Chapter 6

INFORMATION ON USE

- 35 -

English

C624153200.fmIDM

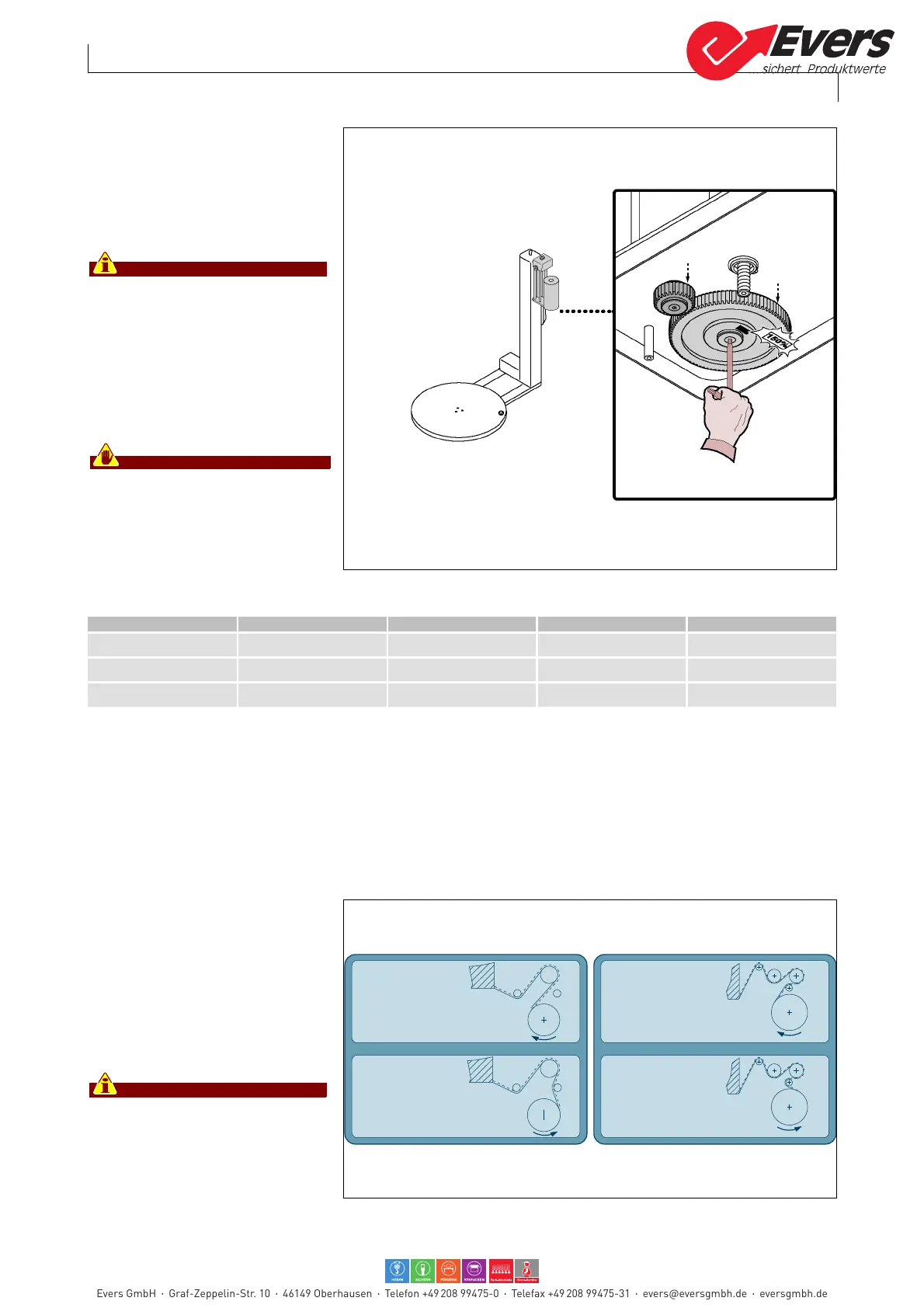

6-Replace toothed wheels (Z1-

Z2) according to the desired

pre-stretch percentage.

The table lists the pre-stretch

values obtainable with the

proper transmission ratios.

Set pre-stretching according to

film resistance and quality to ob-

tain low consumption.

7-Reassemble the guard (B)

when finished.

8-Start off machine to check cor-

rect operation.

Before restarting the machine,

make sure that no tools or mate-

rial are left near parts in motion.

Only for machines model "Ecoplat RS - Ecoplat TP RS"

Reel carriage is provided with fixed pre-stretch ratio and it is possible to choose among

the available models 30-60-90% when ordering the machine.

To change the pre-stretch value, contact a Service Centre authorised by the Manufac-

turer.

