Chapter 11 Operating Instructions

C4000 Select

56 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012247/RI61/2007-11-30

Technical specifications

Minimum Typical Maximum

Alignment laser Class 1 in accordance with IEC 60825@1:2007 and

2

1 CFR 1040.10 and 1040.11 except for

deviations pursuant to Laser Notice No. 50, June

24, 2007, optical output power 390 µW CW

typical

= 650 nm

Weight, type dependent

Depending on protective field height (see page 63)

Receiver unit

Switching outputs (OSSDs) Dual-channel, PNP semiconductor, short-circuit

protected

14)

, cross-circuit monitored

Response time See chapter 11.2 on page 58

Switch off time

15)

100 ms

Switching voltage

16)

17)

HIGH

(active, U

eff

)

U

V

– 2.25 V DC 24 V DC U

V

Switching voltage

16)

LOW

(inactive)

0 V 0 V 2.0 V DC

Switching current 0 mA 500 mA

Leakage current

18)

0.25 mA

Load capacity 2.2 µF

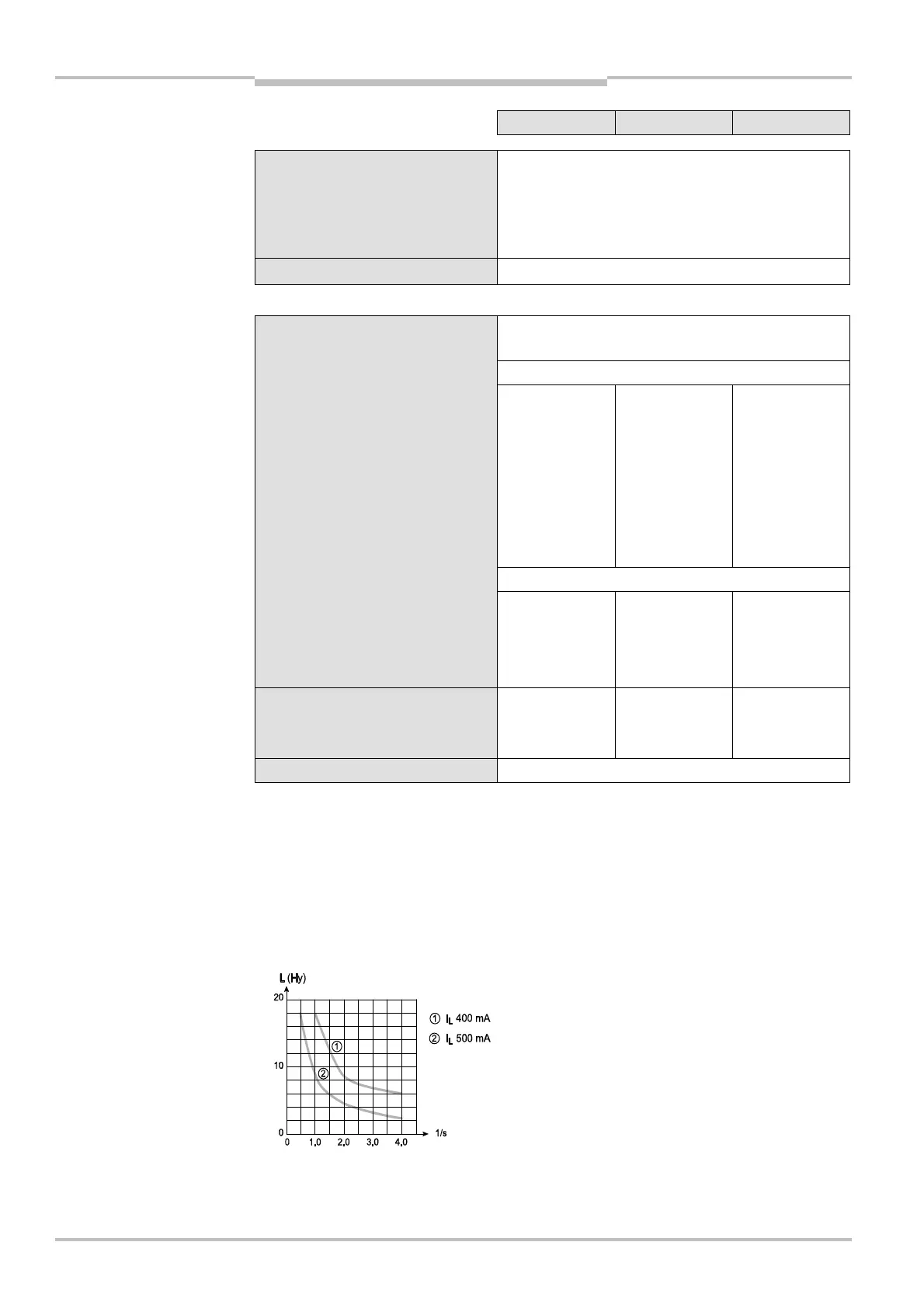

Switching sequence Depending on load inductance

Load inductance

19)

2.2 H

Test pulse data

20)

Test pulse width 120 µs 150 µs 300 µs

Test pulse rate 3

1

/s 5

1

/s 10

1

/s

Permissible line resistance

between device and load

21)

2.5

Supply lead 1

Power consumption See Tab. 30

14)

Applies to the voltage range between –30 V DC and +30 V DC.

15)

Switch off time represents the minimum amount of time that the OSSDs will be switched off when the C4000

Select transitions to an inactive (low) (i.e. red) state.

16)

As per IEC 61131@2.

17)

On the device plug.

18)

In the case of a fault (0 V cable open circuit) the max. leakage current flows in the OSSD cable. The down-

stream controller must detect this status as LOW. A FPLC (Fail-safe Programmable Logic Controller) must be

able to identify this status.

19)

The maximum rated load inductance is higher with lower switching sequence.

20)

When active, the outputs are tested cyclically (brief LOW). When selecting the downstream controllers, make

sure that the test pulses do not result in deactivation when using the above parameters.

21)

Make sure to limit the individual line core resistance to the downstream controller to this value to ensure that

a short-circuit between the outputs is safely detected. (Also note EN 60 204 Electrical Machine Equipment,

Part 1: General Requirements.)

Loading...

Loading...