Doc# E166703 4-17

4: Electrical Installation

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

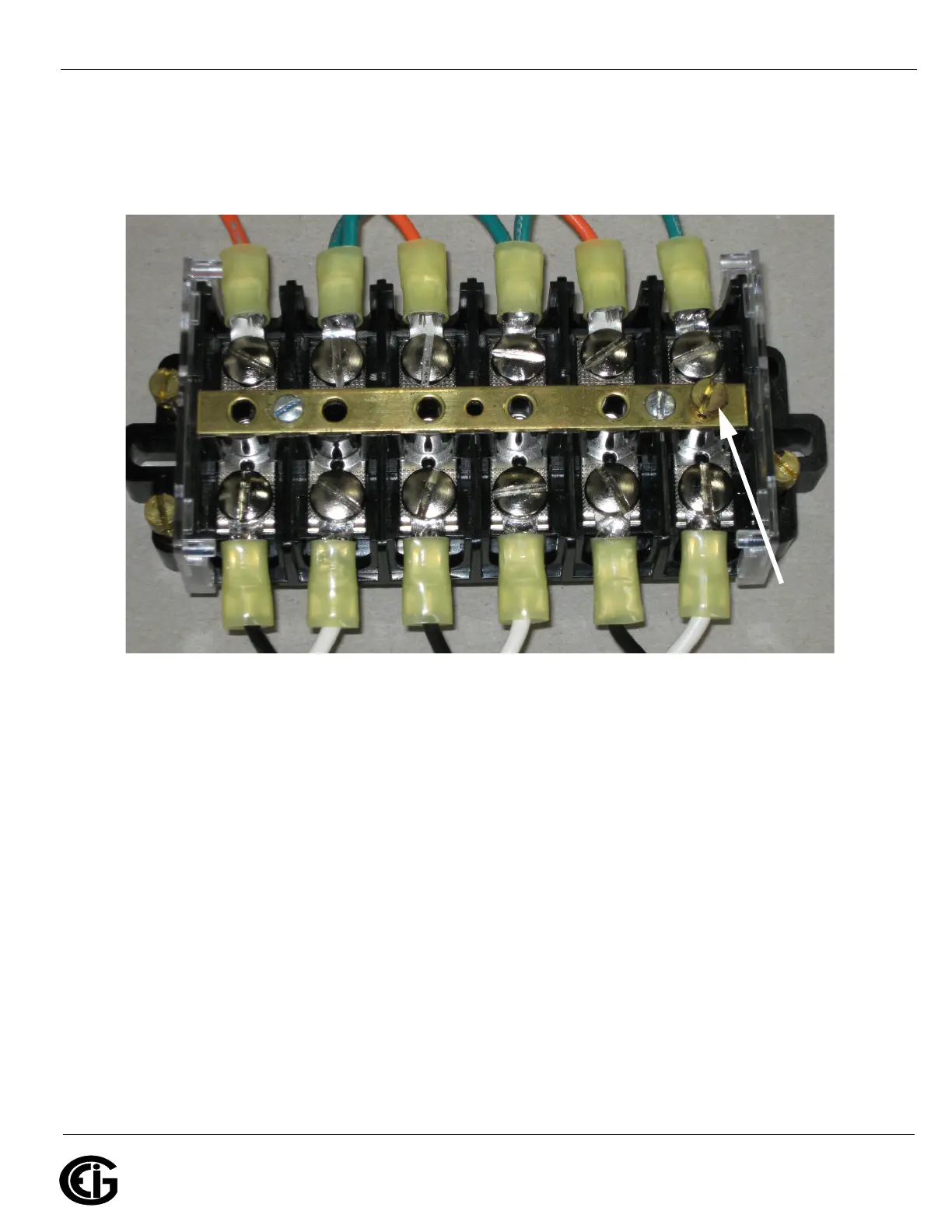

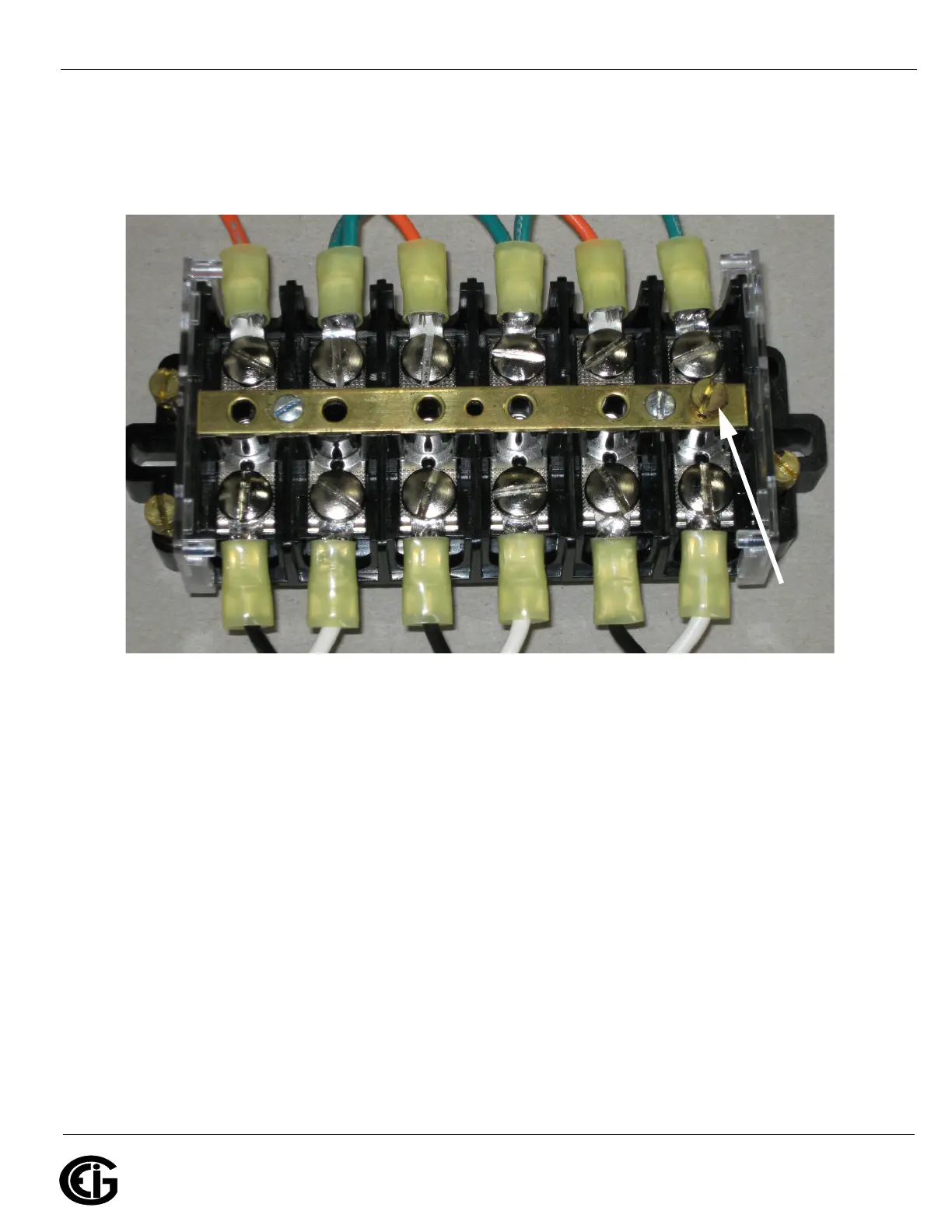

5. Remove one of the brass shorting screws from the plastic base and place it through

the brass shorting bar over one of the grounded terminals and tighten (max torque

of 16.2 in-lb, 1.8 N-m).

a. Verify that, when tightened, the screw head is in full contact with the brass bar.

Figure 4.6: EI SB-6TC with Shorting Screw Attached to Ground Terminal

6. Remove another brass shorting screw and place it through the brass bar over an

un-grounded lead of a CT and tighten (max torque of 16.2 in-lb, 1.8 N-m).

a. Verify that, when tightened, the screw head is in full contact with the brass bar.

7. If necessary, remove another brass shorting screw and place it through the brass

bar over an un-grounded lead of the second CT and tighten (max torque of 16.2 in-

lb, 1.8 N-m).

a. Verify that, when tightened, the screw head is in full contact with the brass bar.

8. If necessary, remove another brass shorting screw and place it through the brass

bar over an un-grounded lead of the third CT and tighten (max torque of 16.2 in-lb,

1.8 N-m).

a. Verify that, when tightened, the screw head is in full contact with the brass bar.

SHORTING

SCREW

ATTACHED TO

GROUND

Loading...

Loading...