32

Reference Manual

00809-0100-4809, Rev DA

Section 2: Installation

September 2015

Installation

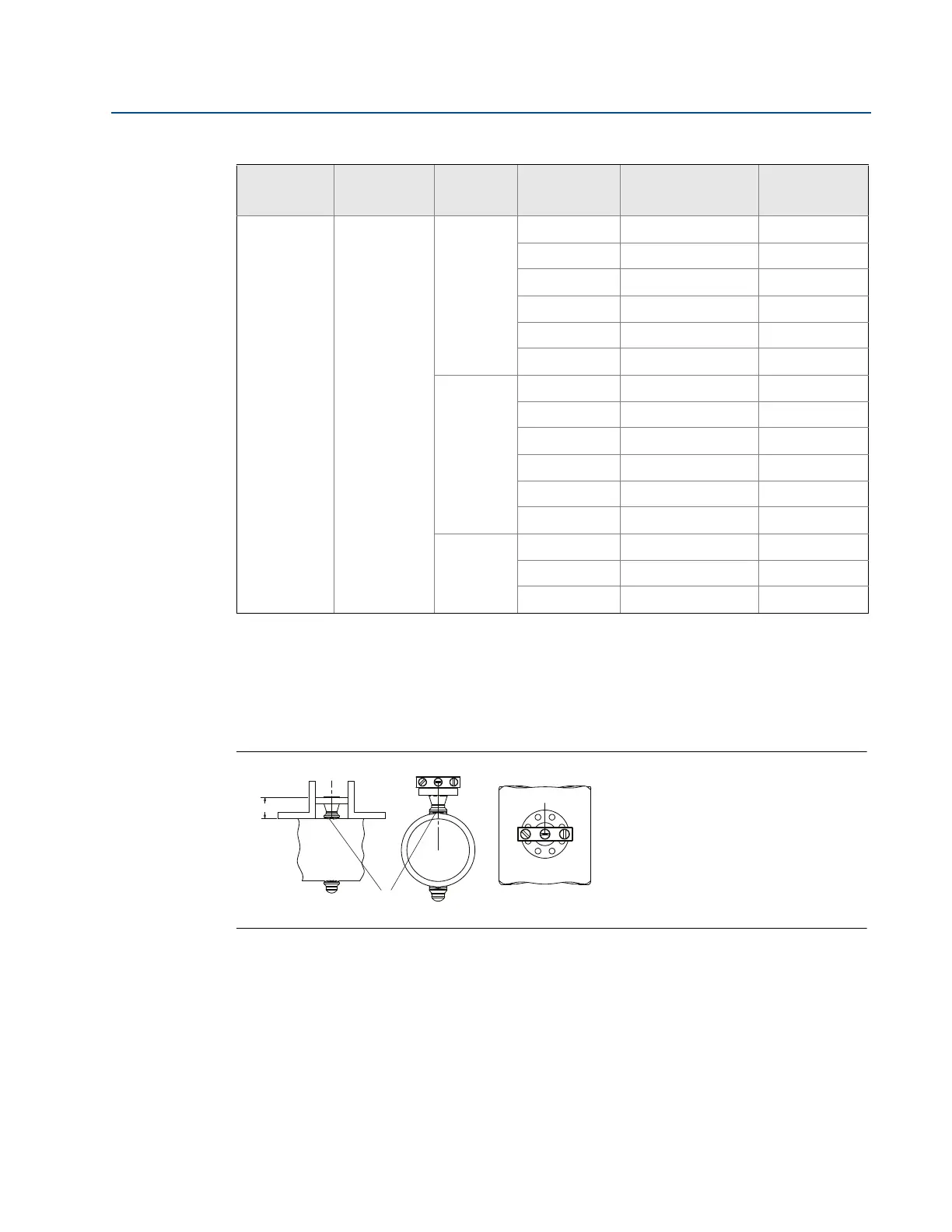

2. Place four

1

/4-in. (6-mm) tack welds at 90° increments. Check alignment of the

mounting both parallel and perpendicular to the axis of flow (see Figure 2-21). If

alignment of the mounting is within tolerances, finish weld per local codes. If alignment

is outside of specified tolerance, make adjustments prior to making the finish weld.

Figure 2-21. Alignment

A. Tack welds

3. Center the fitting for the opposite side support over the opposite side hole, gap

1

/16-in.

(1.5 mm) and place four

1

/4-in. (0.5 mm) tack welds at 90° increments. Insert the sensor

into the mounting hardware. Verify that the tip of the bar is centered in the opposite

side fitting and that the plug will fit around bar. If the sensor is centered in the fitting

and plug fits around the sensor, finish weld per local codes. If alignment of the sensor

does not allow enough clearance to insert the opposite side plug, make the necessary

adjustments prior to making the finish weld.

