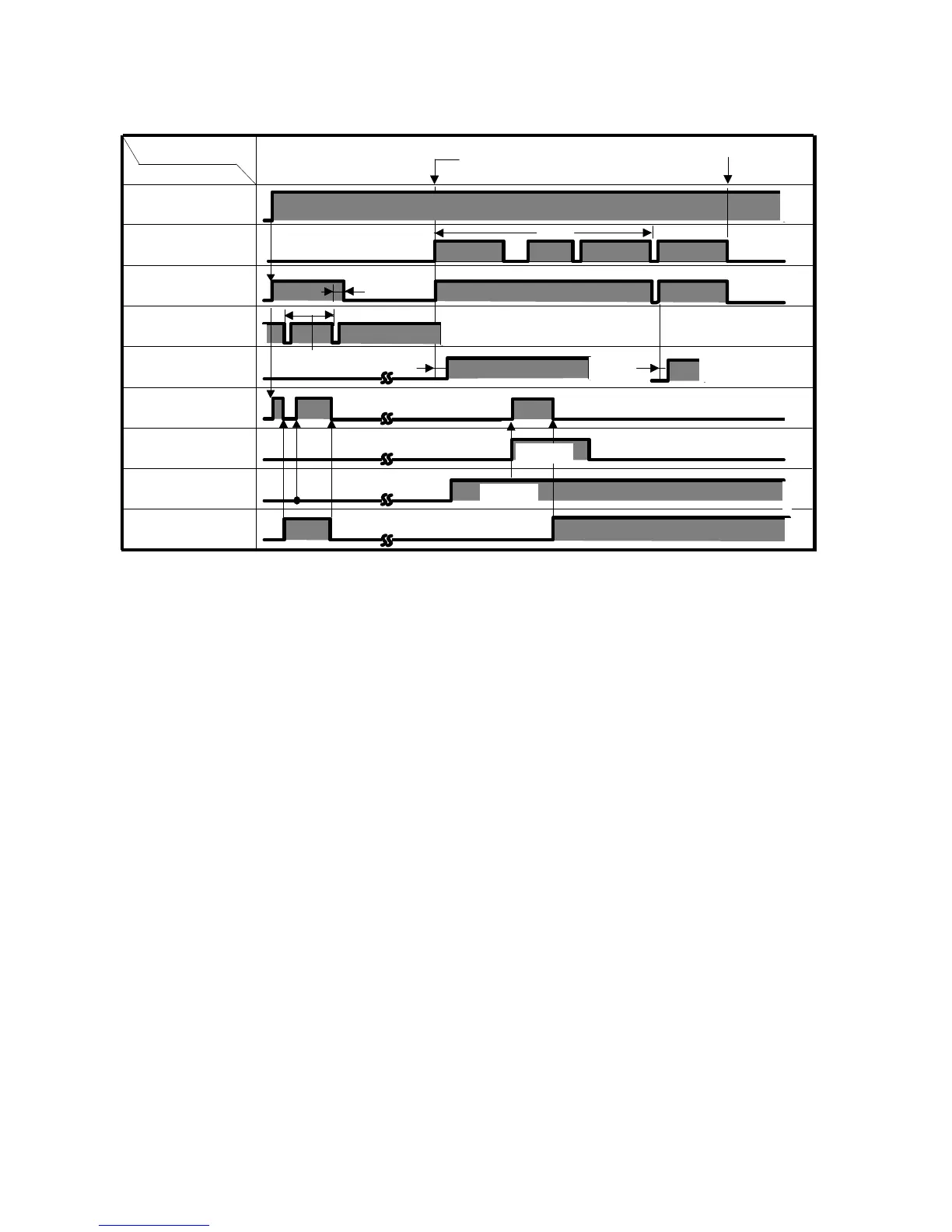

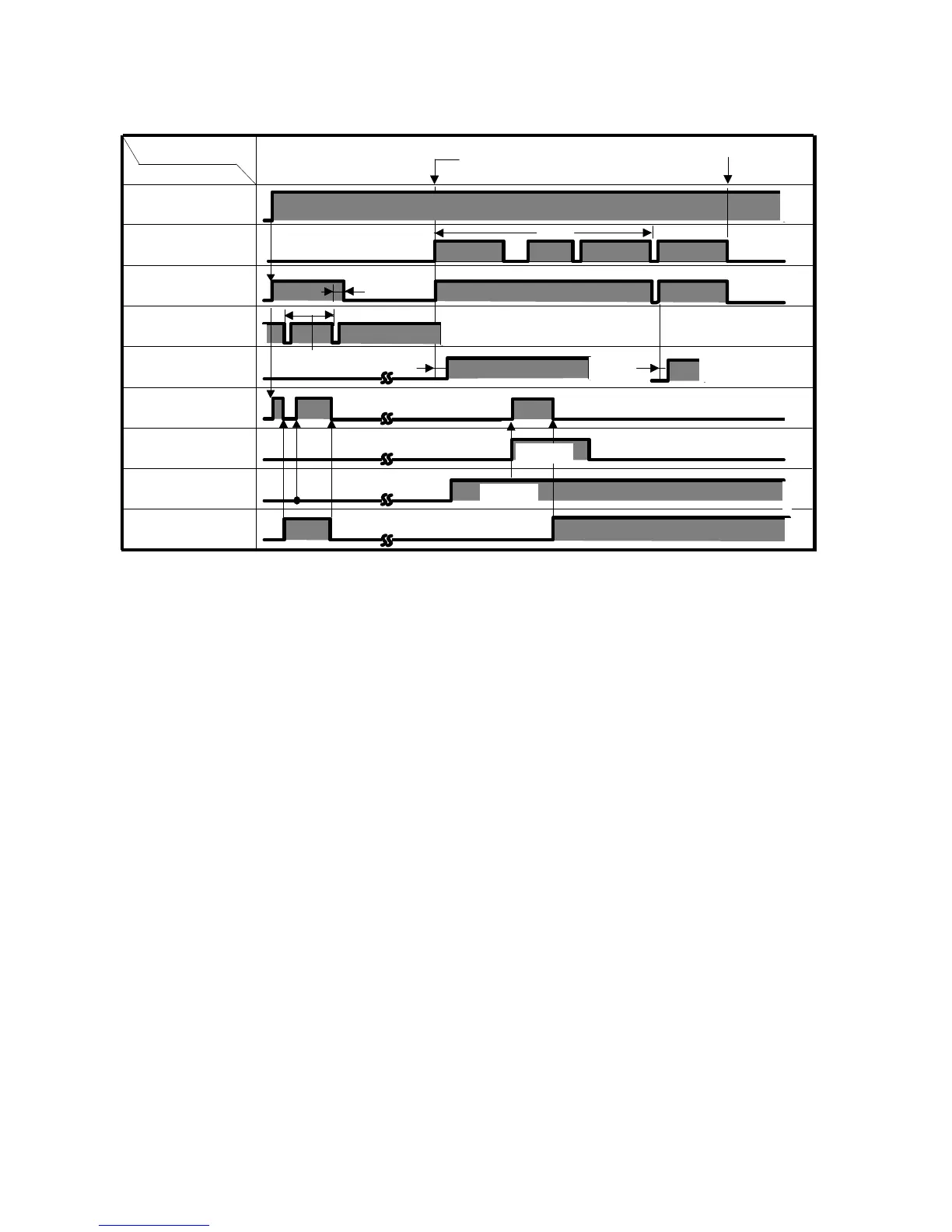

2.3.10 Timing chart

Operation before the copy stand-by

Description

❈1 The OPC home mark is detected twice to determine the length of one belt cycle, counting the

number of clock pulses of the OPC motor encoder from the first detection to another.

The segments are equally divided according to size, and each segment position is also

determined by this pulse count.

❈2. Turning the tracking motor on for the first time detects the sector sensor.

❈3. The sector sensor also identifies the tilt direction of the tracking rollers. Therefore, if the

signal from the edge R or F does not meet the direction for offset correction, the tracking motor is

turned ON again to reverse the offset correction direction.

❈4. When the fusing temperature reaches 175°C, the OPC motor starts turning, then stops (OPC

idling mode). During this period, the main motor repeats turning on and off three times. The first

rotation is to feed out any sheets in the paper path of the machine if there are any. If some sheets

of paper remain on the paper path, this feeds out the paper. The second rotation is to measure V0

(basic OPC potential) to do the OPC rest time compensation. The third is to measure VR (OPC

residual potential). After that, the main and OPC motors turn on and off once more to make and

measure the ID sensor pattern. Then, the machine enters the copy stand-by mode.

Timing

Item

Main switch

Main motor

OPC motor

OPC mark sensor

Quenching lamp

Tracking motor

Rear edge sensor

Front edge sensor

Sector sensor

L

H

L

L

H

H

H

0.7 sec0.7 sec

0.2 sec

ID sensor mode

Copy stand-by

Shield

OPC idling mode

Shield

175 ° (Fusing temperature)

1 OPC belt rotation

❈4

❈2

❈3

❈1

Loading...

Loading...