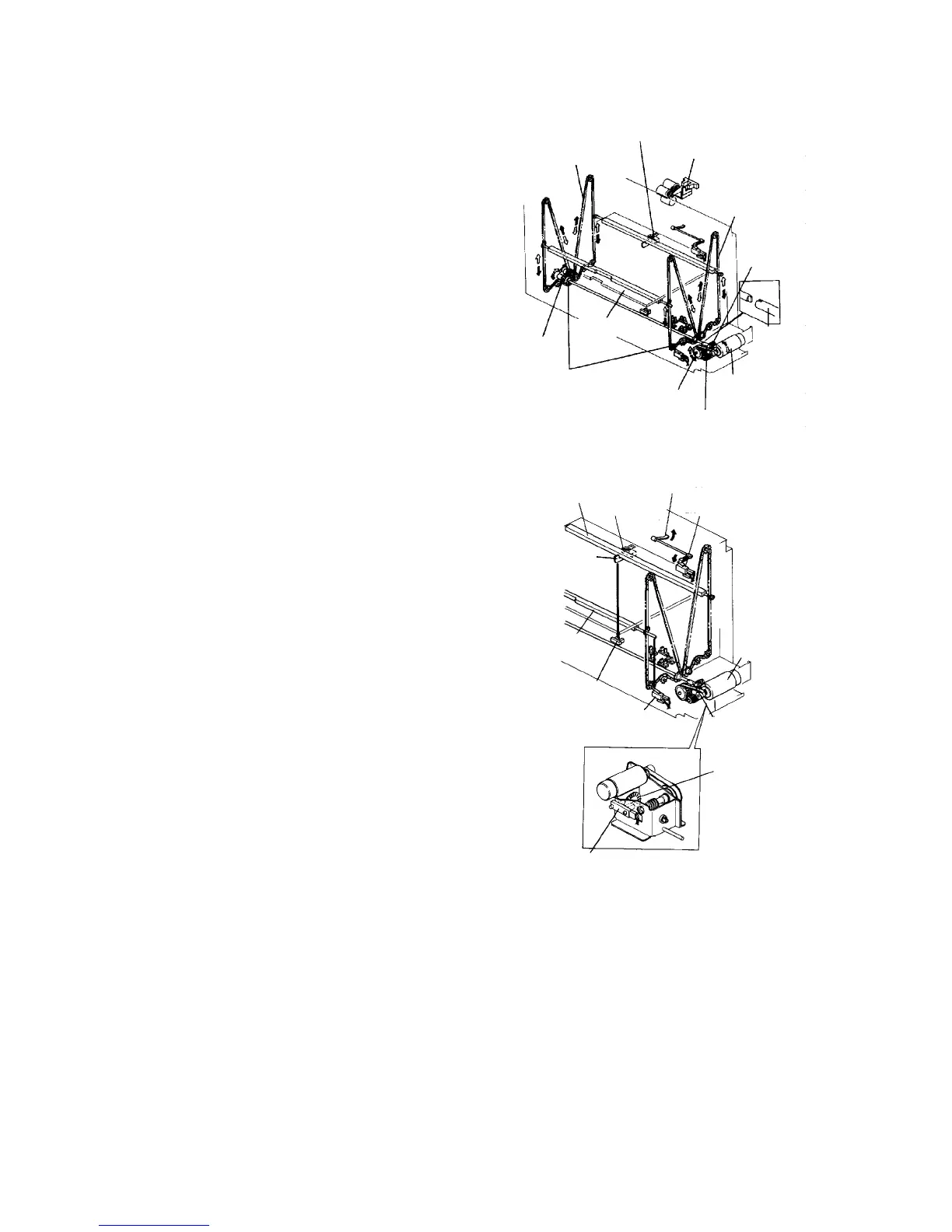

2.16.2 Tray drive mechanism

Raising and lowering of the LCT bottom plate is done by

the tray motor, a dc servomotor. The drive train is

illustrated in the diagram.

Paper end detection

The paper end sensor (a reflective photosensor) detects

the paper end. When paper ends, the LCT bottom plate

is lowered.

