17

8012704/YHS4/V2-0/2016-10 | SICK OPERATING INSTRUCTIONS | GM32

Subject to change without notice

PREPARING THE GAS DUCT SIDE 3

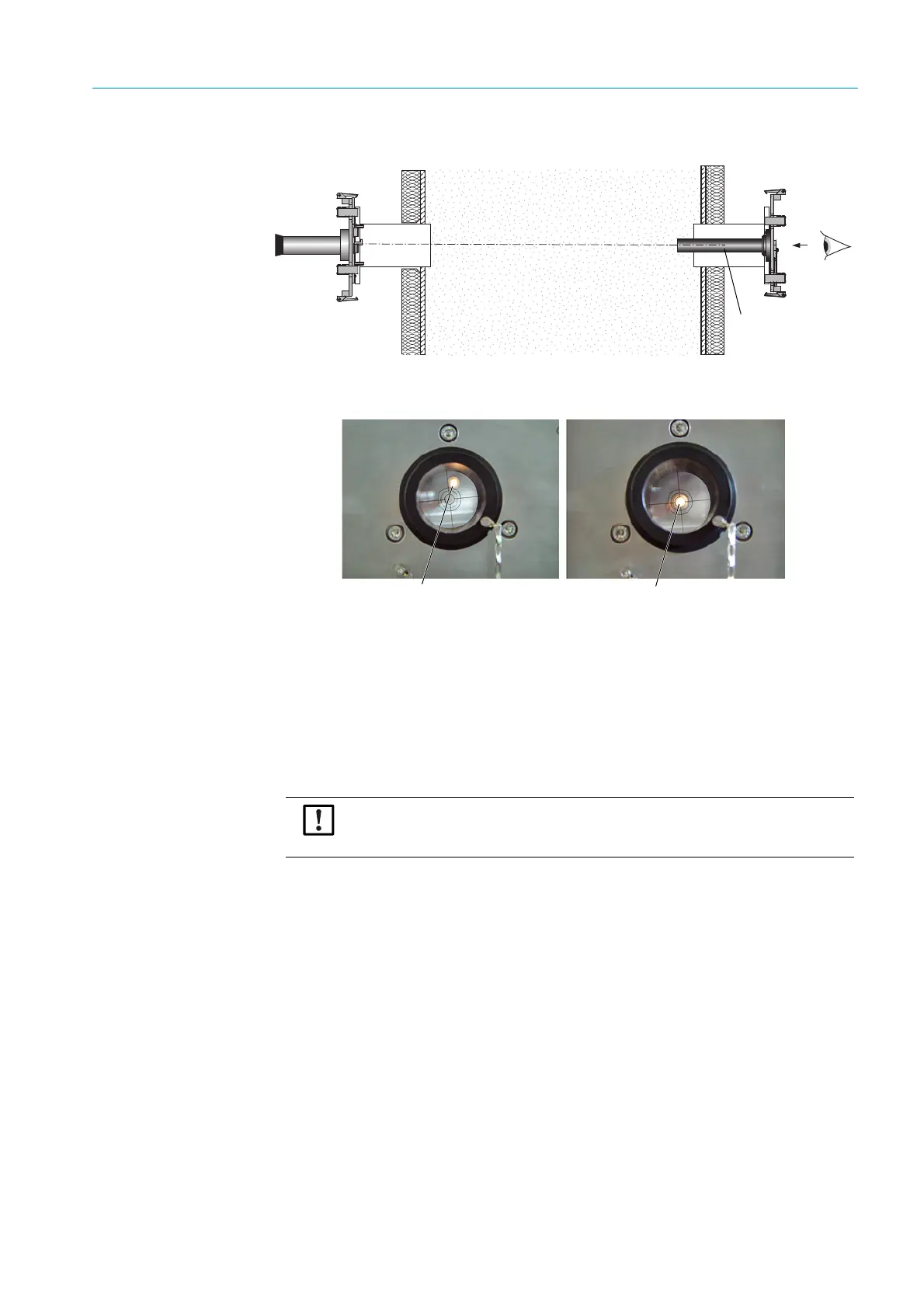

Fig. 6: Alignment of flanges by means of an adjustment device

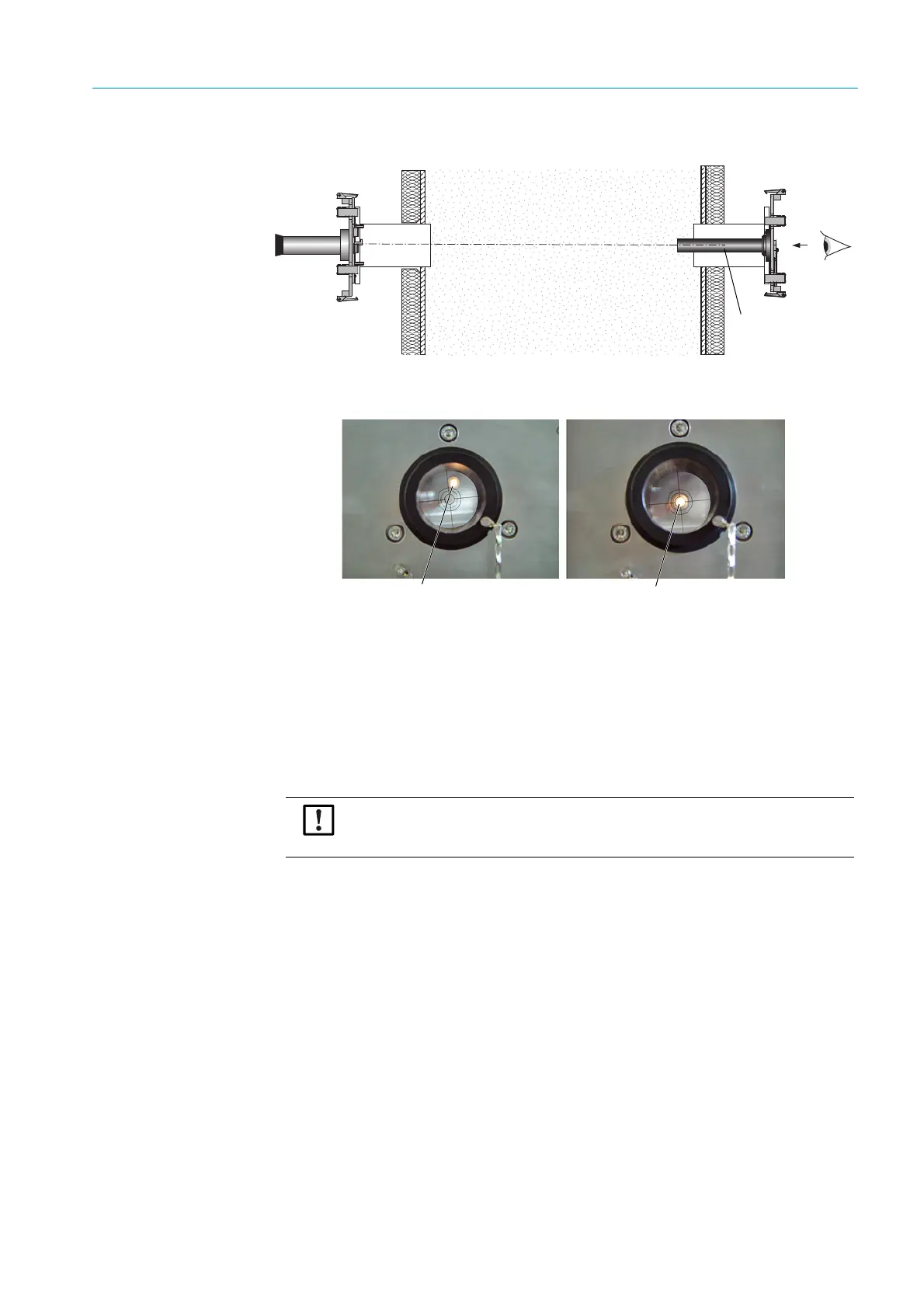

Fig. 7: Optical alignment display - on the adjustment tube window

– Interchange the adjustment device with light source and the adjustment tube. Align

the flange which contains the adjustment tube again: The light spot must be shown

centrally in the target of the adjustment tube, (see Fig. 7).

5 Perform the final attachment of the “flanges with tube” on the gas duct.

Make sure that the alignment of the flanges does not change.

6 Check the “active measuring path” dimension, the “flange - flange” dimension and the

alignment.

7 Remove the adjustment device again.

8 If necessary, attach duct insulation (protect GM32 from heat).

Light source

Adjustment tube

Align the flange with the

adjustment tube on the

side.

Not aligned correctly Aligned correctly

NOTE: Observe the ambient temperature of the GM32

▸ When the gas duct is hot, insulate the duct and flanges so that the GM32 is pro-

tected from high temperatures, see “System: GM32”, page 65.

Loading...

Loading...