11.03 3 Safety-Related Functions

3.5 Safely-reduced speed (SG)

© Siemens AG 2003 All Rights Reserved

SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

3-103

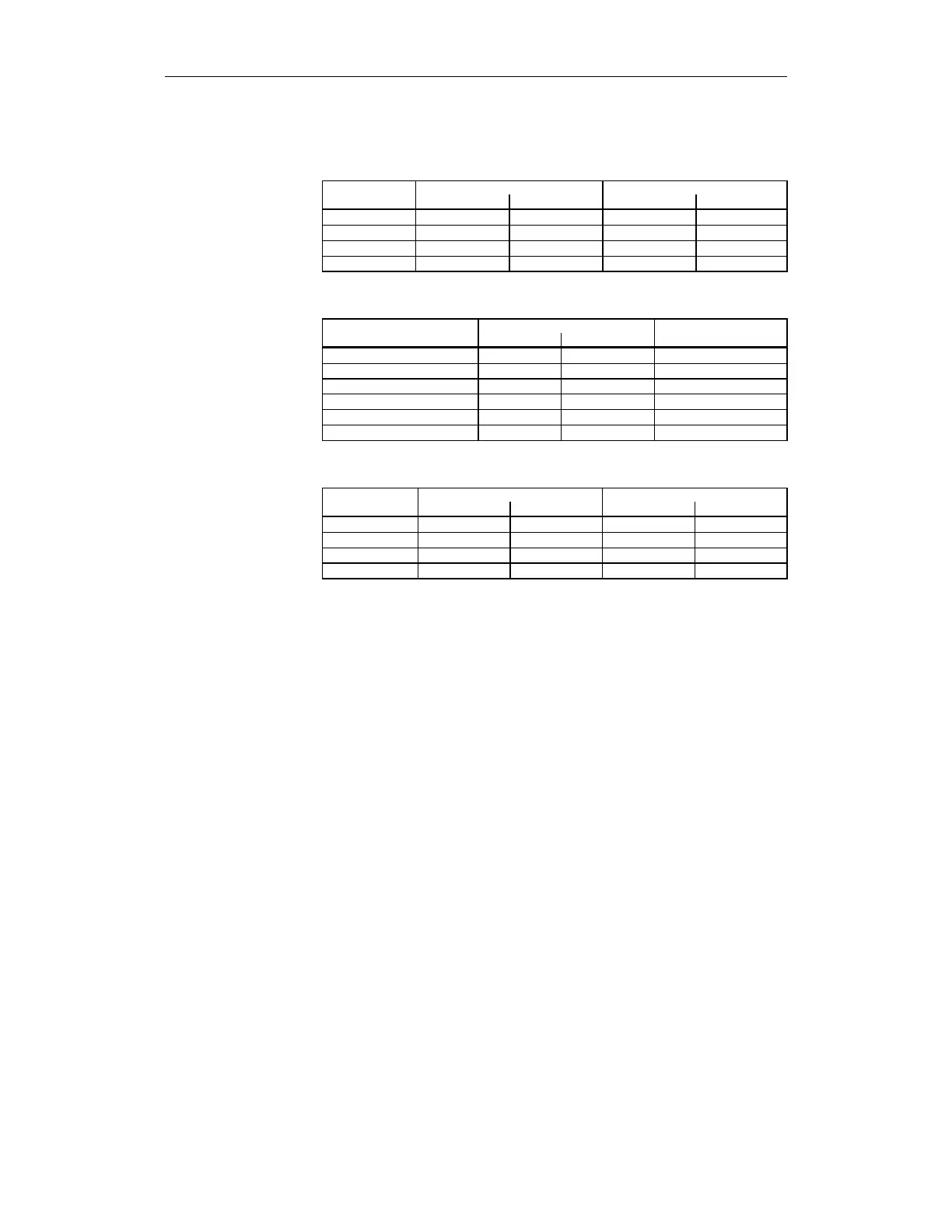

Table 3-28 Supplying MDs for SGEs

For 840D For 611 digital

Limit value MD number Value MD number Value

SG1

36931[0]

1000

1331[0]

1000

SG2

36931[1]

2000

1331[1]

2000

SG3

36931[2]

4000

1331[2]

4000

SG4

36931[3]

5000

1331[3]

