Rosemount Model 8732C Integral Mount Magnetic Flowmeter System

2-12

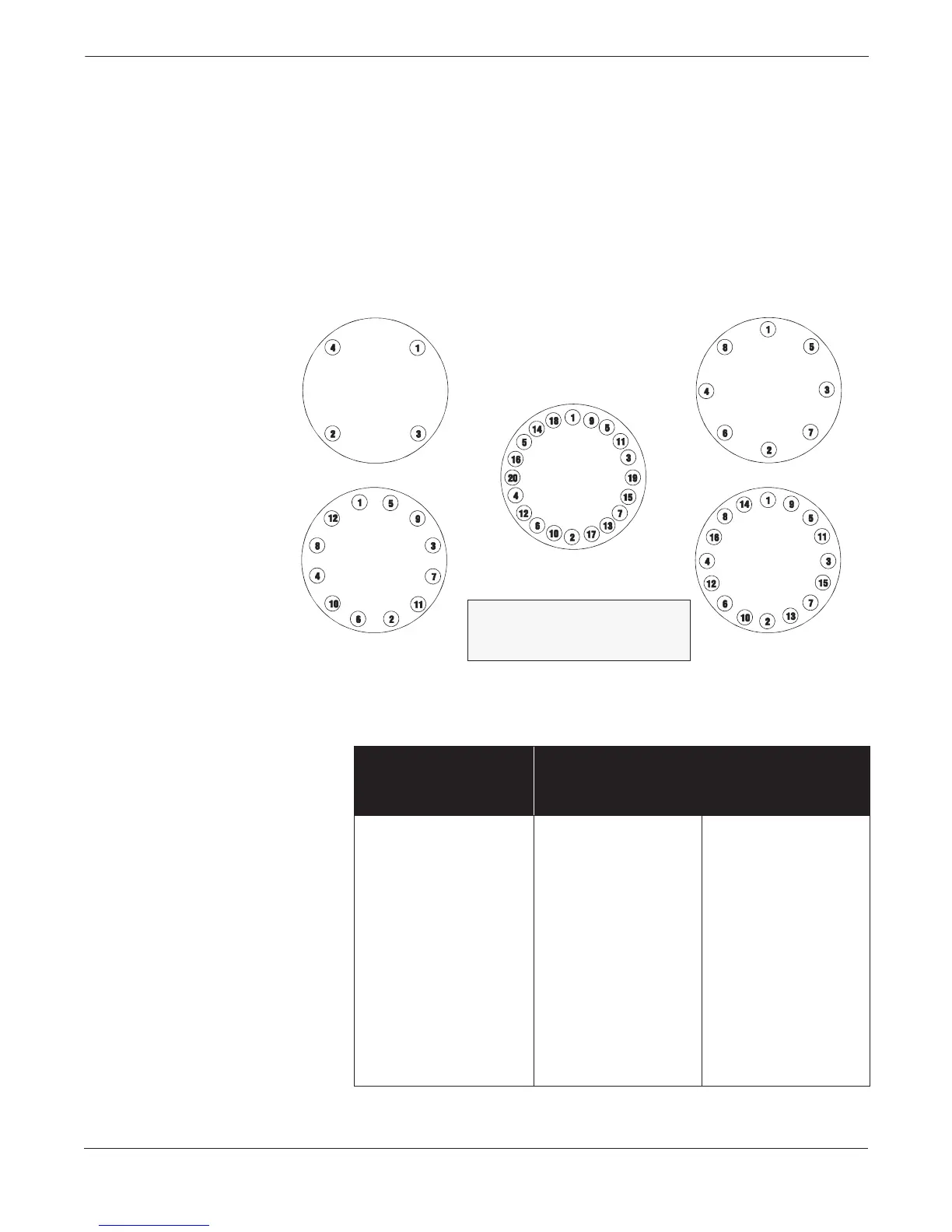

Flange Bolts

Flowtube sizes and torque values for Class 150 and Class 300 flanges

are listed in Table 2-3. Tighten flange bolts in the incremental sequence

shown in Figure 2-11.

Model 8705 Correct flange bolt tightening is crucial for proper flowtube operation and

life. All bolts must be tightened in the proper sequence to the specified

torque limits. Failure to observe these instructions could result in severe

damage to the flowtube lining and possible flowtube replacement.

Always check for leaks after tightening flange bolts. All flowtubes

require a second torquing 24 hours after initial flange bolt tightening.

