B-3

Appendix B

Process Conditions Process conditions and loop elements must be considered during site

selection to ensure an accurate, noise-free output signal. Avoid

placement near pumps (especially positive displacement pumps) or flow

variations may appear in the output signal.

Also, keep slurries as homogeneous as possible to prevent damage to

the flowtube electrodes and liner. Homogeneity can often be achieved by

locating the flowtube five straight pipe diameters downstream of loop

pumps, with additives upstream of the pumps.

Finally, design the process loop conditions to ensure that the flowtube

always remains full, with no entrapped air.

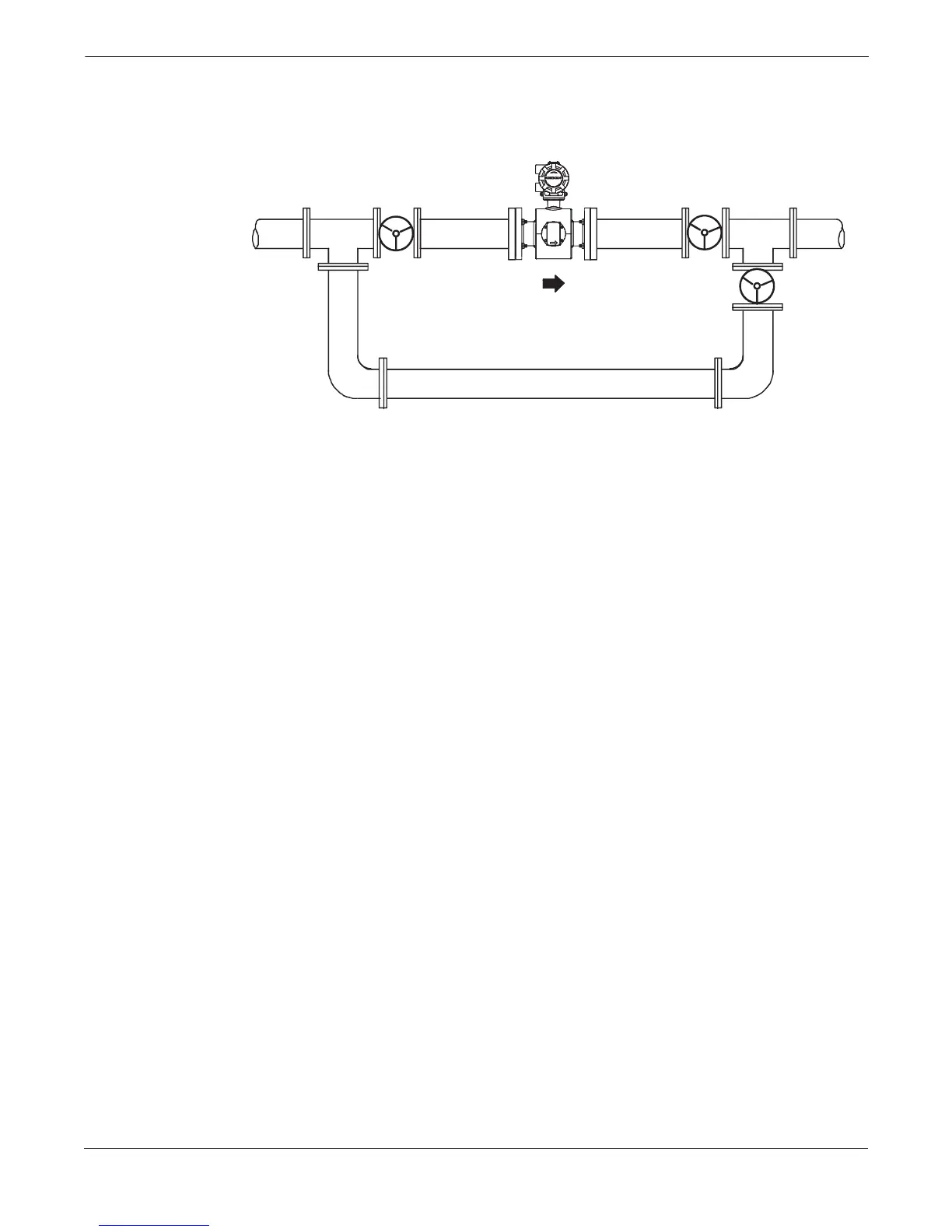

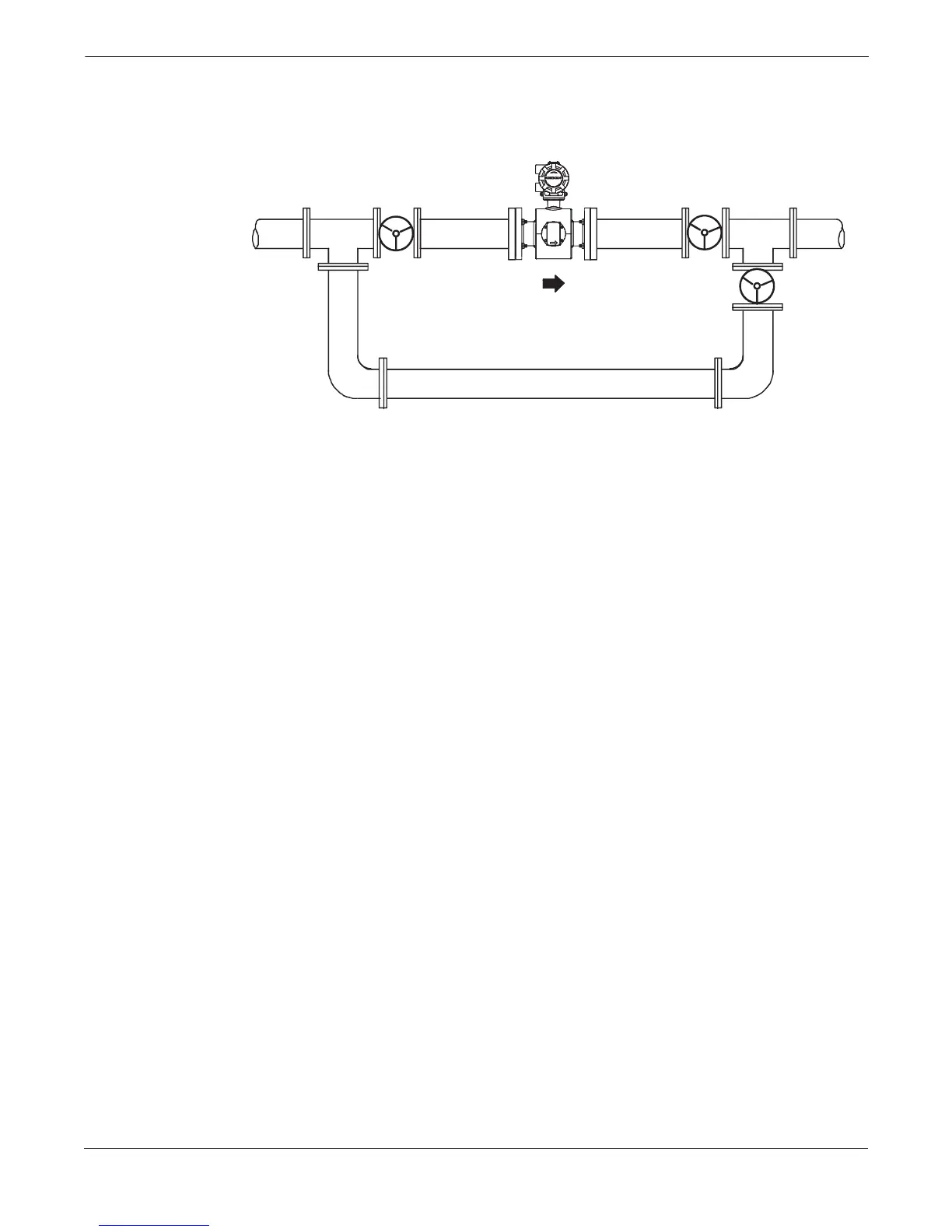

Adequate Space Allow space for the flowtube, bypass piping, and equipment

maneuverability during installation and removal. Note that integrally

mounted transmitters require more space at the flowtube site.

Earth Ground Specification accuracy and safety considerations require

flowtube grounding.

Low-Noise Environment Although a pulsed dc coil design reduces flowtube susceptibility to

extraneous noise, some environments are more suitable than others.

Avoid a close proximity to devices that may produce high intensity

electromagnetic and electrostatic fields. Such devices include electric

welding equipment, large electric motors and transformers, motor

devices or controls, and communication transmitters.

Conductivity Process fluid conductivity should be 5 microsiemens/cm (5 micromhos/

cm) or greater. For low conductivity fluids, 5–20 micromhos/cm, cable

length should be less than 25 feet and unshielded cable ends should

be maintained.

8732-0044C

Flow

FIGURE B-2.

Typical Bypass Piping Configuration.

Loading...

Loading...