Chapter 6

INFORMATION ON USE

- 30 -

English

C624153200.fmIDM

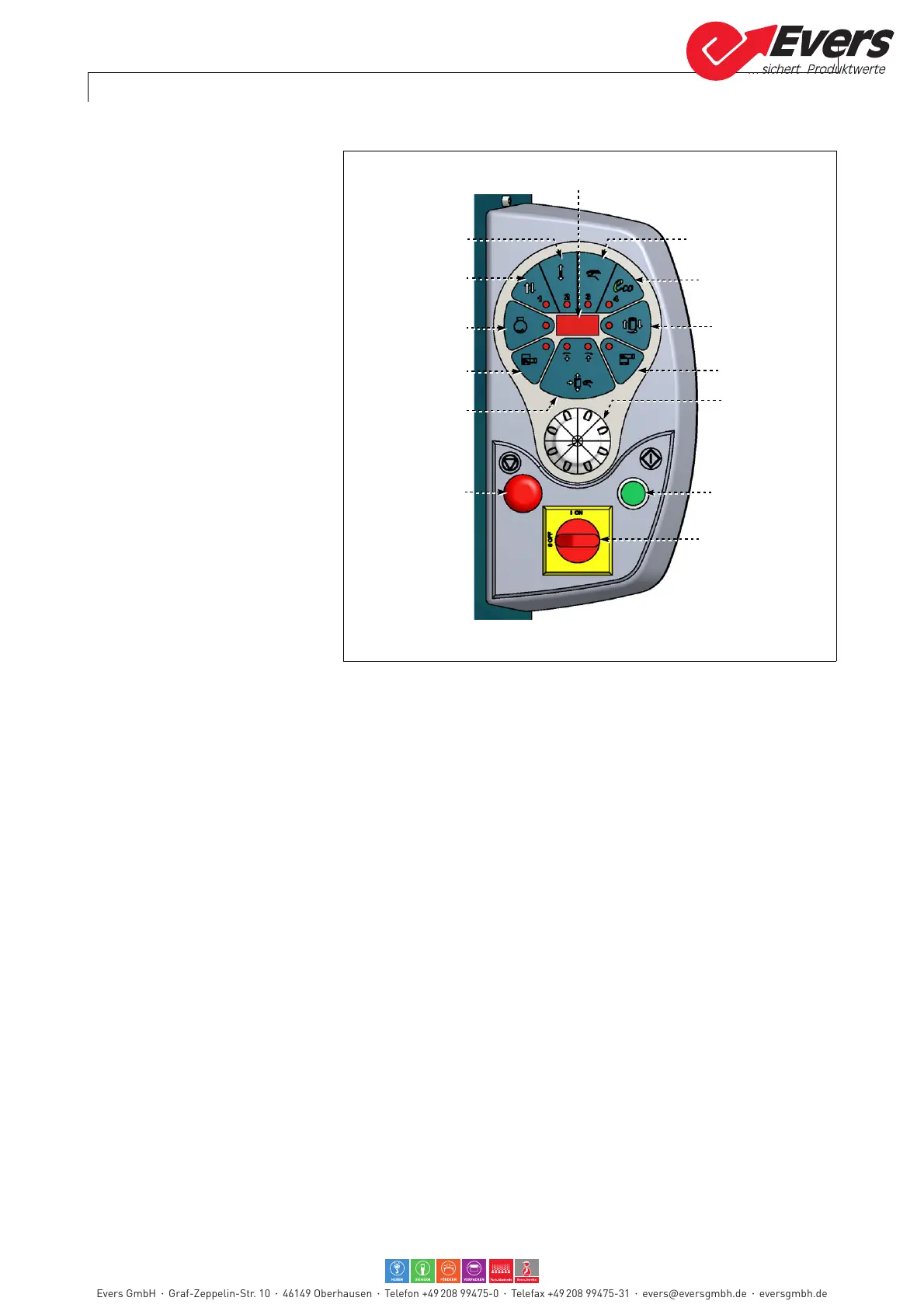

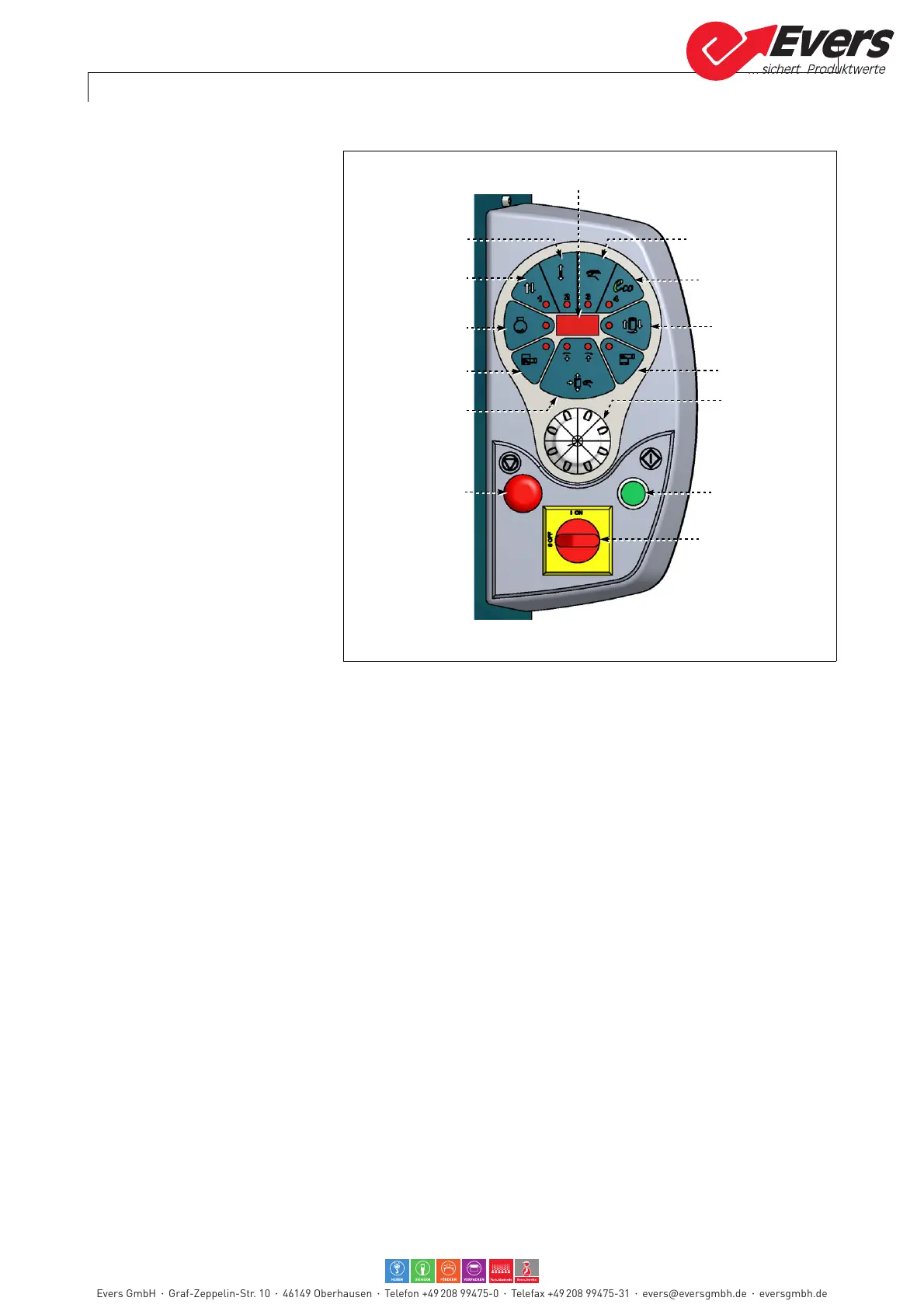

6.3. CONTROL DESCRIPTION (SERIES ECOPLAT)

The figure shows the major control

units.

A)Main switch (lockable): turns

the main power supply on and

off.

B)"Cycle start" button: to start

the automatic wrapping cycle.

C)"Stop cycle" button: to stop

the automatic wrapping cycle.

D)Multi-function selector: starts

and programs the machine func-

tions.

Rotate selector (clockwise or

counter-clockwise) and release

when the LED of the desired

function turns on.

E)Digital display: displays the op-

erating parameters and the

alarm signals.

Functions "Type of wrapping"

–F1 Function "Double cycle": selects a double wrapping cycle.

The reel carriage moves off from the bottom of the pallet and stops when it gets to

the top, and then comes back down to the bottom of the pallet again, wrapping the

load twice in doing so.

–F2 Function "Simple cycle": selects a simple wrapping cycle.

The reel carriage moves off from the bottom of the pallet and stops when it gets to

the top, after having performed the set number of bottom and top wrappings of the

pallet.

If the "Start" button is pressed again, a second simple wrapping cycle is carried out

starting from the top with descent to the base of the pallet.

Otherwise, with function "F7", the reel holding carriage can be lowered.

–F3 Function "Manual cycle": selects the manual wrapping cycle.

The vertical movement of the reel holding carriage must be activated manually by the

operator.

–F4 Function "Eco": selects the cycle of custom-made wrapping (Economic/Eco-

friendly)

Functions "Production parameters" and "Manual movement of the carriage"

–F5 Function "Carriage rise/descent speed" adjusts the speed of the vertical

movement of the reel holding carriage.:

–F6 Function "Upper wraps": programs the number of wraps in the upper part of the

pallet.

A

B

F6

F5

F4

C

F8

F9

F1

F7

F2

F3

E

IDM-24153202000.tif

D

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...