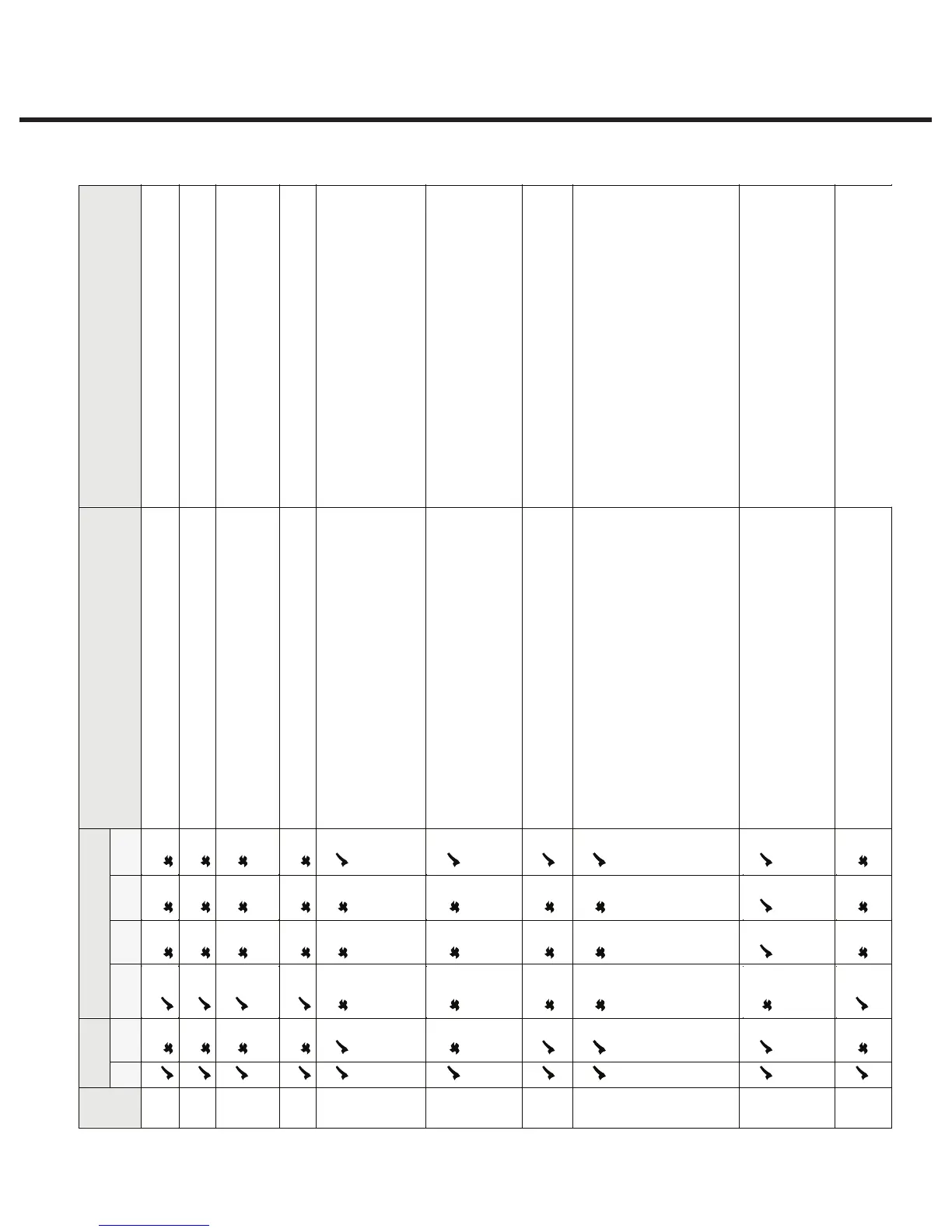

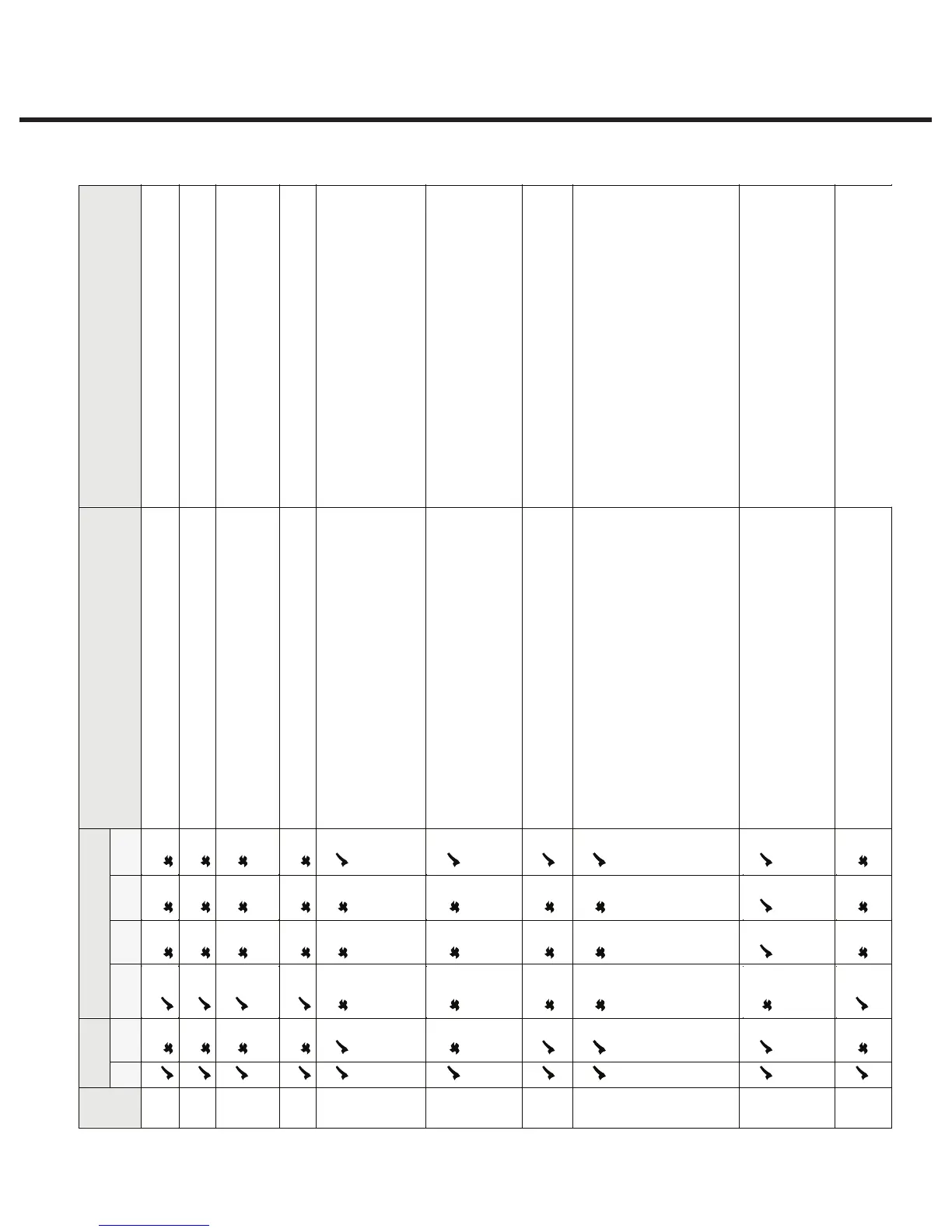

3. Troubleshooting Cycle Faults

CF

No.

Unit

type

Software revision

Description of Fault

Probable Cause (or causes) of Fault

S

Non

S

1.xx/

2.xx

4.xx 5.xx 6.xx

86

Unexpected SPI Interrupt.

• Interference (electrical noise)

87

Unexpected IRQ Interrupt

• Interference (electrical noise)

88

The buffer pointers and sample counter are

initialized incorrectly.

• This occurs if the boiler calibration

routine is executed when it was not

expected to, (caused by electrical noise

or ESD.)

89

The software state machine has detected

incorrect input parameters.

• Usually caused by noise and ESD.

90

Corrupted or not initialized chamber calibration

value

• This occurs when a new controller board

or microprocessor has been installed.

• This may also happen when the unit has

been subjected to a strong static

discharge corrupting the memory.

This occurs when a new controller board

or microprocessor has been installed.

This may also happen when the unit has

been subjected to a strong static

discharge corrupting the memory.

• Re-calibrate the chamber

thermocouple.

91

C

•

•

•

Re-calibrate the pressure sensor.

91

Corrupted or not initialized pressure calibration

•

•

•

95

•

CF_EEPROM_ERROR

• Failure to read EEPROM messages

from 4C512 EEPROM (EEPROM

not programmed)

94

•

CF_COMM_ERROR

• The LCD controller PCB failed to receive

messages from the Rev 7 PCB.

• • • No connection between Colour LCD

Controller and Rev 7PCB;

Check cable / connection.

• • • • Verify that MCU is properly inserted

into the socket on the Rev 7 PCB.

• Verify that 5V is available on the Rev 7

PCB (Green LED ON)

98

Microcontroller fails to communicate with ADC

(Analog to Digital Converter)

• Hardware failure.

• MCU not inserted properly in the socket

• Damaged ADC converter, replace PCB.

• If a PCB adapter is used, verify that

PCB adapter is properly secured in the

socket and that there are no bent pins

99

The microprocessor's internal watchdog

timer has tripped.

•

Incorrect operation of the software,

usually noise or ESD related.

Loading...

Loading...