Chapter 2

TECHNICAL INFORMATIONS

- 7 -

English

C224153200.fmIDM

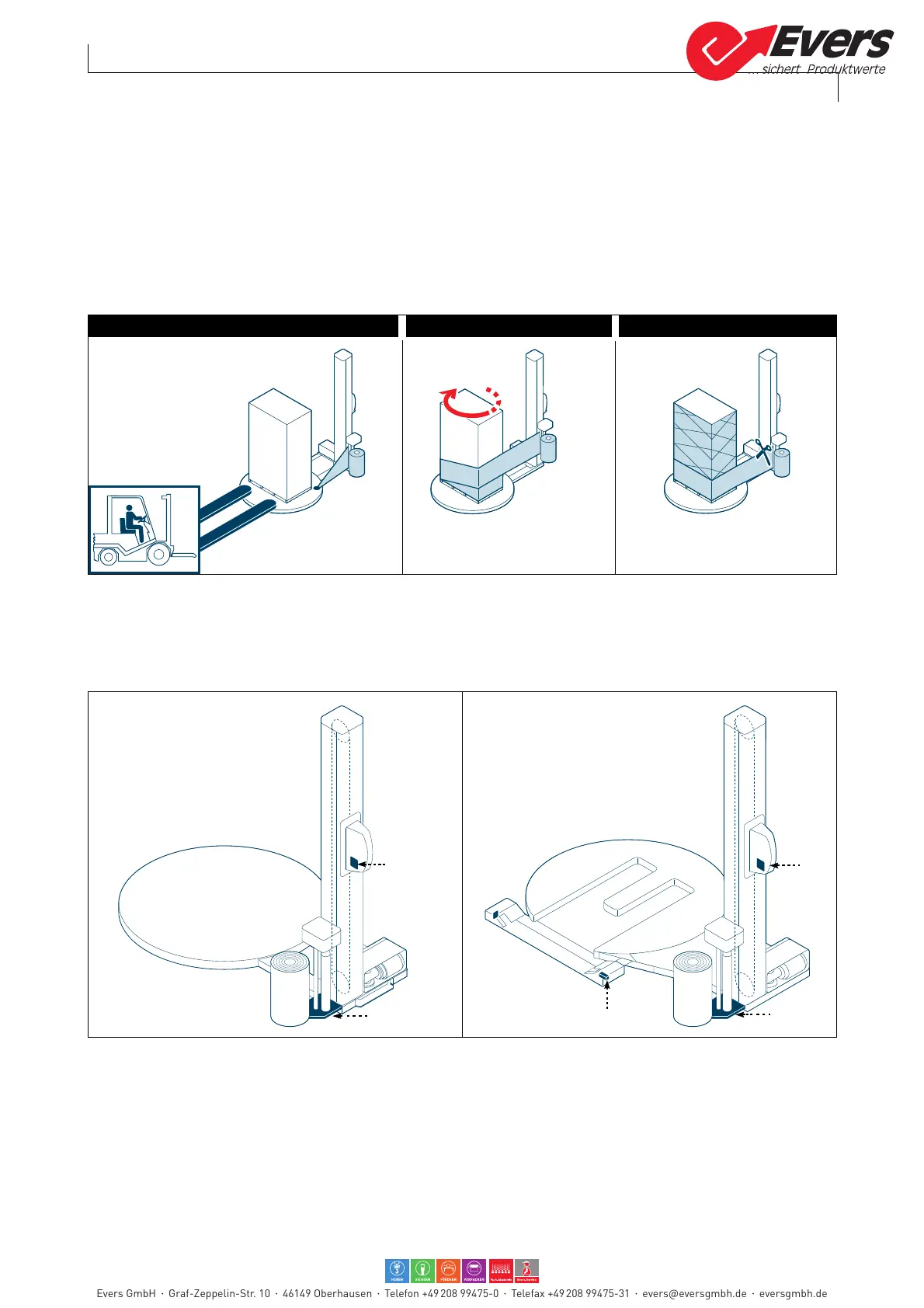

2.3. WORKING CYCLE

–Step 1: the operator loads the pallet on the rotary table and fixes the film to the prod-

uct.

–Phase 2: once the cycle has started, the rotating table starts to turn while the reel

carriage unwinds film according to the set parameters.

–Phase 3: once the wrapping has been completed, the machine manually cuts the film

and stops.

