39

Reference Manual

00809-0100-4809, Rev DA

Section 2: Installation

September 2015

Installation

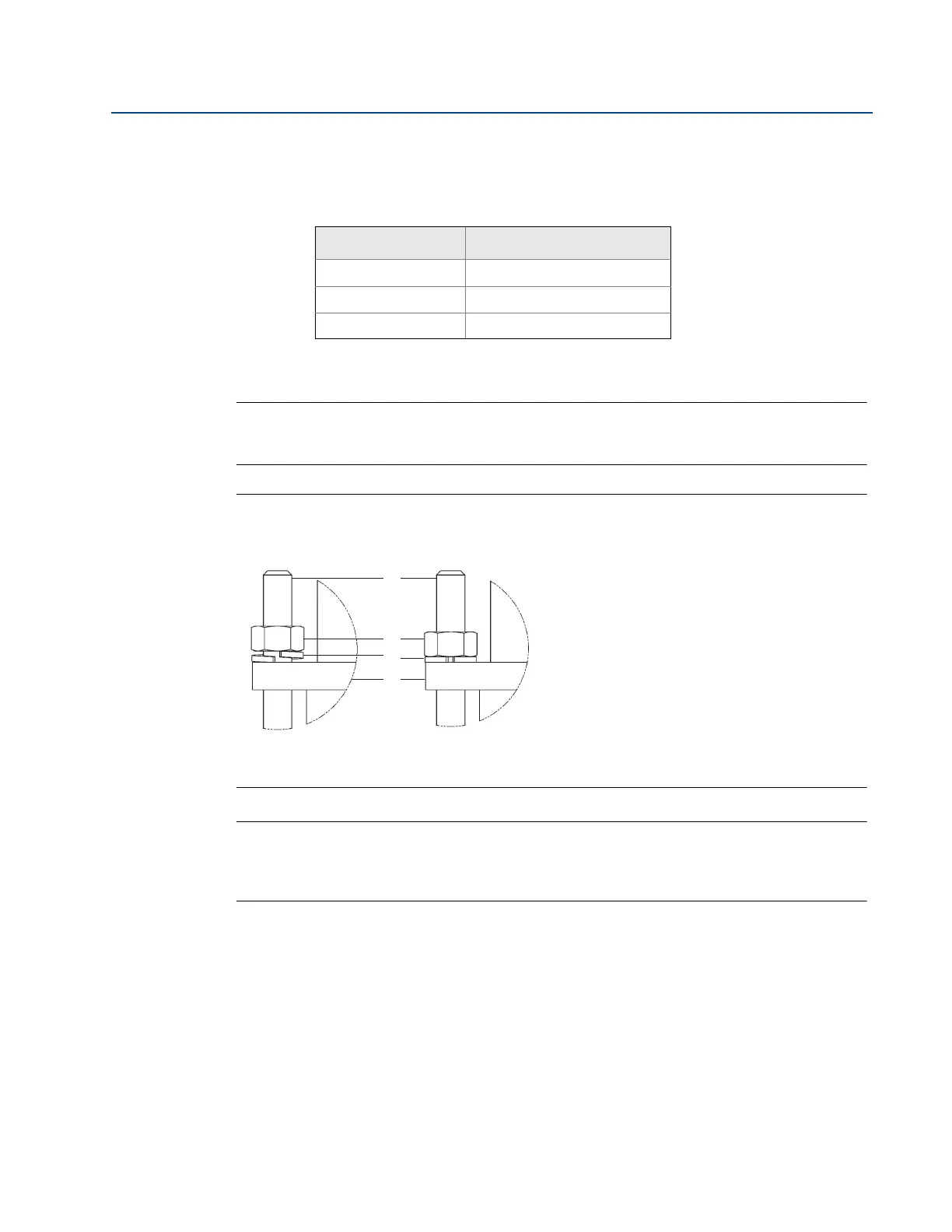

11. Tighten the nuts onto the studs:

a. Place the included split-ring lock washer between each of the nuts and the

compression plate. Give each nut one half (

1

/2) turn in succession until the split-ring

lock washer is flat between the nut and the compression plate. Torque is as follows:

b. Inspect the unit for leakage; if any exists, tighten the nuts in one-quarter (

1

/4) turn

increments until there is no leakage.

Note

On sensor size (1), failure to use the split-ring Lock washers, improper washer orientation, or

over-tightening the nuts may result in damage to the flowmeter.