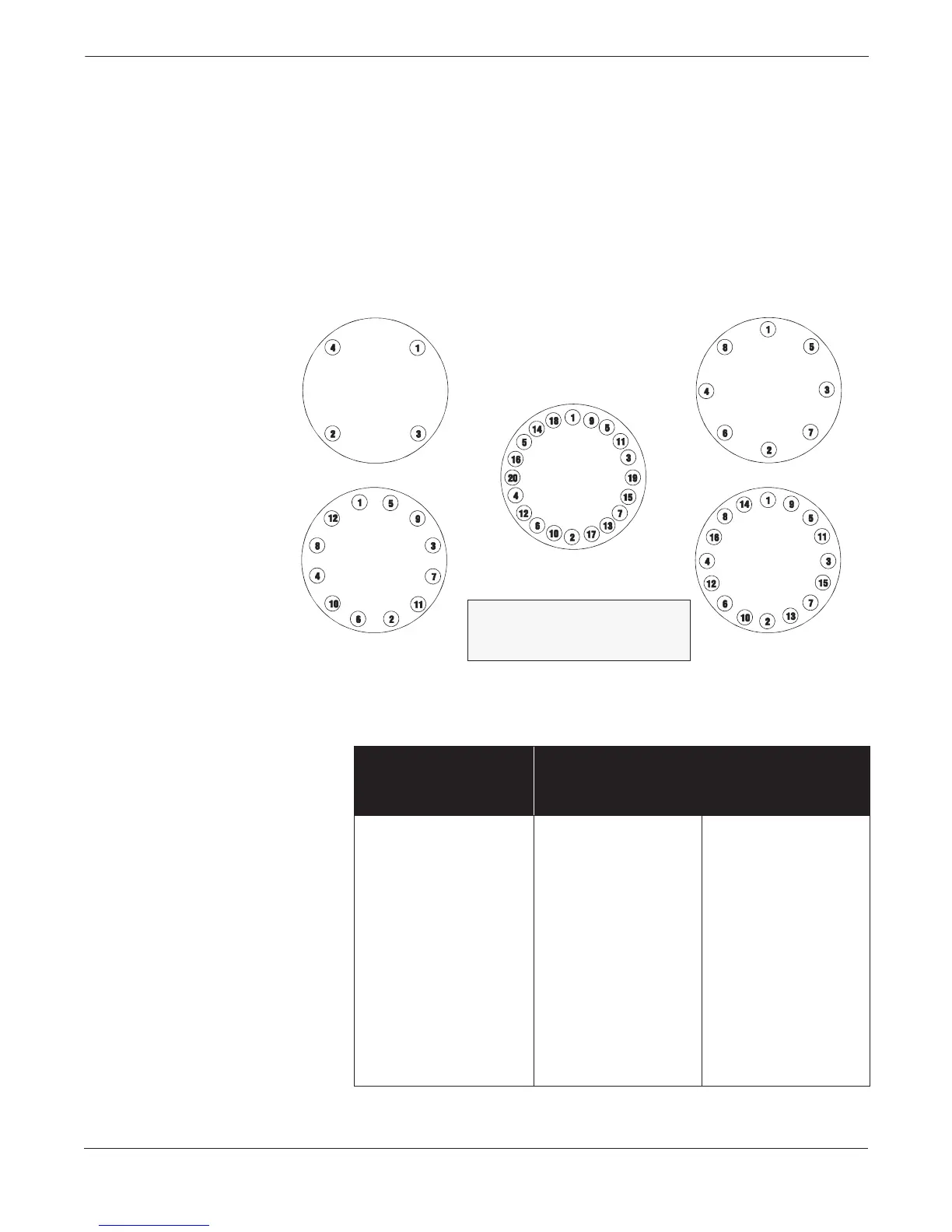

TABLE 2-3. Model 8705 Flange Bolt

Torque Specifications.

Torque the flange bolts

in increments according to

the above numerical sequence.

8701-0589A

4-Bolt

8-Bolt

12-Bolt

14-Bolt

20-Bolt

FIGURE 2-11. Model 8705 Flange

Bolt Torquing Sequence.

Nominal

Flowtube

Size (inches)

Flange Bolt Torque

Specifications in Foot-Pounds

Class 150 Flange Class 300 Flange

½

1

1½

2

3

4

6

8

10

12

14

16

18

20

24

30

36

10

10

17

25

45

35

60

80

70

80

100

90

125

125

150

150

200

10

10

22

17

35

50

65

60

65

80

—

—

—

—

—

—

—

Loading...

Loading...