64

Reference Manual

00809-0100-4809, Rev DA

Section 3: Commissioning

September 2015

Commissioning

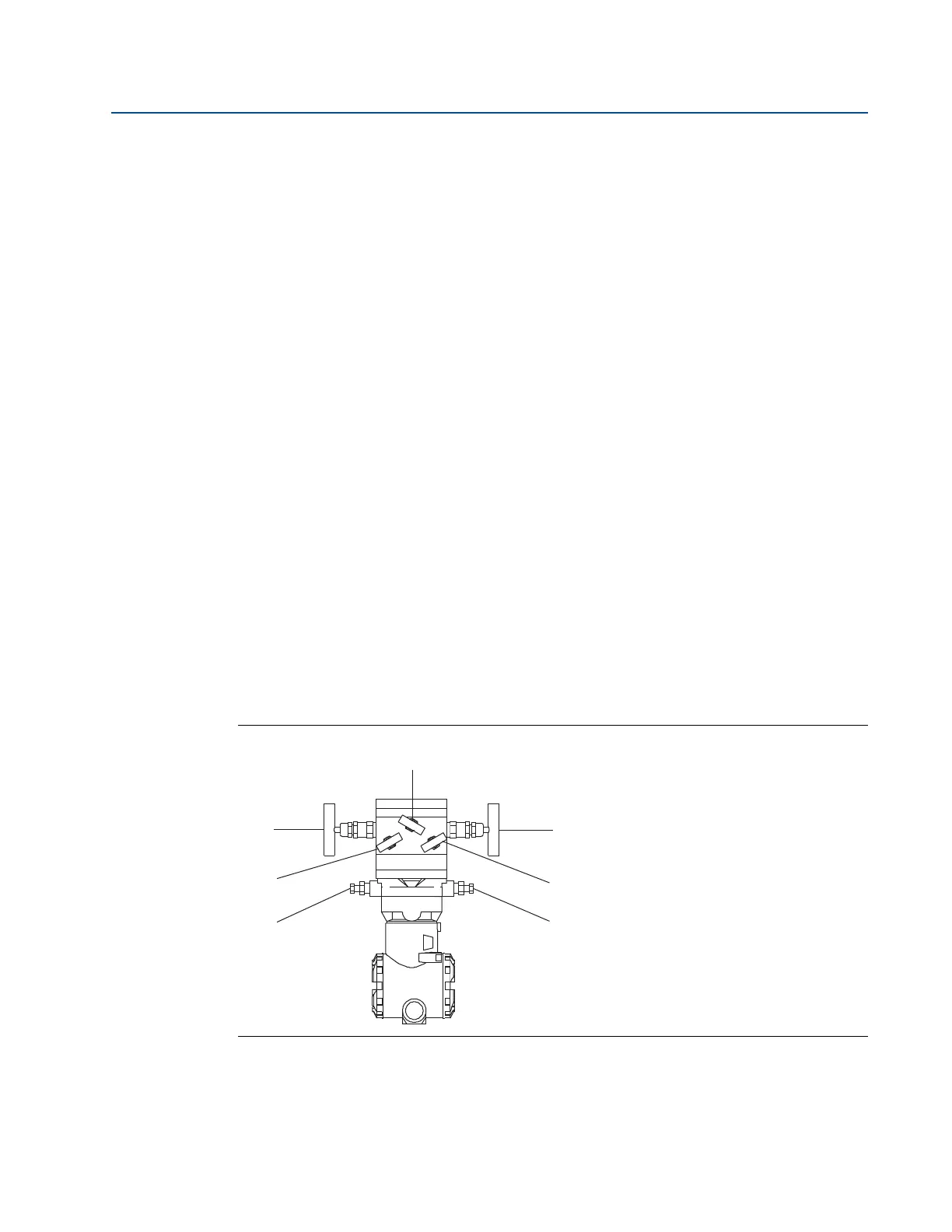

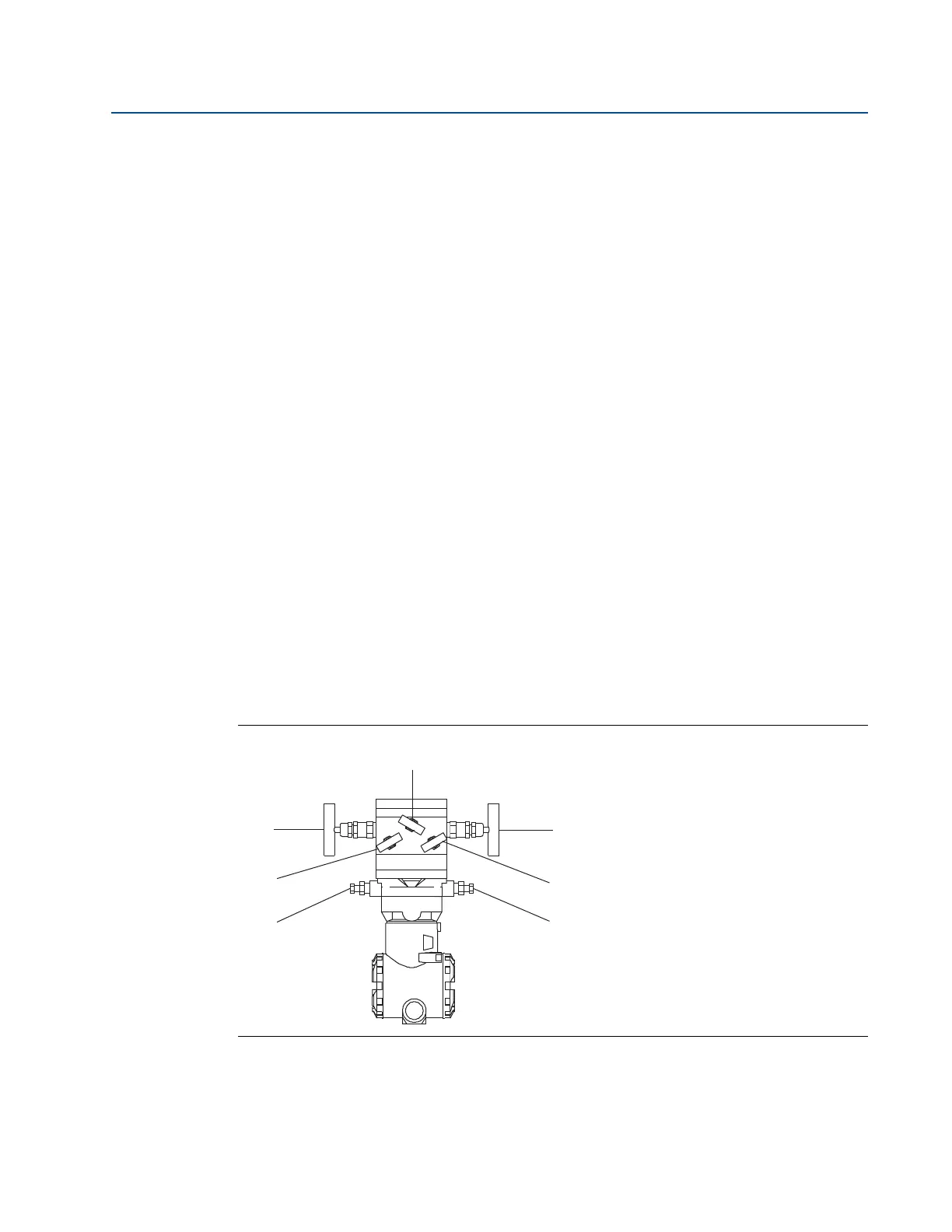

Liquid service 5-valve manifold

The following procedures assume the process pipe is pressurized to normal operating pressure

and should be followed to obtain a true zero at static or “pipe” pressure.

1. Open high and low manifold valves MH and ML. Refer to Figure 3-2 for valve

designations.

2. Open high side equalizer valve MEH.

3. Open low side equalizer valve MEL.

4. Open manifold vent MV; Bleed until no air is present in the liquid.

5. Close manifold vent MV.

6. Close low side manifold valve ML.

7. Check transmitter zero by noting the output. If the signal reads outside of the range

3.98 mA to 4.02 mA then perform a zero trim procedure as described in the transmitter

manual.

8. After the zero trim, if the signal reads outside the range 3.98 mA to 4.02 mA, repeat

Steps 1 - 6.

9. Close low side equalizer valve MEL.

10. Close high side equalizer valve MEH.

11. Open low side manifold valve ML and ensure high side manifold valve MEH is open.

12. The system is now operational.

Figure 3-2. Valve Identification for Direct Mounted Models with 5-Valve Manifold

Loading...

Loading...