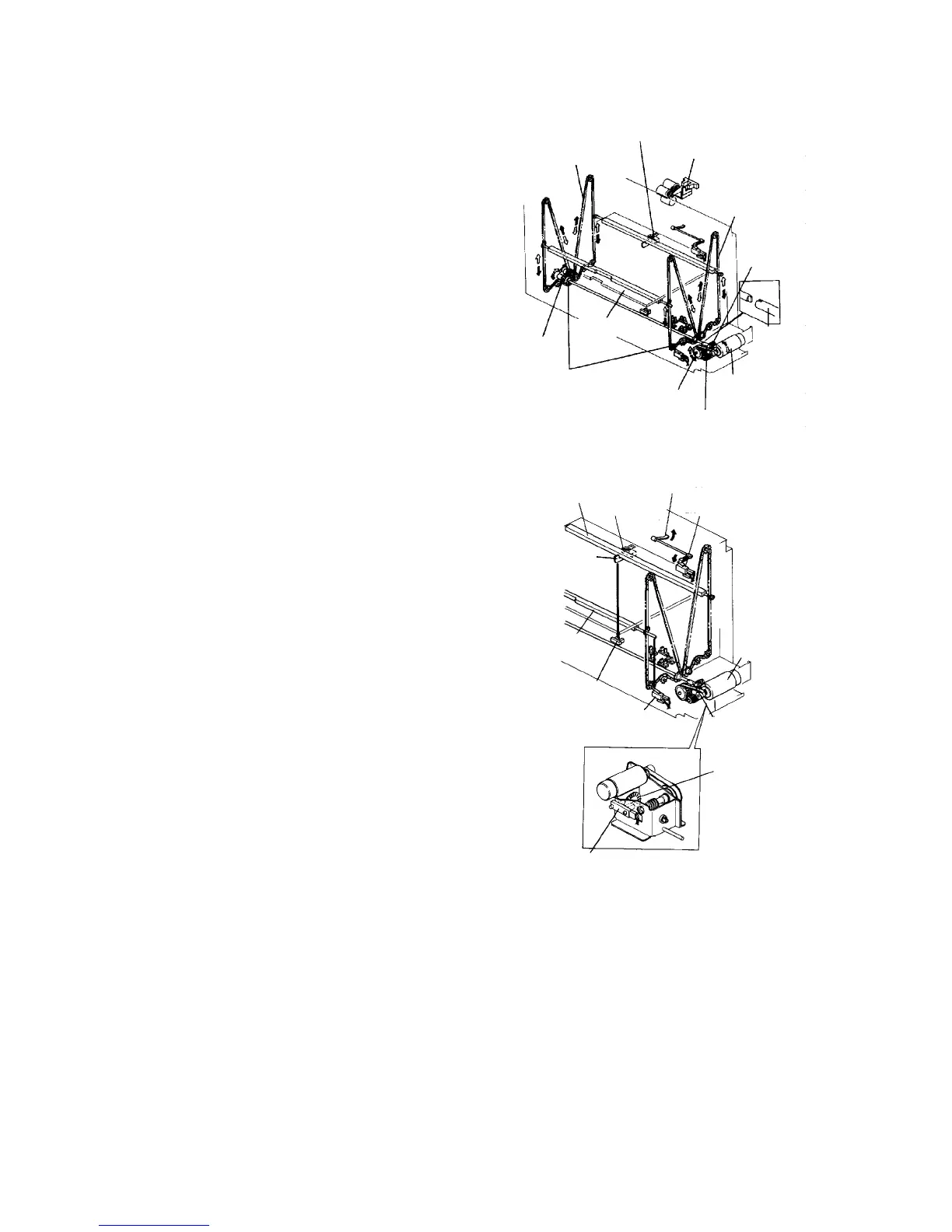

Upper and lower limit detection

The upper limit sensor detects the upper limit of the tray

and the lower limit sensor detects the lower limit. This is

the same as the mechanism used in the main body tray.

The lower limit sensor is activated when the bracket of

the paper end sensor interrupts the lower limit sensor,

and the motor stops.

Overrun switches are provided for the upper and lower

limits. When the upper limit feeler is lifted by the paper,

the upper overrun switch is turned ON. Then, the motor

stops.

When the right bottom plate support shaft turns the

lower overrun switch ON, the motor stops.

Tray drive chain

Paper end sensor

Upper limit sensor

Tray drive chain (rear)

Worm gear

Worm gear shaft

Tray motor

Timing belt

Pulley (50T)

Sprocket (14T)

Gear (27Z)

LCT

bottom

plate

End sensor bracket

Left bottom plate

support shaft

Paper

end

sensor

Upper limit feeler

Upper overrun switch

Tray motor

Worm gear shaft

Pulse generator disk

Paper volume sensor

Lower overrun switch

Lower limit sensor

Right bottom plate

support shaft

Loading...

Loading...