5 Commisioning

Operating instructions for actuators type AB with SMARTCON control unit

OM-ENGLISH-CSC-V2.08-2019.11.07

5 Commisioning

Before commissioning, please ensure the actuator is correctly assembled and electrically connected. (see

section 4, page 9)

CAUTION: Remove silica gel from the connection compartment

5.1 General

textbfCAUTION: During commissioning and after every disassembly of the actuator, you have to

make the mechanical preadjustment (see sction 5.3, page 13), adjust the mechanical position indi-

cation (see section 5.4, page 14), adjust the additional components (see scetion 5.5, page 14) and

adjust the end positions (see section 5.7, page 14).

ATTENTION: The torque unit is adjusted at work and must not be changed.

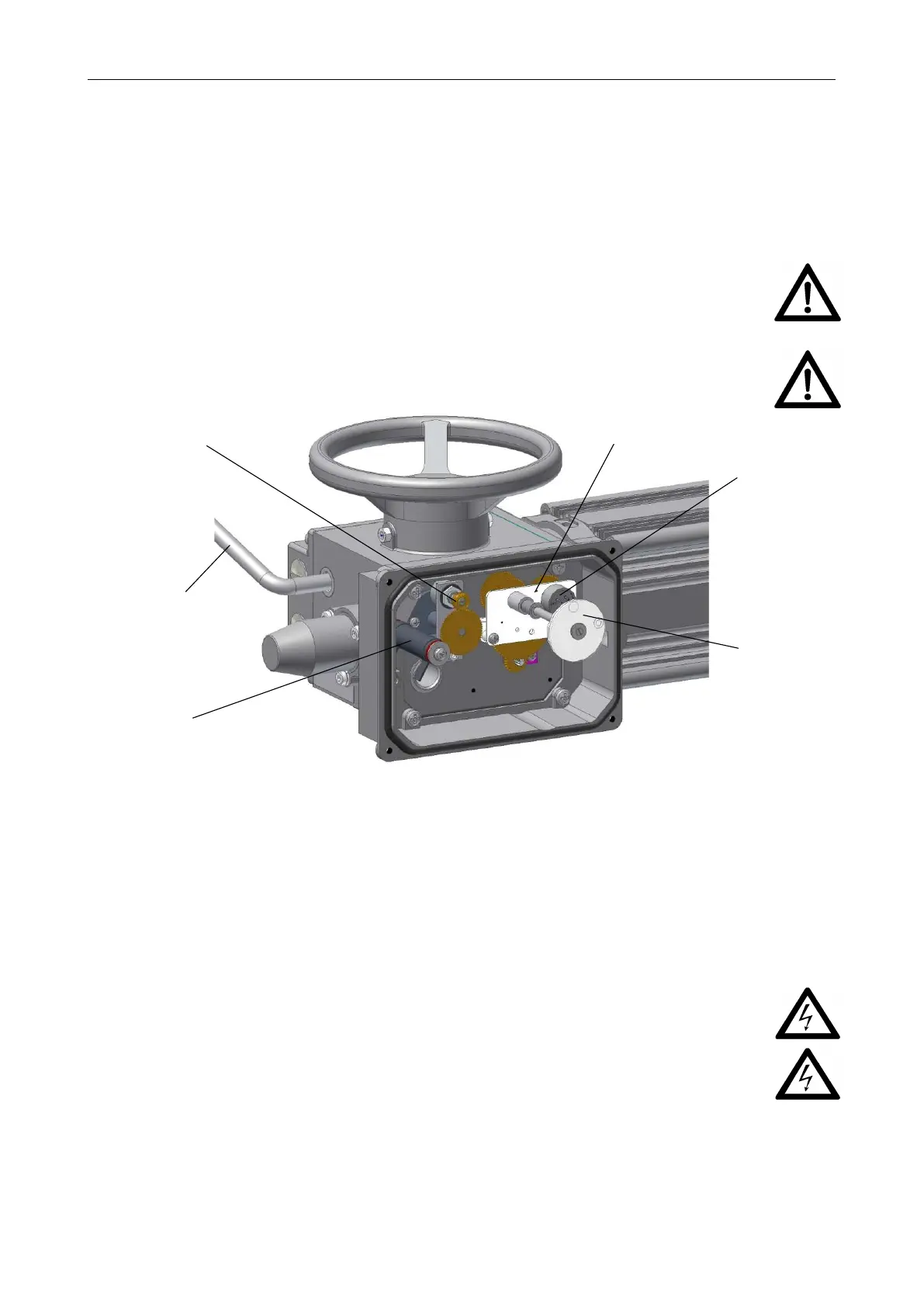

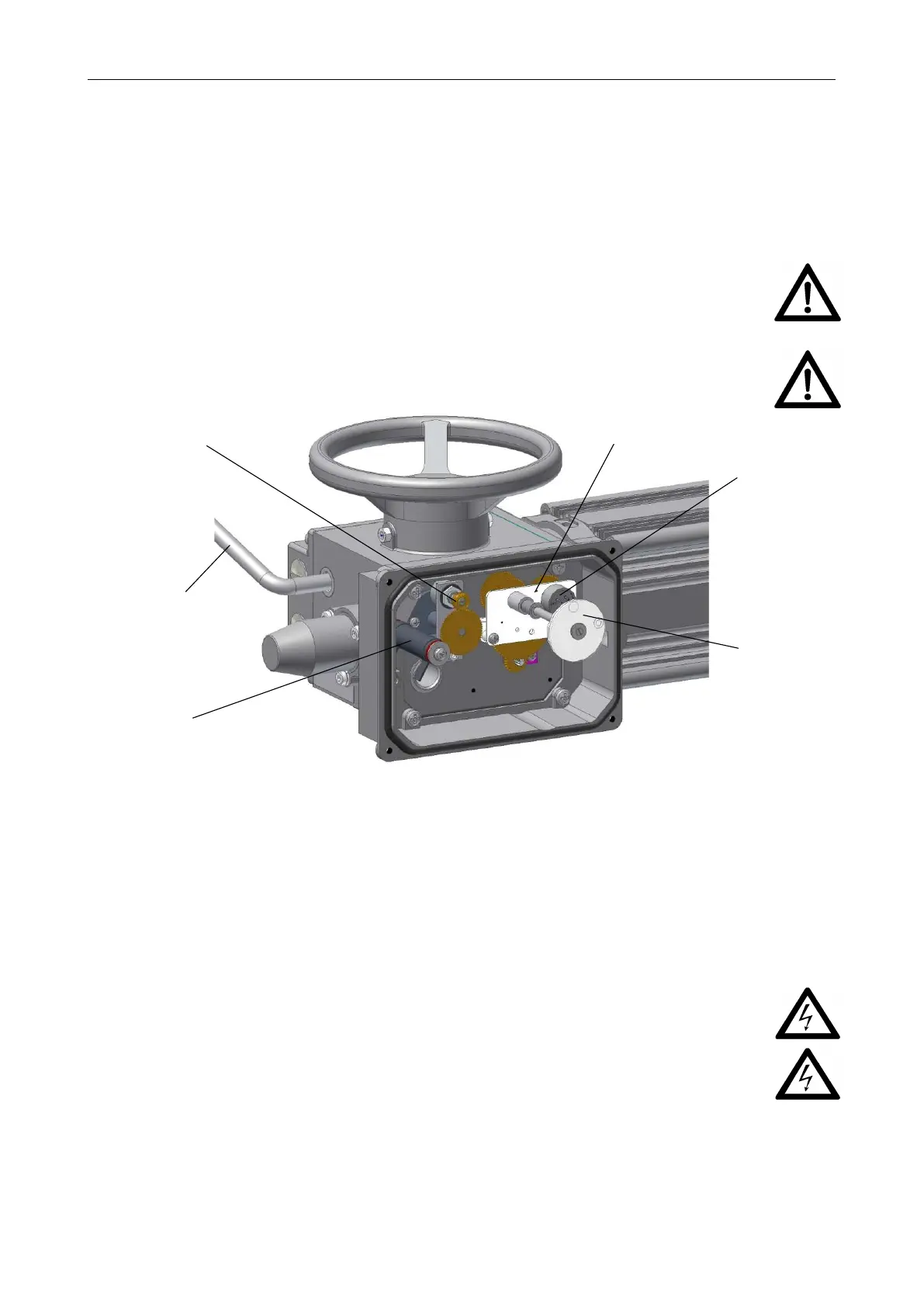

Figure 14: 1. . . torque unit , 2. . . hand lever, 3. . . heating resistor - Attention: HOT!!!, 4. . . gearing of travel

unit, 5. . . potentiometer for travel sensing, 6. . . mech. position indicator (option)

5.2 Switching the actuator to manual operation

The actuator is switched to manual operation by moving the hand lever (see Figure 15 u. 16) by approximately

15

◦

, and by simultaneously turning the hand wheel. The lever remains in this position and will be switched

back automatically as the motor starts up.

WARNING:

•

When switching to manual operation, the actuator’s automatic interlock is deactivated, that

means that the driven valve must not initiate reverse torque to the output shaft of the actuator!

•

Switching back to motor operation is made automatically as the motor starts up. It must not

be undertaken with the hand lever!

• Only switch to manual operation when the motor is idle!

• Hand lever has a slewing angle of approximately 15

◦

, therefore release the hand lever immediately

upon activation!

Labels on the actuator:

12

Loading...

Loading...