4. To avoid serious burns, allow the mounting hardware to cool before continuing.

3 44

A

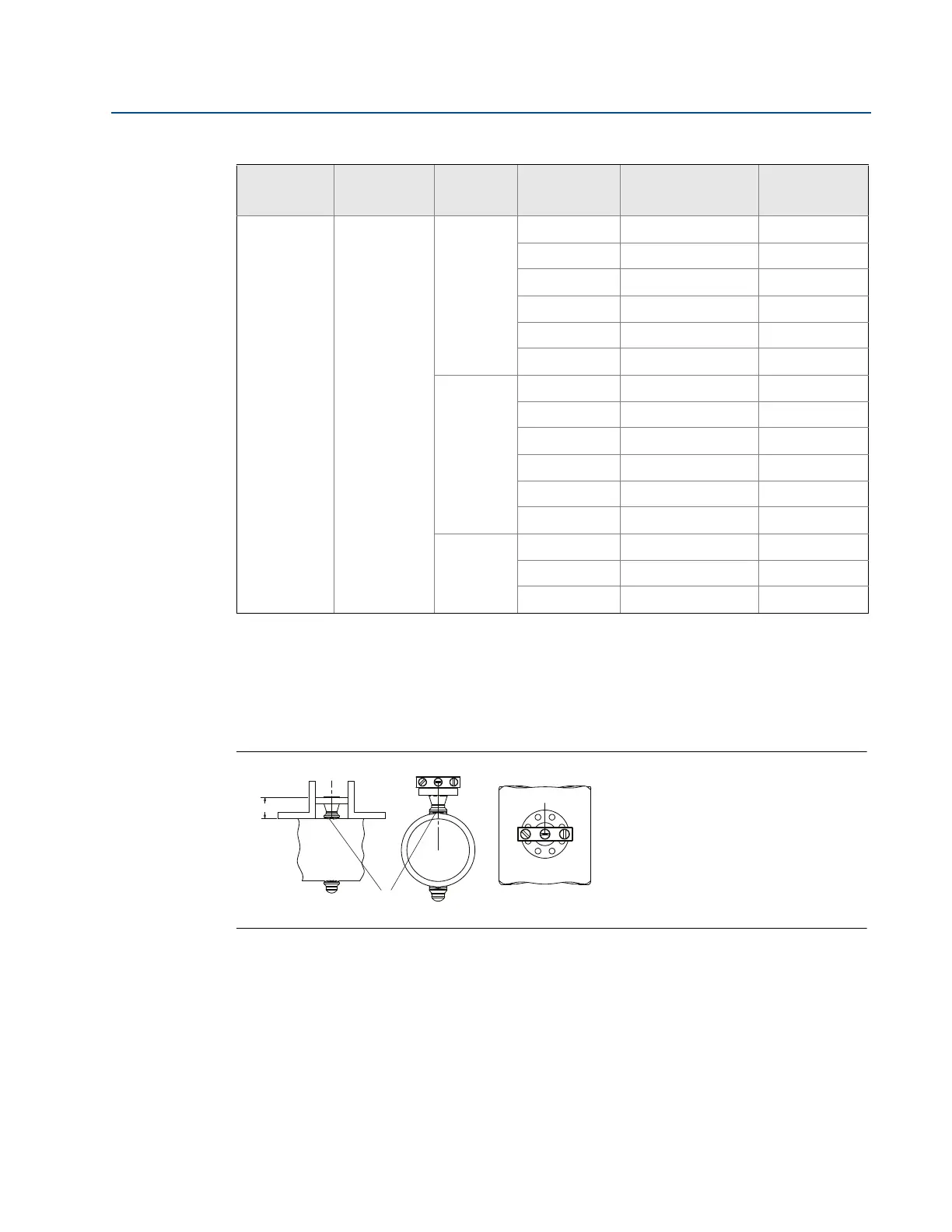

1 3.0-in. 150# RF 4.63 (117.6)

3 3.0-in. 300# RF 5.00 (127.0)

6 3.0-in. 600# RF 5.38 (136.7)

N/9 4.0-in. 900# RF 8.19 (208.0)

F 4.0-in. 1500# RF 8.56 (217.4)

T 4.0-in. 2500# RF 11.19 (284.2)

R

1 3.0-in. 150# RTJ 4.81 (122.2)

3 3.0-in. 300# RTJ 5.25 (133.4)

6 3.0-in. 600# RTJ 5.44 (138.2)

N/9 4.0-in. 900# RTJ 8.25 (209.6)

F 4.0-in. 1500# RTJ 8.63 (219.2)

T 4.0-in. 2500# RTJ 11.38 (289.1)

D

1 DN80 PN16 RF 3.85 (97.8)

3 DN80 PN40 RF 4.16 (105.7)

6 DN80 PN100 RF 4.95 (125.7)

1. Tolerances for the ODF dimension above a 10-in. (254 mm) line size is ±0.060-in. (1,6 mm). Below 10-in. (254 mm) line size is

±0.030-in. (0,8 mm).

Table 2-6. 485 and 585 Flange Sizes and ODF per Sensor Size

485 Sensor

size

585 Sensor

size

Flange

type

Pressure

class

Flange size/

rating/type

ODF in.

(mm)

(1)

ODF

A

Loading...

Loading...