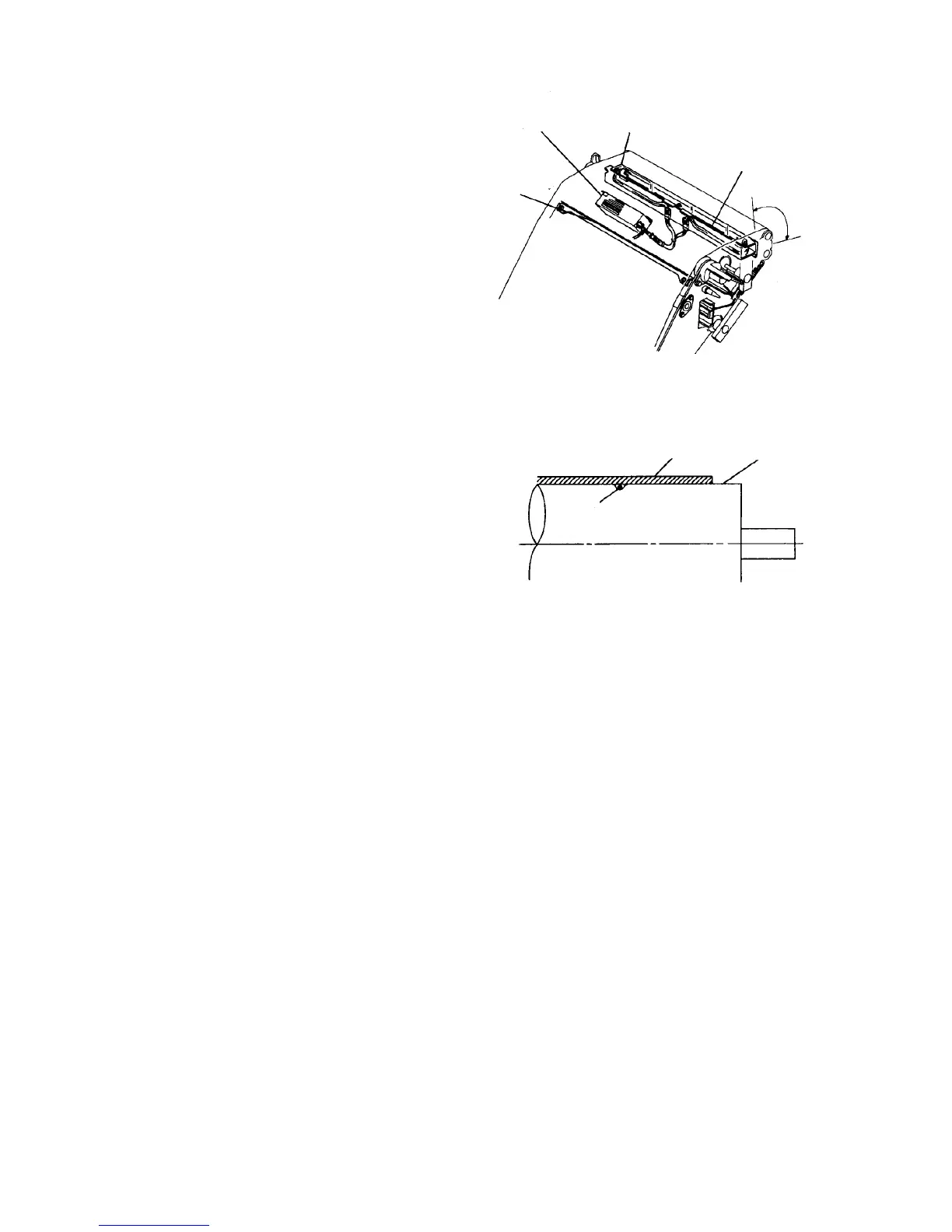

2.3.5 Discharge mechanism

The residual charge of the OPC surface is removed from

the inside of the unit by the quenching lamp (fluorescent

lamp). Since the belt is illuminated from the inside, the

charge is removed regardless of the influence of the

toner setting on the OPC surface. The light of the lamp

is applied from the T/S corona unit to the cleaning roller,

thus enhancing the transfer efficiency and cleaning

efficiency.

The area exposed to light from the lamp is covered with

a transparent, yellow cover (filter) to protect the OPC

belt against harmful ultraviolet radiation that can cause

optical fatigue.

