Critical applications

If a safety function is not enabled in the inverter, then you can use the following critical

applications without any restrictions.

If a safety function is enabled in the inverter, then several applications can result in faults in

the safe actual value sensing. For active or enabled safety functions, faults and errors in the

safety-related actual value sensing initiate a stop response: Messages C01711, C30711 with

default values 1040 ff.

The stop response does not result in an unsafe drive state, but in a lower drive availability.

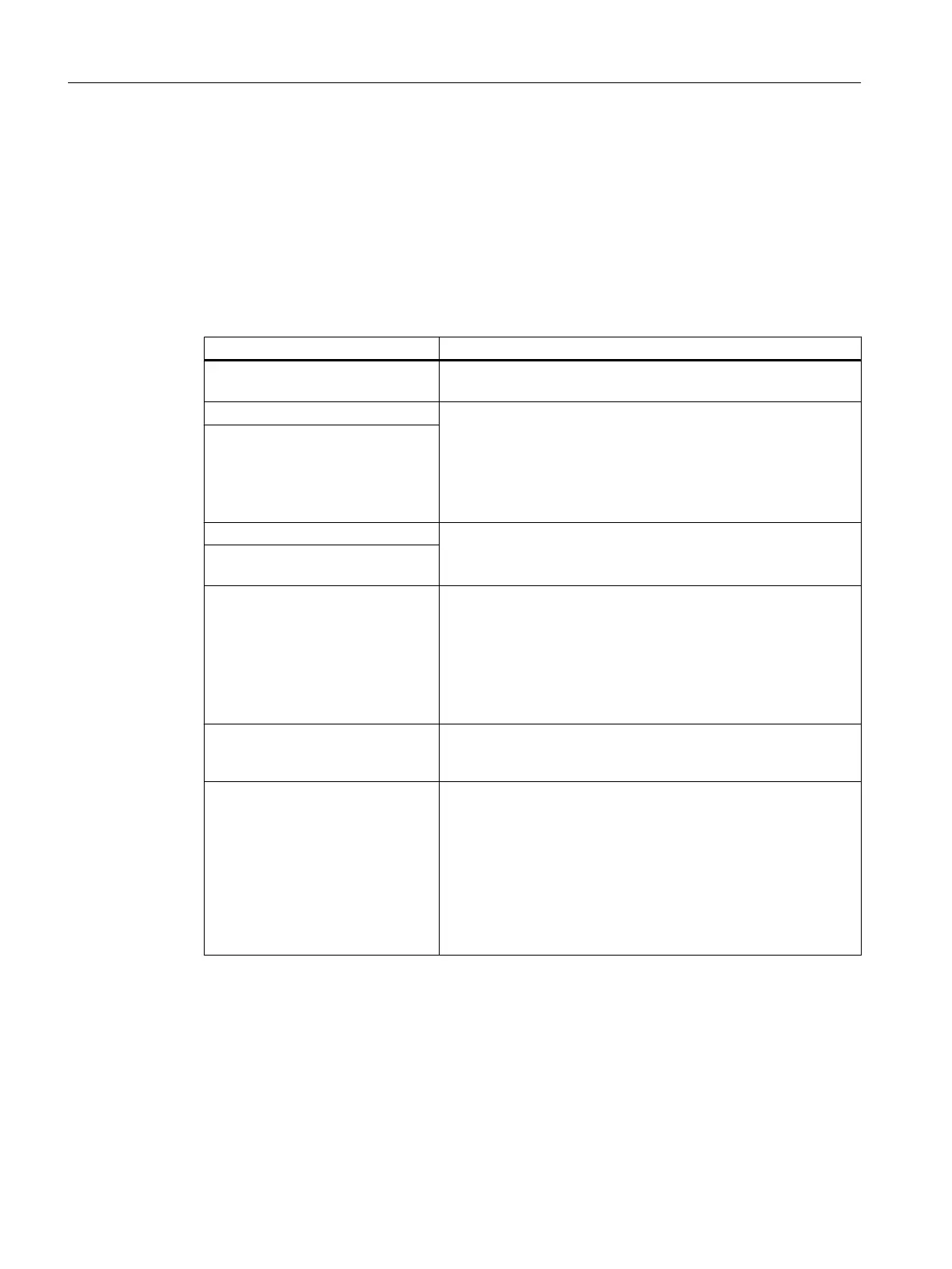

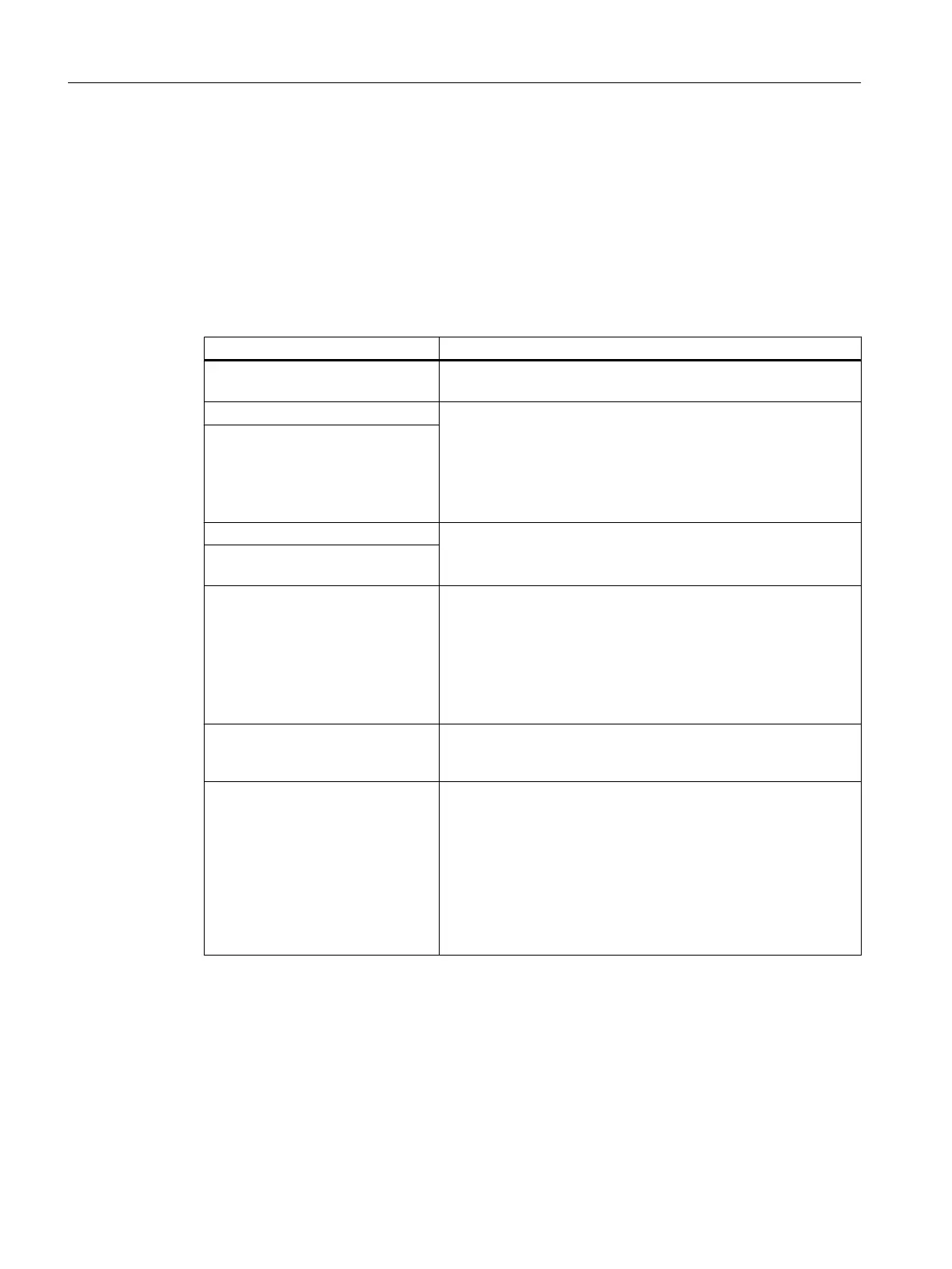

Critical application Remedy

Motor data identification during

commissioning

Only commission the safety functions after the motor data identi‐

fication has been completed.

Setpoint change as step function Set the ramp-function generator times to values > 0.5 s.

If you are using an inverter with position control, then you must

set the position controller and the travel profile so that there is

absolutely no overshoot in the speed/velocity characteristic.

Within 1 s, only one acceleration and one braking ramp are per‐

mitted. The cycle 0 → n

set

→ -n

set

→ 0 must be at least 2 s long.

Reversing the speed

Load change as step function Do not use the safety functions.

Continuous operation at speeds <

5 % of the rated speed

Switching-on the inverter with the

motor rotating ("flying restart" func‐

tion)

Avoid using the "flying restart" function when a safety function is

active.

Temporarily deactivate the safety function until the "flying restart"

function has been successfully completed.

It is not permissible that you use the "flying restart" function if you

are using the SSM function. It is not possible to deactivate SSM

using a control signal.

Operating an inverter at the current

limit

Select and dimension the drive so that the inverter current limit

does not respond. After commissioning, check that the inverter

does not reach its current or torque limits – even at full load.

Braking a motor using the "DC brak‐

ing" or "Compound braking" func‐

tions

Avoid using the "DC braking" or "Compound braking" functions

when a safety function is active.

If you require one of the two braking functions, in the risk assess‐

ment you must check where it is permissible that you deactivate

the safety function while braking. If yes, then deactivate the safety

function until braking has been completed.

If you use the SSM function, then it is not permissible to use the

two braking functions. It is not possible to deactivate SSM using

a control signal.

Description

3.5 Restrictions when using safety functions

Safety Integrated - SINAMICS G110M, G120, G120C, G120D and SIMATIC ET 200pro FC-2

28 Function Manual, 01/2017, FW V4.7 SP6, A5E34261271B AD

Loading...

Loading...