Reference Manual

00809-0100-4004, Rev BA

August 2010

Rosemount 8800D

2-10

1. Place the alignment rings over each end of the meter body.

2. Insert the studs for the bottom side of the meter body between

the pipe flanges.

3. Place the meter body (with alignment rings) between the

flanges. Make sure that the alignment rings are properly

placed onto the studs. Align the studs with the markings

on the ring that correspond to the flange you are using.

If a spacer is used, see Spacers and Table 2-6 below.

NOTE

Be sure to align the flowmeter so the electronics are accessible, the

conduits drain and the flowmeter is not subject to direct heat.

4. Place the remaining studs between the pipe flanges.

5. Tighten the nuts in the sequence shown in Figure 2-9 on page 2-13.

6. Check for leaks at the flanges after tightening the flange bolts.

NOTES

The required bolt load for sealing the gasket joint is affected by several

factors, including operating pressure and gasket material, width, and

condition. A number of factors also affect the actual bolt load resulting from a

measured torque, including condition of bolt threads, friction between the nut

head and the flange, and parallelism of the flanges. Due to these

application-dependent factors, the required torque for each application may

be different. Follow the guidelines outlined in the ASME Pressure Vessel

Code (Section VIII, Division 2) for proper bolt tightening.

Make sure the flowmeter is centered between flanges of the same

nominal size as the flowmeter.

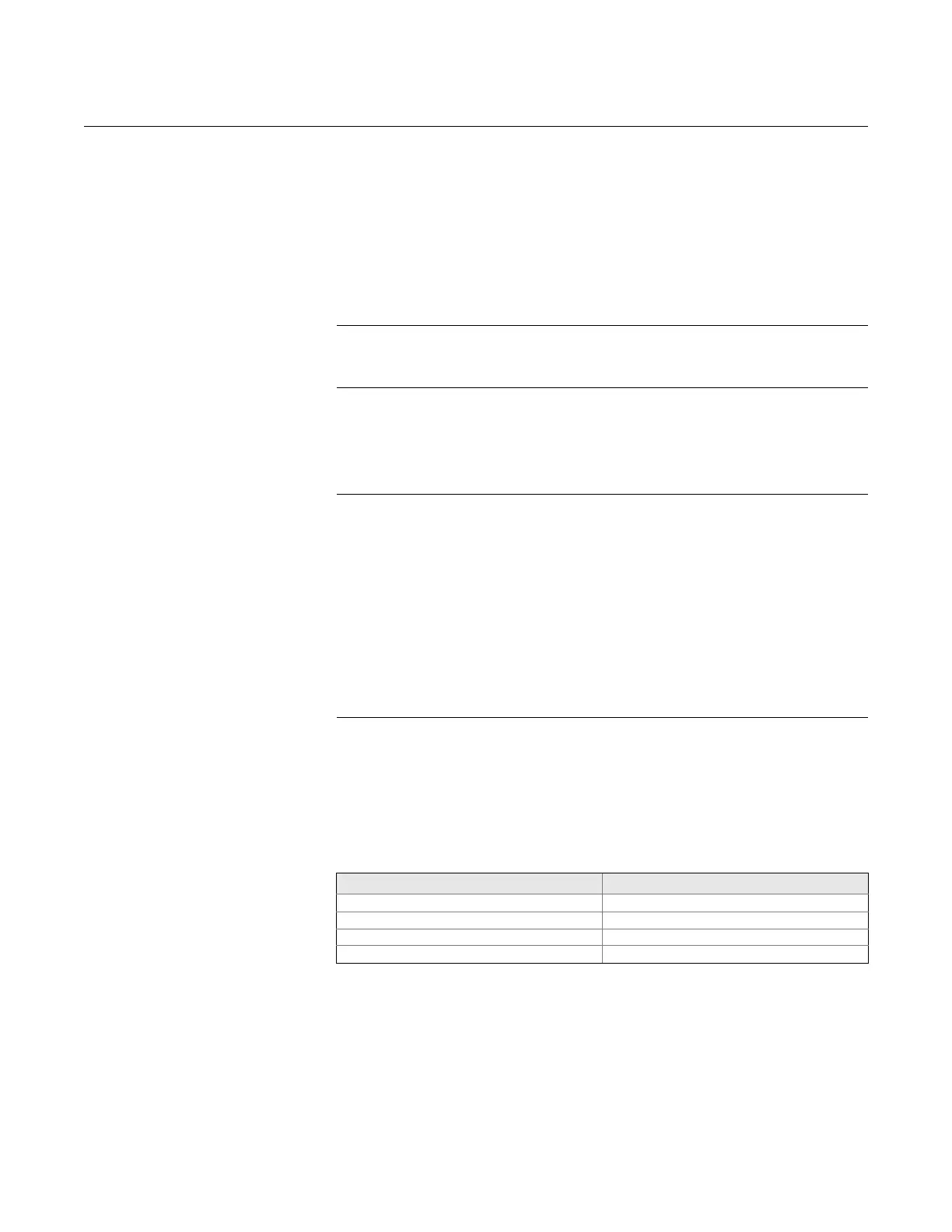

Spacers

Spacers are available with the Rosemount 8800D to maintain the

Rosemount 8800A dimensions. If a spacer is used, it should be downstream

of the meter body. The spacer kit comes with an alignment ring for ease of

installation. Gaskets should be placed on each side of the spacer.

Table 2-6. Dimensions for Spacers

Line Size Dimensions inch (mm)

1.5 (40) 0.47 (11.9)

2 (50) 1.17 (29.7)

3 (80) 1.27 (32.3)

4 (100) 0.97 (24.6)

Loading...

Loading...