The discharge brush removes the charge on the OPC

belt (base) produced by friction during operation. This

prevents electric shocks to technicians when they

perform maintenance on the machine.

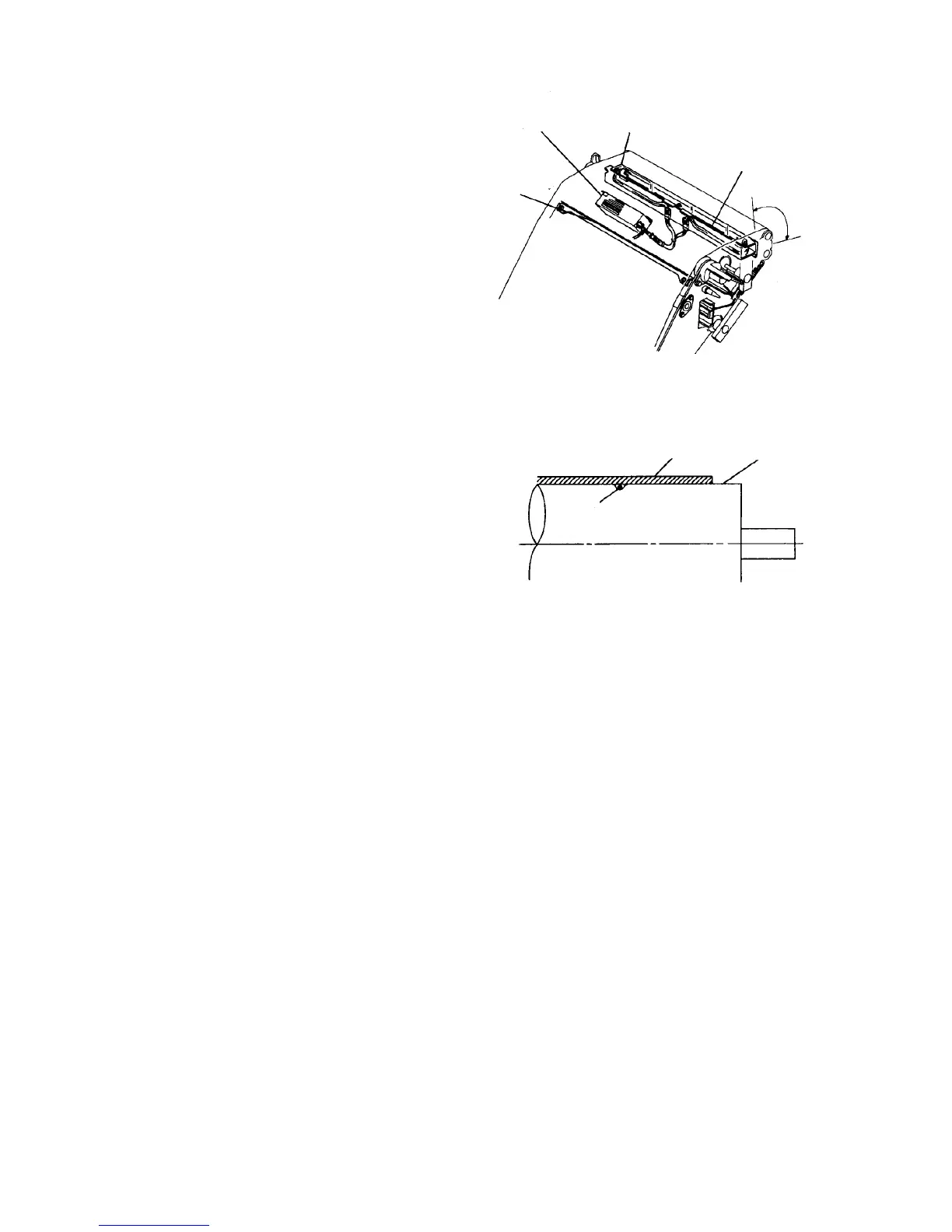

2.3.6 OPC belt damage prevention mechanism

Rubber rollers are used in the OPC unit. When

developer or cleaning carrier enters the rear of the OPC

belt, the developer or cleaning carrier transfers to the

roller surface. This prevents the carrier from damaging

the OPC.

All rollers other than the drive roller use low-friction

rubber to help slipping of the belt during tracking.

Discharge

brush

QL stabilizer

Lamp cover

Quenching lamp

LIght

output angle

OPC

Belt roller

Developer

Loading...

Loading...