6.9. REEL LOADING

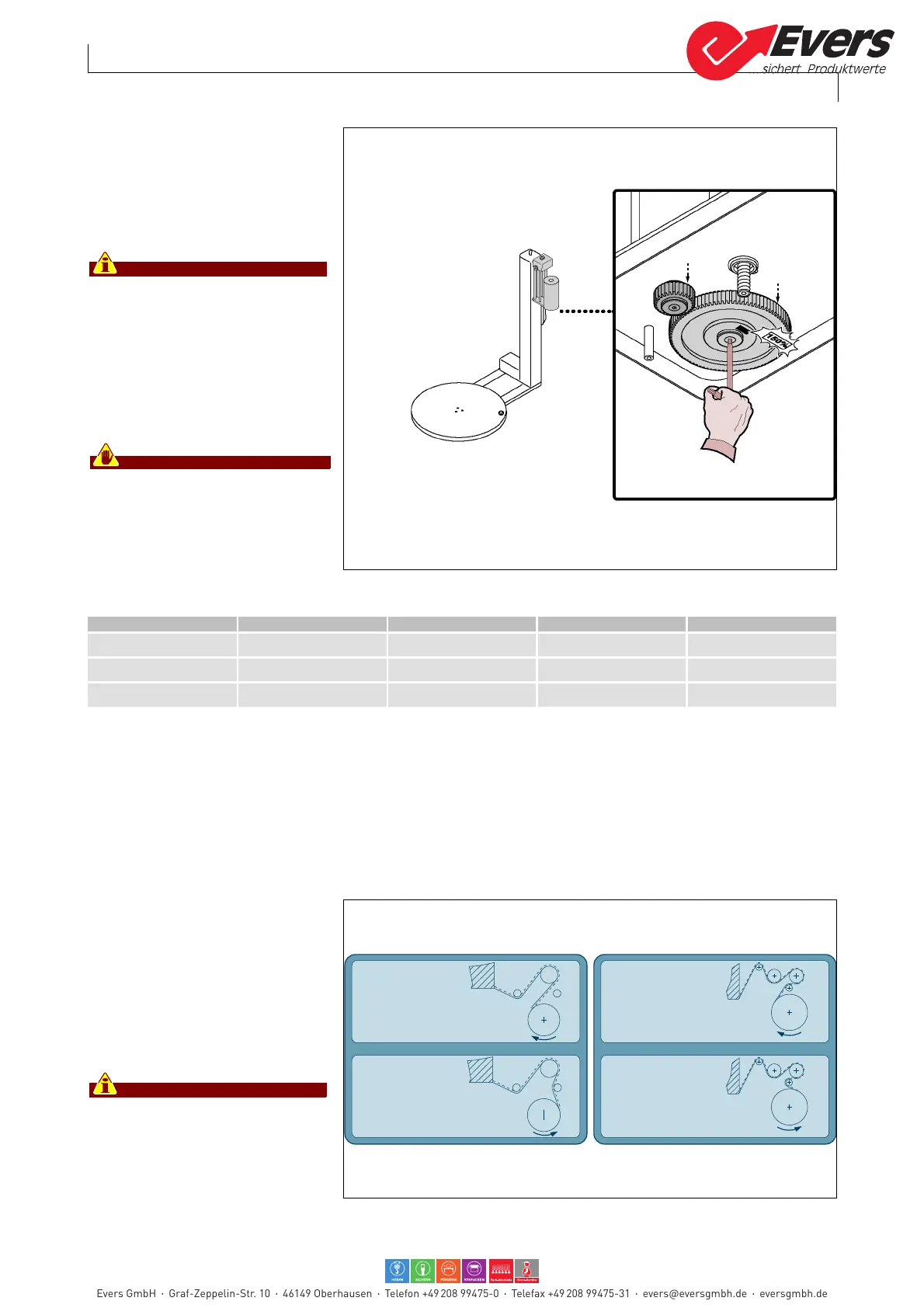

For this operation, proceed in the

following way.

1 -Position the reel with the film in

its housing provided on the reel

carriage.

2-Unwind the film and insert it be-

tween the rollers as shown in

the figure.

The adhesive side of the reel (in-

ternal or external) is shown with

a broken line.

Table 6.1: Pre-stretch values

Pre-stretch percentage Gear code (Z1) Gear teeth nr. (Z1) Gear code (Z2) Gear teeth nr. (Z2)

150% 2540300092 34 2540300091 85

200% 2540300094 29 2540300093 90

250% 2540300088 27 2540300087 92

EXTERNAL GLUE

INNER ADHESIVE

IDM-24153202301.pdf

EXTERNAL GLUE

INNER ADHESIVE

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...