- 29 -

English

C624153200.fmIDM

Chapter 6

INFORMATION ON USE 2

6.1. RECOMMENDATIONS FOR USE AND FUNCTIONING

Accident frequency derived from machine use depends upon many factors that

cannot always be foreseen and controlled. Some accidents can depend upon

unforeseeable environmental factors; others depend especially upon the user's

behaviour. In addition to being authorised and appropriately informed, on first

use personnel must simulate some manoeuvres to identify the main commands

and functions. Only carry out the operations foreseen by the manufacturer and

do not tamper with any device to obtain performances other than those provid-

ed. Before use, check that the safety devices are correctly installed and effi-

cient. Users, in addition to striving to satisfy these requirements, must apply all

the safety regulations and carefully read the descriptions of the controls and

start up.

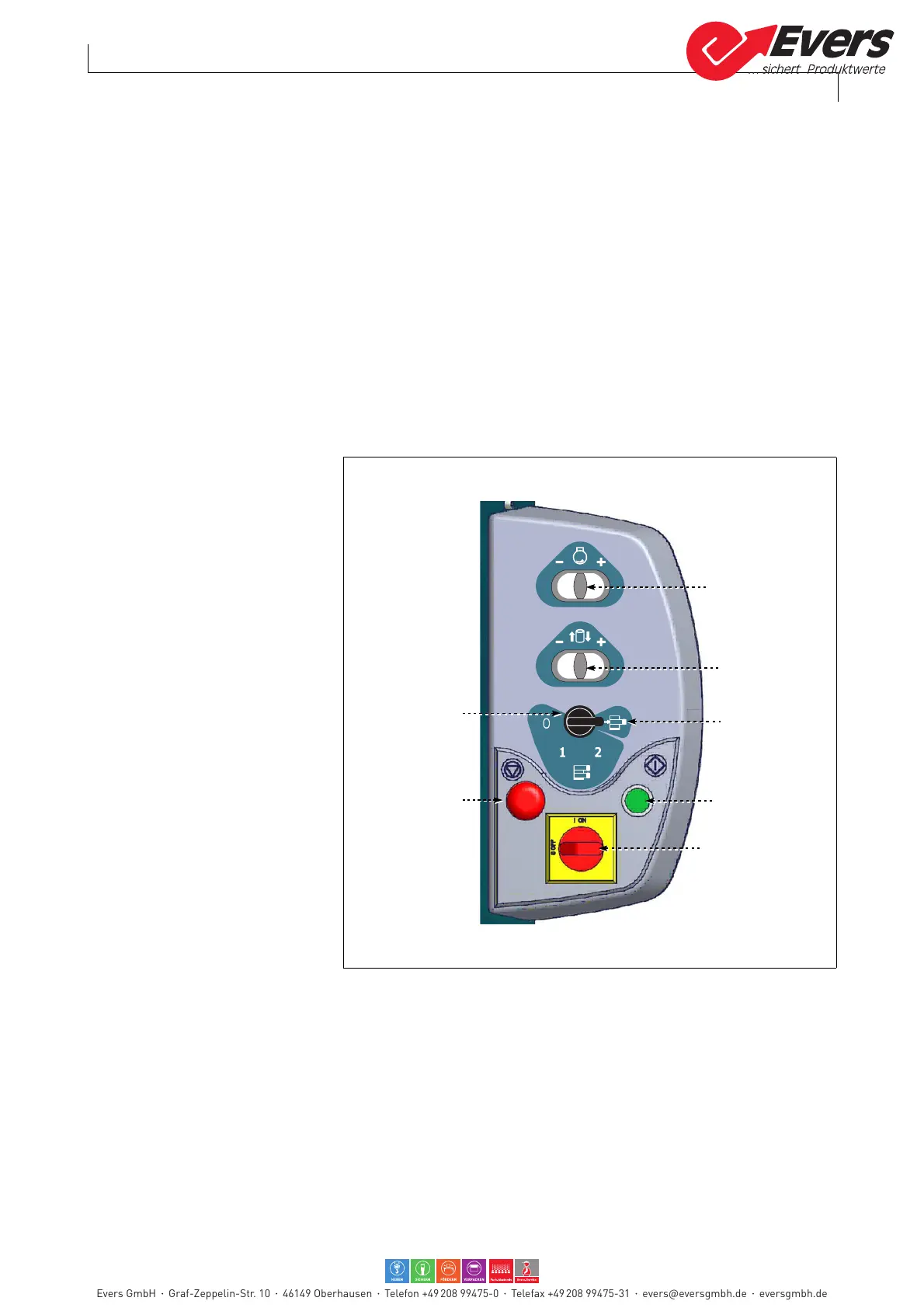

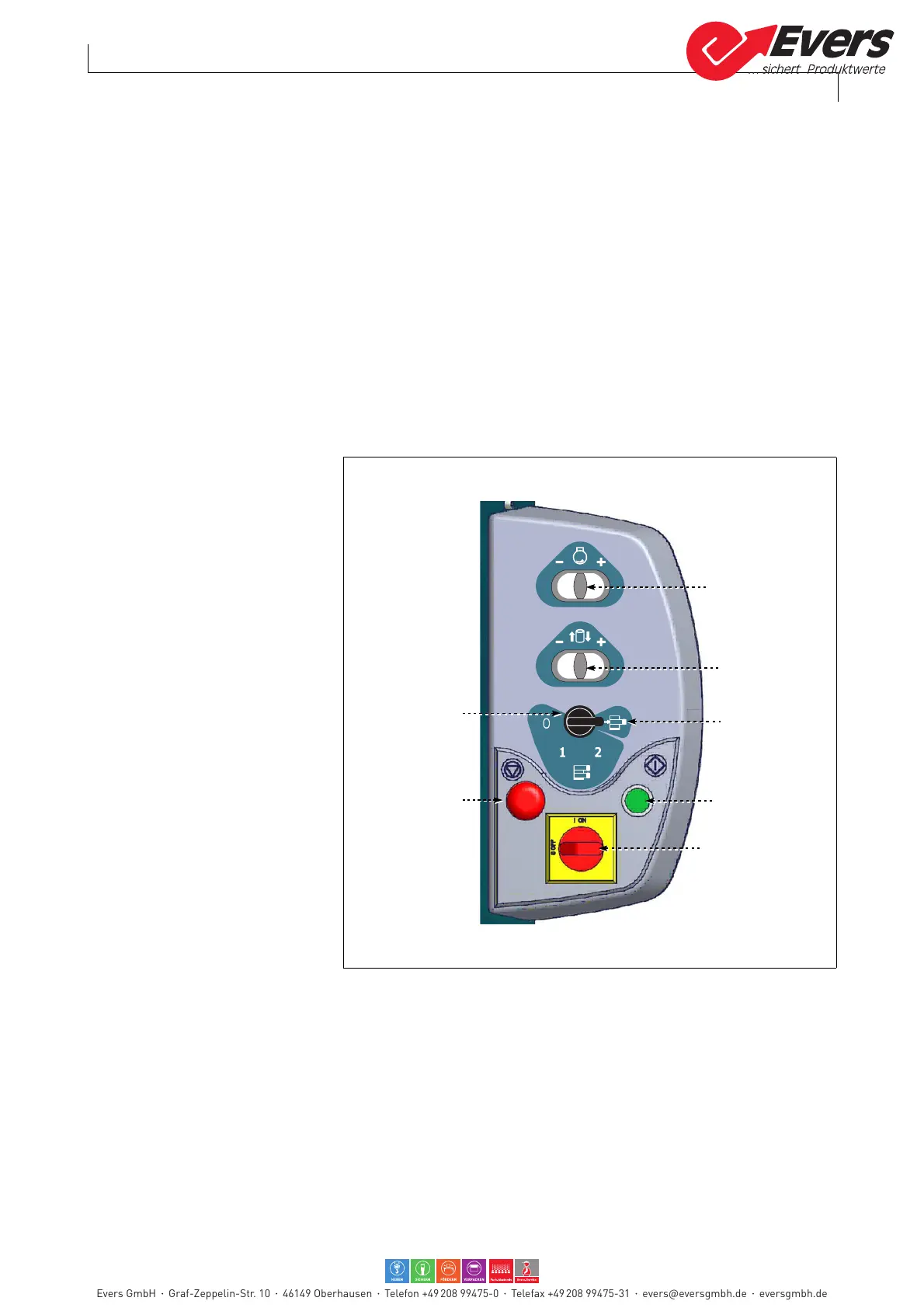

6.2. CONTROL DESCRIPTION (ECOPLAT BASE)

The figure shows the major control

units.

A)Main switch (lockable): turns

the main power supply on and

off.

B)"Cycle start" button: to start

the automatic wrapping cycle.

If the warning light of button is

on, the power supply is activated

C)"Stop cycle" button: to stop

the automatic wrapping cycle.

D)"Top and bottom wraps" se-

lector: sets the number of wraps

(top and bottom) of the pallet.

- Position 0: no wraps

- Position 1: one wrap on the up-

per and lower part

- Position 2: two wraps on the up-

per and lower part

- Position D1: backing wrap

With selector in position "D1",

reel holding carriage stops in

order to perform the backing

wraps.

As long as selector stays in posi-

tion "D1", the warp is performed in the same point.

Bring selector to one of positions "0-1-2" in order to restart the reel holding carriage.

E)"Carriage up/down speed" button: to adjust the reel carriage lifting and lowering

speeds.

F) "Table rotation speed" button: to set the rotation speed of the rotating table.

F

E

B

A

C

IDM-24153201900.tif

D1

D

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...