Figure 2-25. Split-Ring Lock Washer Orientation

Note

Flange-Lok sealing mechanisms generate significant force at the point where the sensor

contacts the opposite pipe wall. Caution needs to be exercised on thin-walled piping (ANSI

Schedule 10 and below) to avoid damage to the pipe.

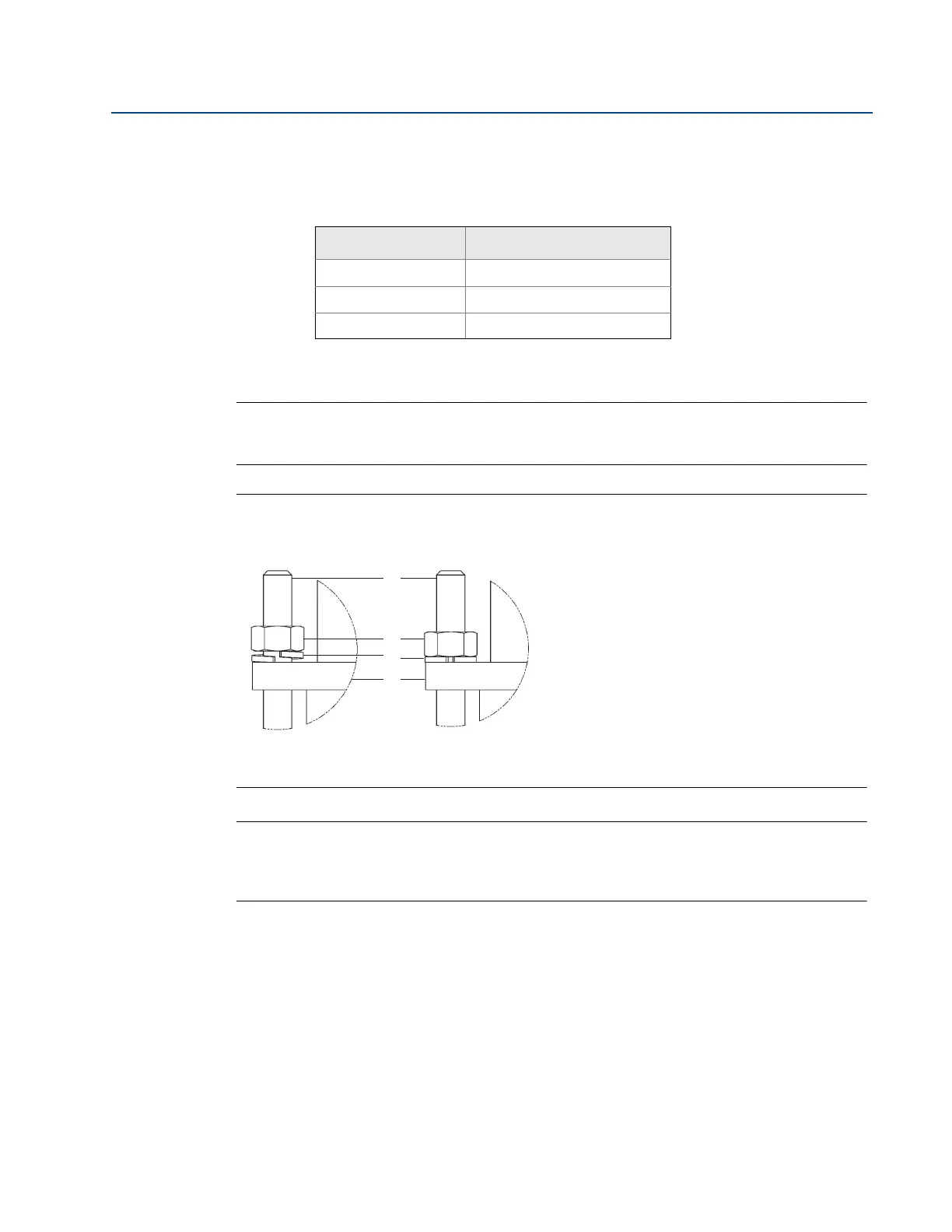

Sensor size Torque

1 40 in/lb (4.52 Nm)

2 100 in/lb (11.30 Nm)

3 250 in/lb (28.25 Nm)

Before tightening After tightening

A. Stud

B. Nut

C. Split ring lock washer

D. Compression plate

A

B

C

D

Loading...

Loading...