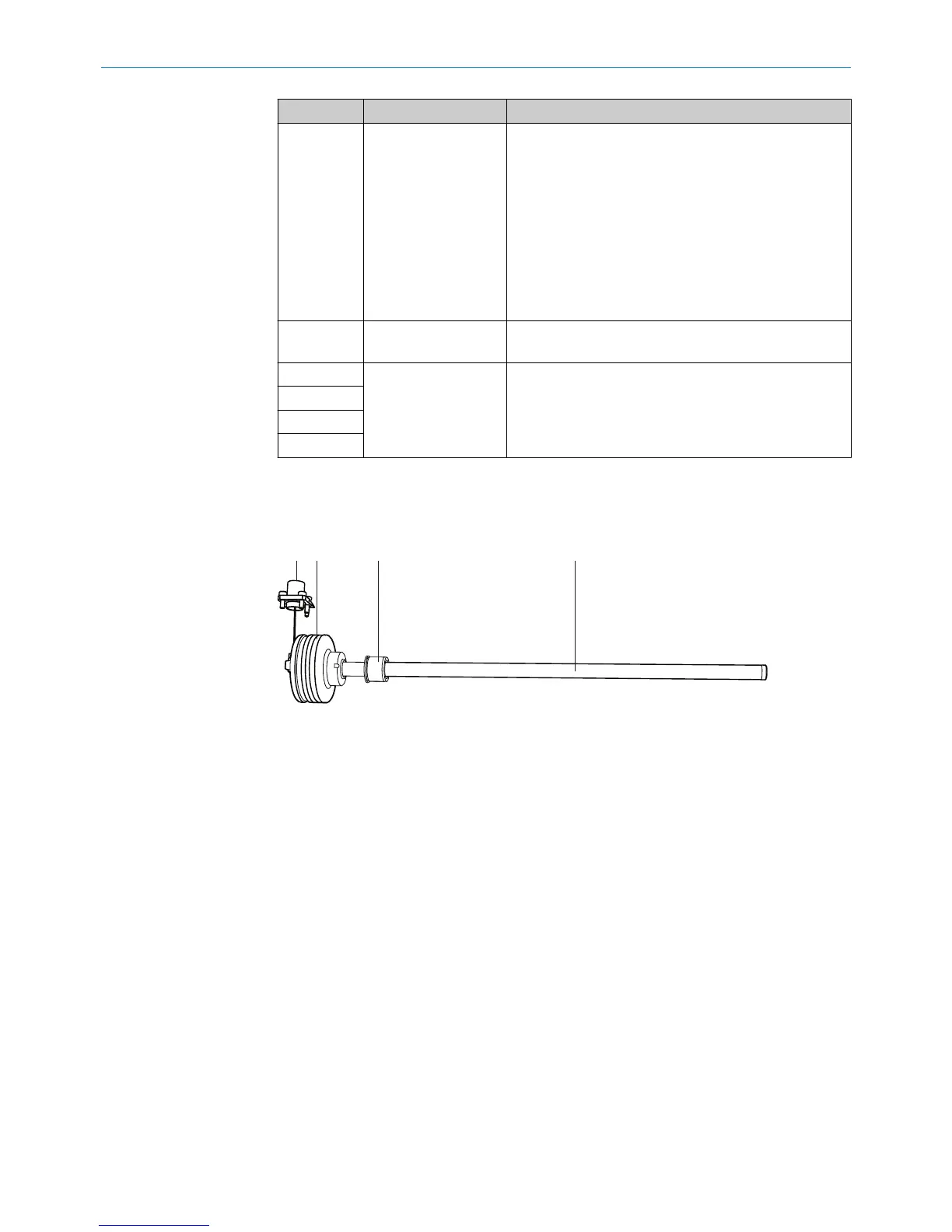

Position Meaning Description

13 Connection type A = M12 4-pin analog / PWM

(1 = VDC; 2 = n.c.; 3 = GND; 4 = SIG)

B = M12 4-pin analog / PWM

(1 = VDC; 2 = SIG; 3 = GND; 4 = n.c.)