5000

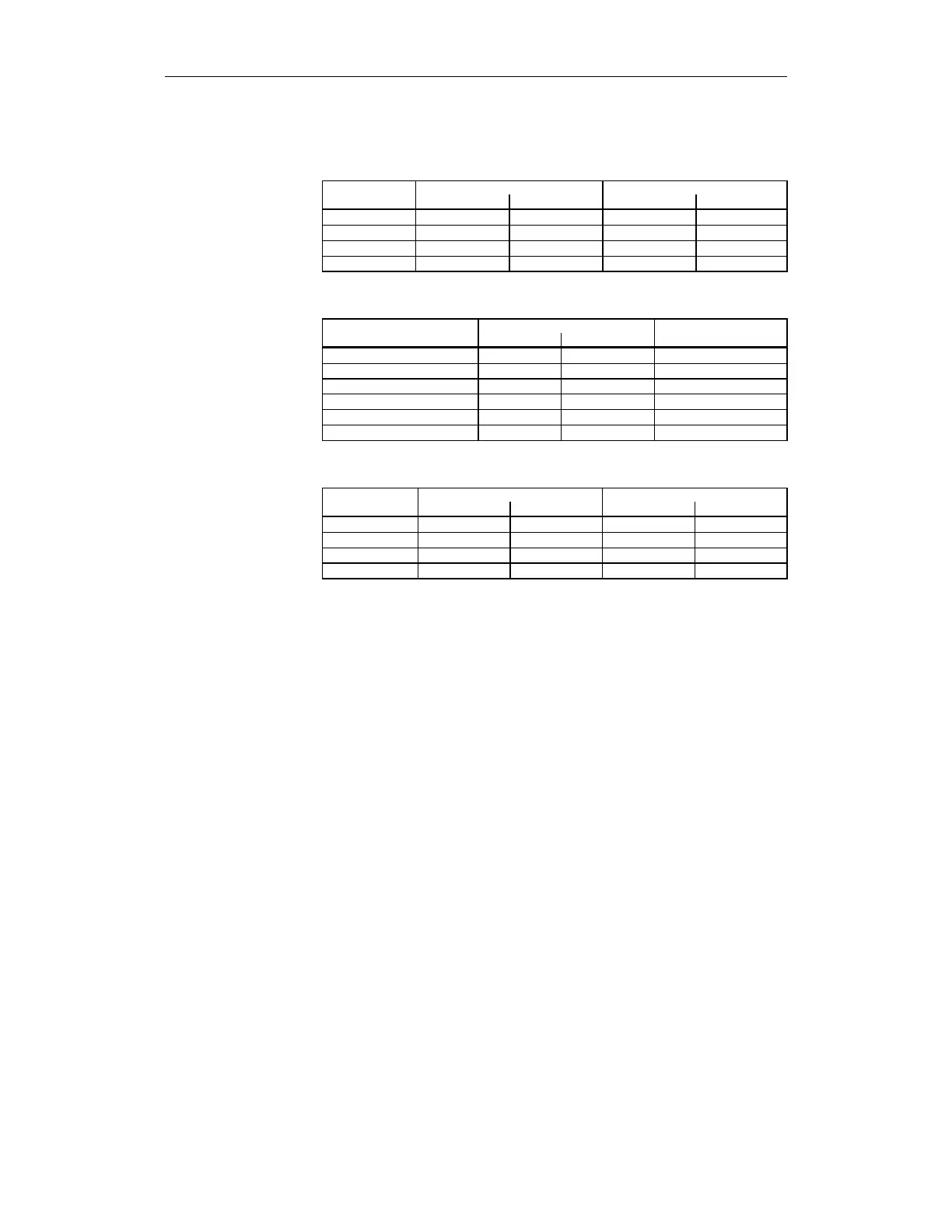

Table 3-29 Supplying MDs for SGEs

Signal Assignment

SGE MD number Value Remarks

SG select, bit 1

36972[1]

01 06 04 02

SG select, bit 0

36972[0]

01 06 04 01

SG override selection bit 3

36978

[

3

]

00 00 00 00 Not configured

SG override selection bit 2

36978[2]

00 00 00 00 Not configured

SG override selection bit 1

36978[1]

01 06 04 04

SG override selection bit 0

36978[0]

01 06 04 03

Table 3-30 Supplying MDs for override values

Override For 840D For 611 digital

MD number Value MD number Value

0

36932[0]

100

1332[0]

100

1

36932[1]

80

1332[1]

80

2

36932[2]

50

1332[2]

50

3

36932[3]

30

1332[3]

30

3.5.8 Application examples for SG

Please refer to Chapter 7, "Configuring example" for an example of safely-

reduced speed.

3.5.9 Examples for safe input of ratios

The gear ratio (encoder/load) must be safely sensed on a spindle with a four-

stage gearbox.

Two examples are given, one with a

2-encoder system (ex. 1, refer to Fig. 3-13 Spindle with a 2-encoder system)

and one with a

1-encoder system (ex. 2, refer to Fig 3-14 Spindle with a 1-encoder system).

Example 1: Spindle with a 2-encoder system

The two channels are monitored by comparing the speed sensed by the second

encoder with the speed of the motor encoder, taking the gear ratio into account.

The ratio selection does not have to be safely monitored and only has to

involve one channel.

• The gear stage is selected from an NC program with an H function via the

PLC user program.

Defining machine data

Task assignment

Assumptions for

example 1

Loading...

Loading...