Page 68

STAT

IM

2000/2000S Service Guide

96-106775 Rev 5.0

3. Troubleshooting Cycle Faults

STATIM 5000/5000S/5000 G4 Service Guide

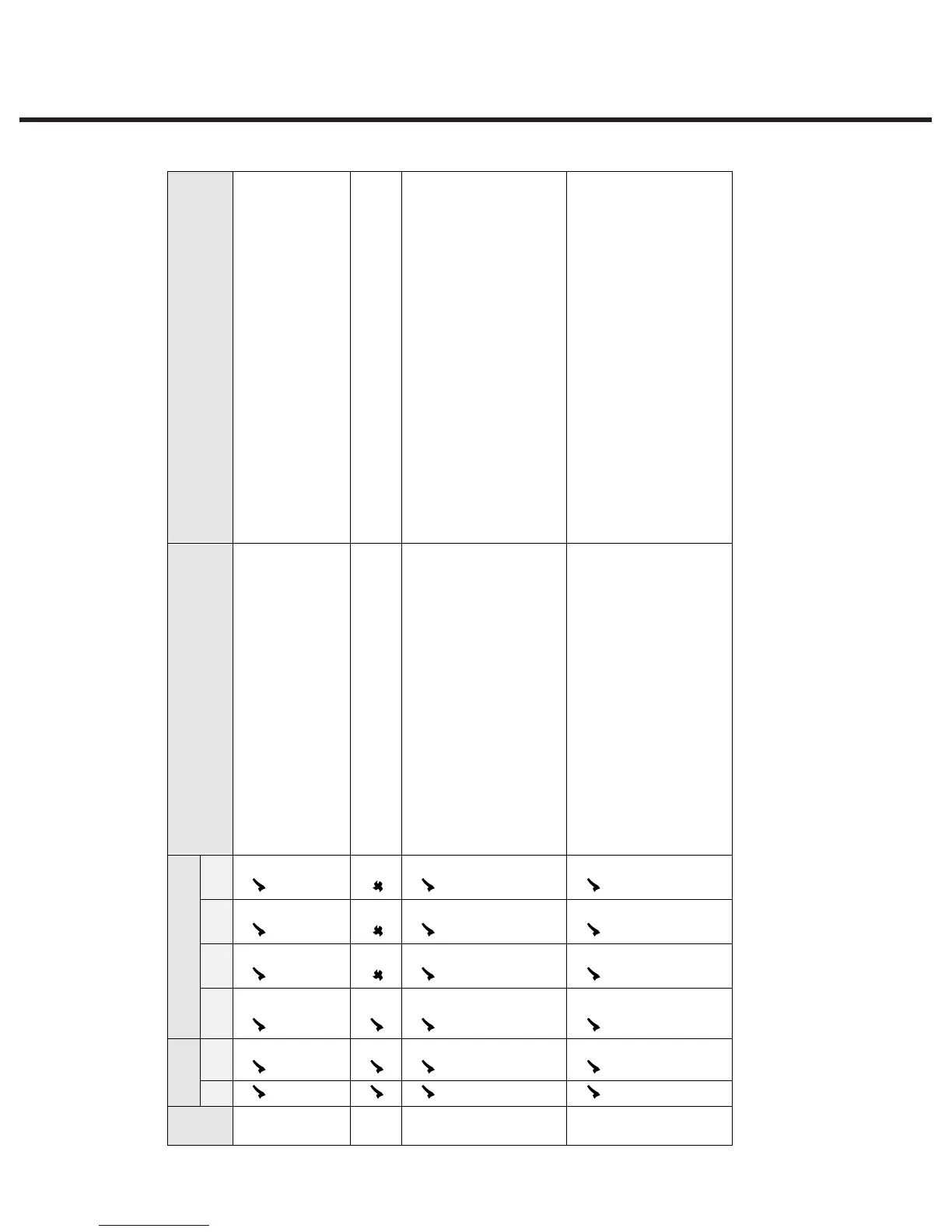

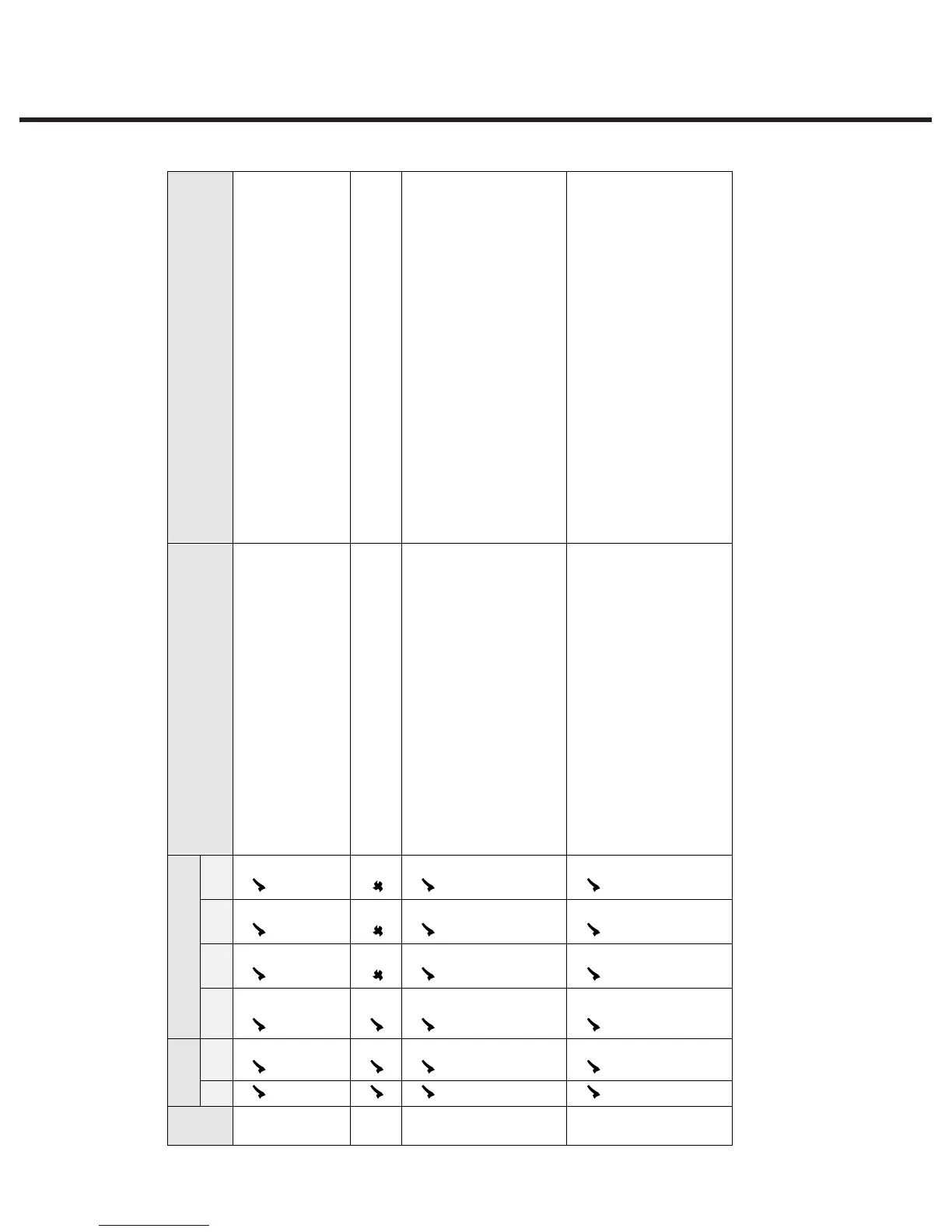

No.

Description of Fault

Probable Cause (or causes) of Fault

S Non

1.xx/

4.xx 5.xx 6.xx

1

The cassette temperature failed to reach 95ºC

within a time-out period.

• Large cassette leak

• Overloaded cassette

• Poor pump delivery

• Blown thermal fuses

• Contaminated steam generator

• Failed steam generator triac

• Steam generator fault (open circuit).

2

The cassette temperature failed to increase from

95°C to 100°C within a time-out period.

• Major steam leak

• Overloaded cassette

•

Incorrect chamber calibration

3

The cassette has failed to pressurize and

achieve a temperature of 110ºC within a time-

out period.

This may be caused by a

• Faulty cassette seal

• Damaged cassette

• Steam circuit leak (tubing)

• Incorrect probe alignment

• Sticking solenoid valve (open)

• Check valve leak

• PRV leak

Check Vref is 2.520V± 0.001V (all software revisions

OTHER THAN revision 6.xx)

4

The cassette has failed to achieve sterilization

conditions within a timeout period.

• Faulty cassette seal

• Damaged cassette

• Steam circuit leak (tubing)

• Incorrect probe alignment

• Sticking solenoid valve (open)

• Check valve leak

• PRV leak

Check Vref is 2.520V± 0.001V (all software revisions

OTHER THAN revision 6.xx)

Loading...

Loading...