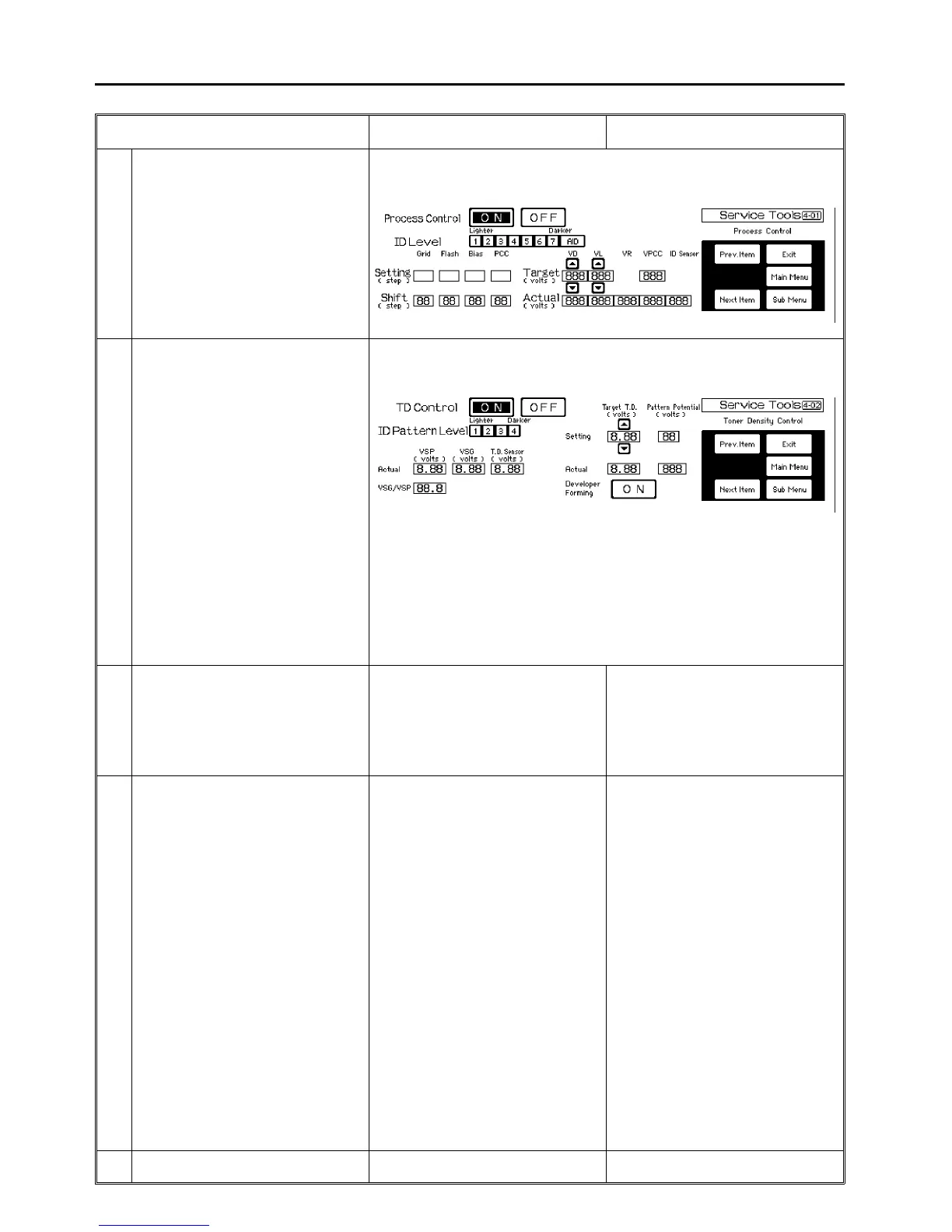

4-01 Process control The data for the process control can be

seen and adjusted. For details, see 4.1

Display with Service Tools.

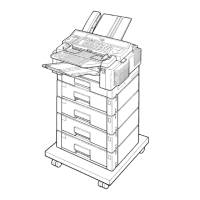

4-02 Toner density control The data for the toner density control can

be seen and adjusted. For details,

see 4.1 Display with Service Tools.

CAUTION:

Unlike the developer forming key in

service tool 3-04, the developer forming

"ON" key in this screen changes the data

for the "Target T.D.". Use this key only

when setting C is carried out. For usual

developer forming, use the key in service

tool 3-04.

* Changing the ID sensor pattern level (1

to 4) will change the toner density of the

developer.

4-03 AID reference voltage By pressing the Start key, the potential

sensor measures the image density of

the original placed on the exposure glass

10 times. (The data is used for the AID

level selection.) The voltage is shown 10

times with the development bias steps

that is raised by the determined AID level.

Press [4-03] of the process control menu.

⇓

Place the PC-1 chart on the exposure

glass and press the Start key.

4-04 OPC cleaning operation (1) The OPC cleaning operation interval

can be selected.

* if the copy volume is extremely high or

low and dirty background copies appear,

set the interval to 5K.

Initial setting: 10K

(2) The manual ON key is used to do

OPC cleaning.

* It takes about 5 minutes to clean one

round of the OPC belt.

(3) The OPC belt forming ON key is the

same function as that of the screen

[3-04].

* In this mode, OPC belt turns 10

rotations with the OPC cleaning ON.

CAUTION:

Do not stop the OPC cleaning operation

midway. The OPC belt will have an

insufficiently cleaned part, and this may

appear on the copy image.

Press [4-04] of the process control menu.

⇓

Select "OFF/5K/10K/20K".

4-05 Utility Extra functions can be selected. Refer to

Utility modes section for details.

1 July 1994 Process Control

7-13

Loading...

Loading...