M= M12 4-pin analog

(1 = n.c.; 2 = VDC; 3 = GND; 4 = SIG)

K = analog cable connection / PWM 3-wire cable

C = M12 5-pin digital

(1 = n.c.; 2 = VDC; 3 = GND; 4 = CAN_HI; 5 = CAN_LO)

D = M12 5-pin digital

(1 = VDC; 2 = n.c.; 3 = GND; 4 = CAN_HI; 5 = CAN_LO)

14 Connector length A = 60 mm M12

E = 100 mm M12

15 Measuring range

Position measurement

in 1 mm steps

e.g., 0300 = 50 ... 300 mm

16

17

18

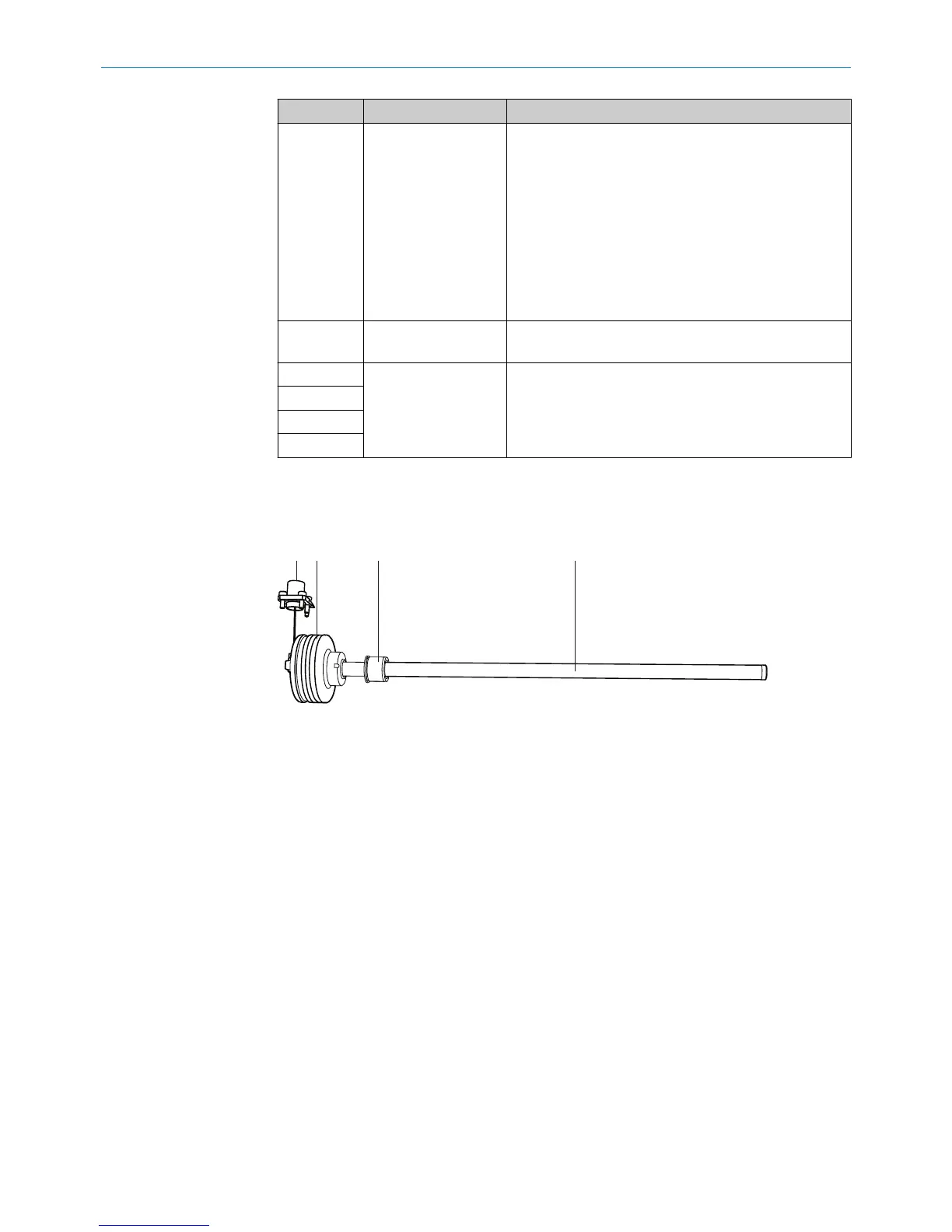

3.3 Construction and function

Construction of the device

Figure 1: MAX design

1

M12 connector system

2

Protective housing (electronics)

3

Position magnet

4

Pressure pipe

Connector system:

The M12 connector system requires very little time to attach. It is suitable for applica‐

tions in harsh environments up to IP69K (when using a suitable mating connector).

Protective housing (electronics):

The housing is designed to be installed in a hydraulic cylinder and protects the electron‐

ics against external influences.

Position magnet:

The position magnet is the only moving component in the measuring device when

installed in the piston. The position magnet is located inside the piston and moves over

the pressure pipe without contacting it. The magnet field that is produced during this

process defines the current position of the piston.

Pressure pipe:

The pressure pipe is a pressure-resistant structure that is immersed into the cylinder

piston rod. It contains the hermetically protected magnetostrictive sensing element.

3

PRODUCT DESCRIPTION

10

O P E R A T I N G I N S T R U C T I O N S | MAX 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Loading...

Loading...