Chapter 6

INFORMATION ON USE

- 32 -

English

C624153200.fmIDM

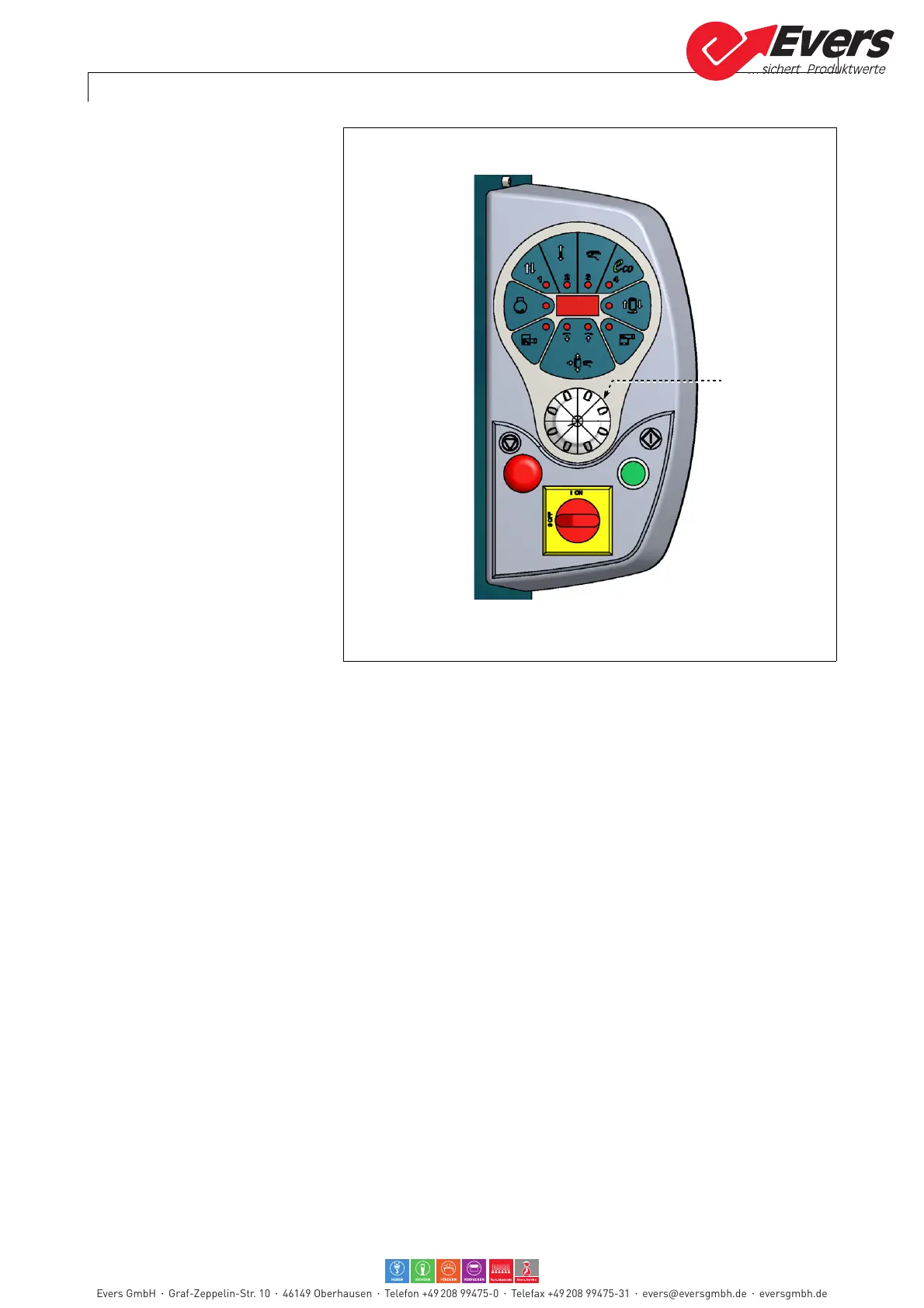

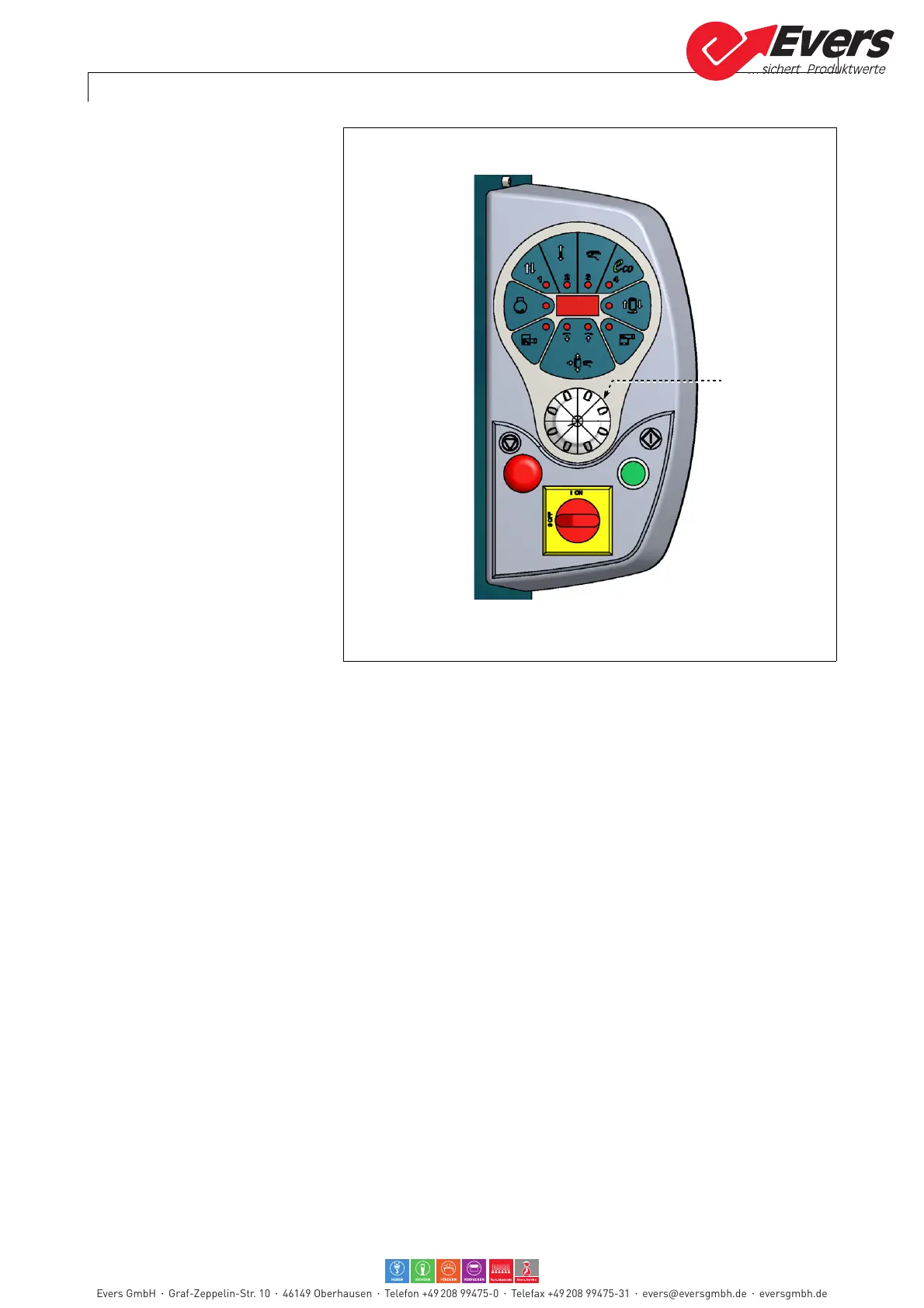

To view the production informa-

tion

1 -Activate main electric discon-

nector and press selector (D) at

the same time.

Message appears on the dis-

play.

–"d1" cycle partial counter

To reset, press selector for a

short period (about 3 seconds).

–"d2" cycle partial counter

(1000÷999000)

–"d3" cycle partial counter (0÷999)

–"d4" bootloader programme ver-

sion

–"d5" Voltage

–"d6" Sheet temperature

To programme the "Eco" wrap-

ping cycle

The "Eco" wrapping cycle can be

custom-made in order to optimise

and reduce any waste of time and

of packing material.

1 -Press selector and button "Cycle stop" at the same time.

Message "rEC" appears on the display.

The "Self-learning" mode is activated.

The system records all the operations to be performed in order to customise a

wrapping cycle (max 20 steps).

2- Press button "Start cycle".

The rotation of the rotary table and the movement of the reel holding carriage in

manual mode start at the same time.

3- Use selector in order to move the reel holding carriage.

4- When the reel holding carriage is brought to a "low" end of stroke position, press

button "Cycle stop" in order to complete the recording.

Rotary table stops in phase.

5- Press selector (D) and button "Cycle stop" at the same time in order to leave the

recording mode.

Press button "Cycle stop" in order to stop the cycle without bringing the reel

holding carriage to a "low" end of stroke position.

With this procedure, rotary table exceeds the point of phase, performs another

wrap and stops in phase.

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...