Operating instructions for actuators type AB with SMARTCON control unit

OM-ENGLISH-CSC-V2.08-2019.11.07 15 Training

Example:

Extremely low OP + extremely low ambient temperature + high revolution + utilization factor 87%

⇒0.8 x 0.9 x 0.8 x 0.9 = 0.51 reduction factor.

Lubricant maintenance interval ⇒ 10 years x 0.51 = 5.1 years (62 months).

WARNING: A thusly calculated maintenance interval does not apply to the maintenance of the out-

put type A (threaded bushing), nor to the maintenance of the linear and spindle actuator units. These

must be regularly re-greased (at least once every six months) at the lubricating nipples (see section

14.3, page 48)!

During actuator maintenance, the old lubricants must be thoroughly removed and replaced by fresh ones.

No mixing of different makes of lubricant is permitted!

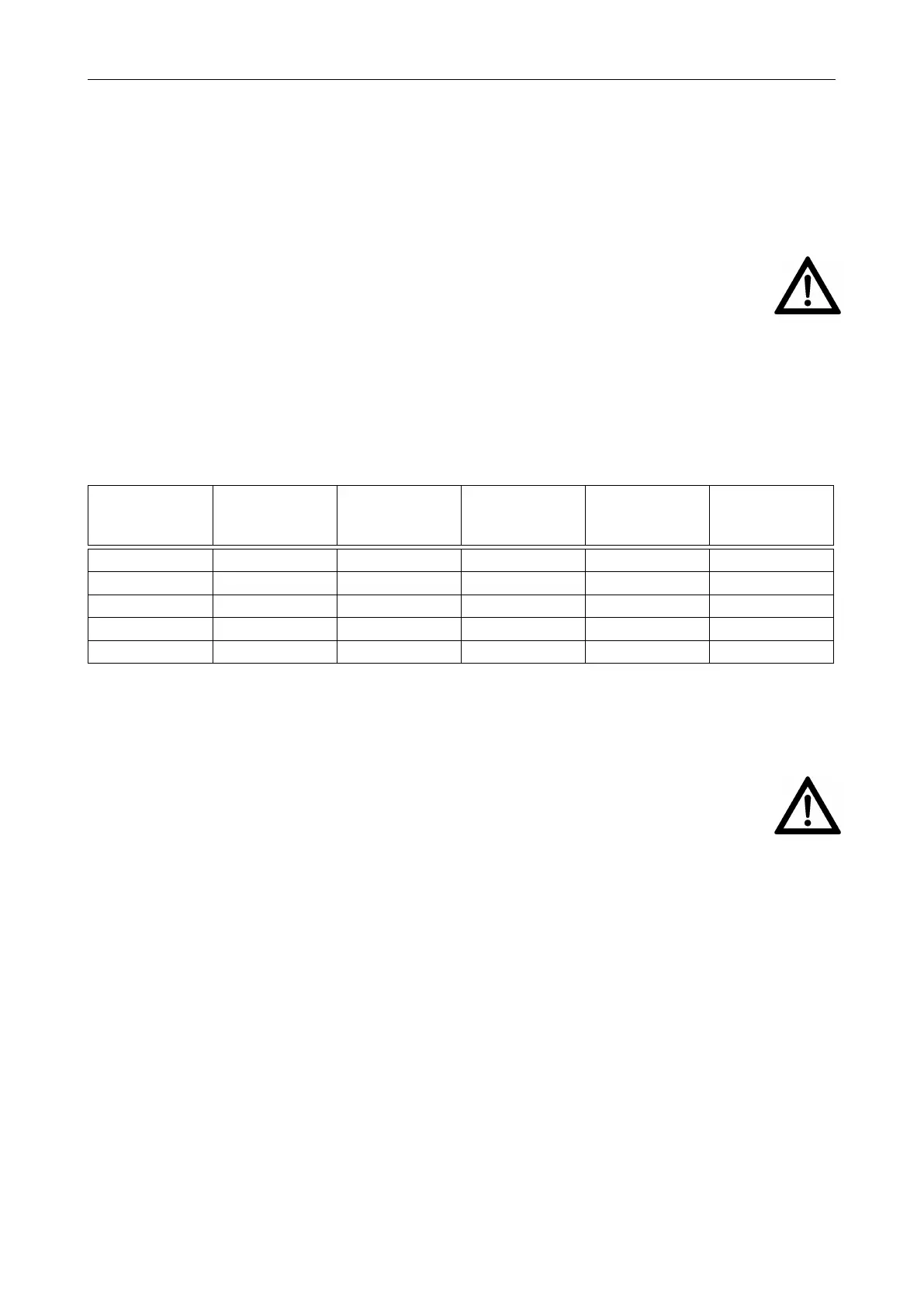

The quantities needed for lubricant service can be seen from the table below.

14.6 Lubricant Requirements

Type of actuator Main gear Spur gears

Output form A

(Threaded

bushing)

Output form B

(Plug bushing)

Output form C

(Claw coupling)

AB3/5 1kg (1l oil) — 5cm

3

3cm

3

3cm

3

AB8 1kg (1l oil) 1cm

3

5cm

3

3cm

3

3cm

3

AB18 1kg (1l oil) 1cm

3

8cm

3

5cm

3

5cm

3

AB40/80 1,5kg (1,5l oil) 1,5cm

3

9cm

3

6cm

3

6cm

3

AB100/200 3,5kg (3,5l oil) 1,5 kg (1,5l oil) 23cm

3

20cm

3

20cm

3

When lubricating precision components, such quantities of lubricant are to be used as to ensure fine moistening

of the sliding surfaces.

15 Training

Warning: Should problems arise on site in connection with assembly or adjustment, please contact

the SCHIEBEL Antriebstechnik Gesellschaft m.b.H, Josef-Benc Gasse 4, A-1230 Vienna,

Telephone +43 (1) 66 108 or by internet http://actuators.schiebel.com, in order to avoid any incorrect

operations or damage to the actuators. The Schiebel Company recommends to recruit only qualified personnel

for assembly of Schiebel actuators. Upon special request by the ordering party, personnel can be trained on

the premises of the Schiebel Company according to the operations listed in the instructions for use.

49

Loading...

Loading...