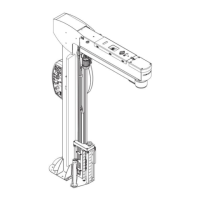

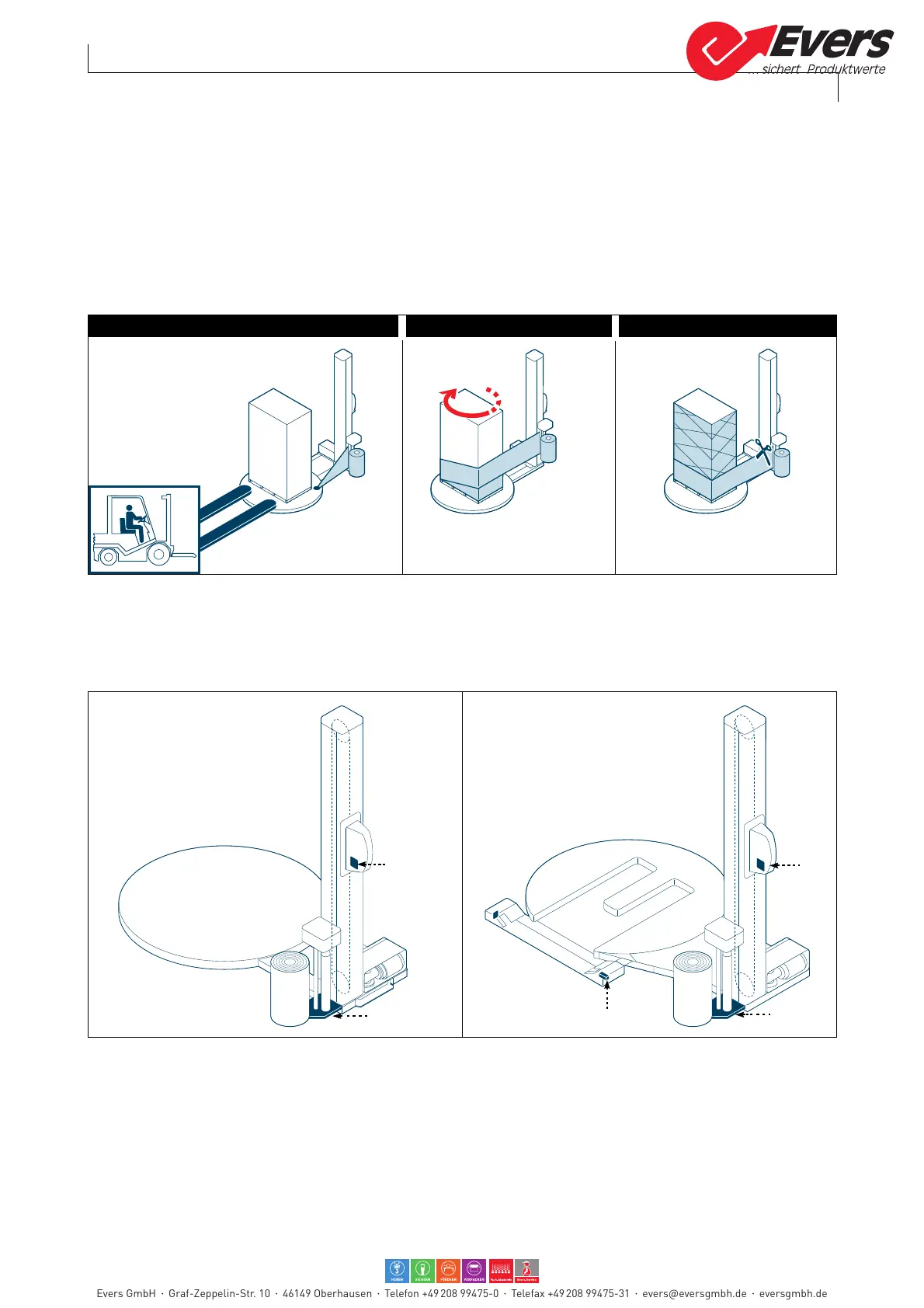

2.4. SAFETY DEVICES

The figure shows the positioning of the devices on board of the machine.

A)Reel carriage base micro switch: stops the descent when there are obstacles un-

der the carriage.

B)Main switch: to turn the electric supply on and off. It can be padlocked to prevent

unauthorised personnel from starting the machine during adjustments and mainte-

nance.

C)Fork entry photoelectric cell: detects the presence of the forks on the pallet un-

loading/loading ramp, and stops the table rotating. (Only for machines model "Eco-

plat TP FRD - Ecoplat TP RS - Ecoplat TP PPS")

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...