2 General Information about Integrated Safety Systems 11.03

2.6 Basics of SINUMERIK Safety Integrated

© Siemens AG 2003 All Rights Reserved

2-32 SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

2.6 Basics of SINUMERIK Safety Integrated

2.6.1 Control category 3

The safety-relevant components of the SINUMERIK 840D control with

SIMODRIVE 611 digital correspond to Category 3 according to EN 954-1.

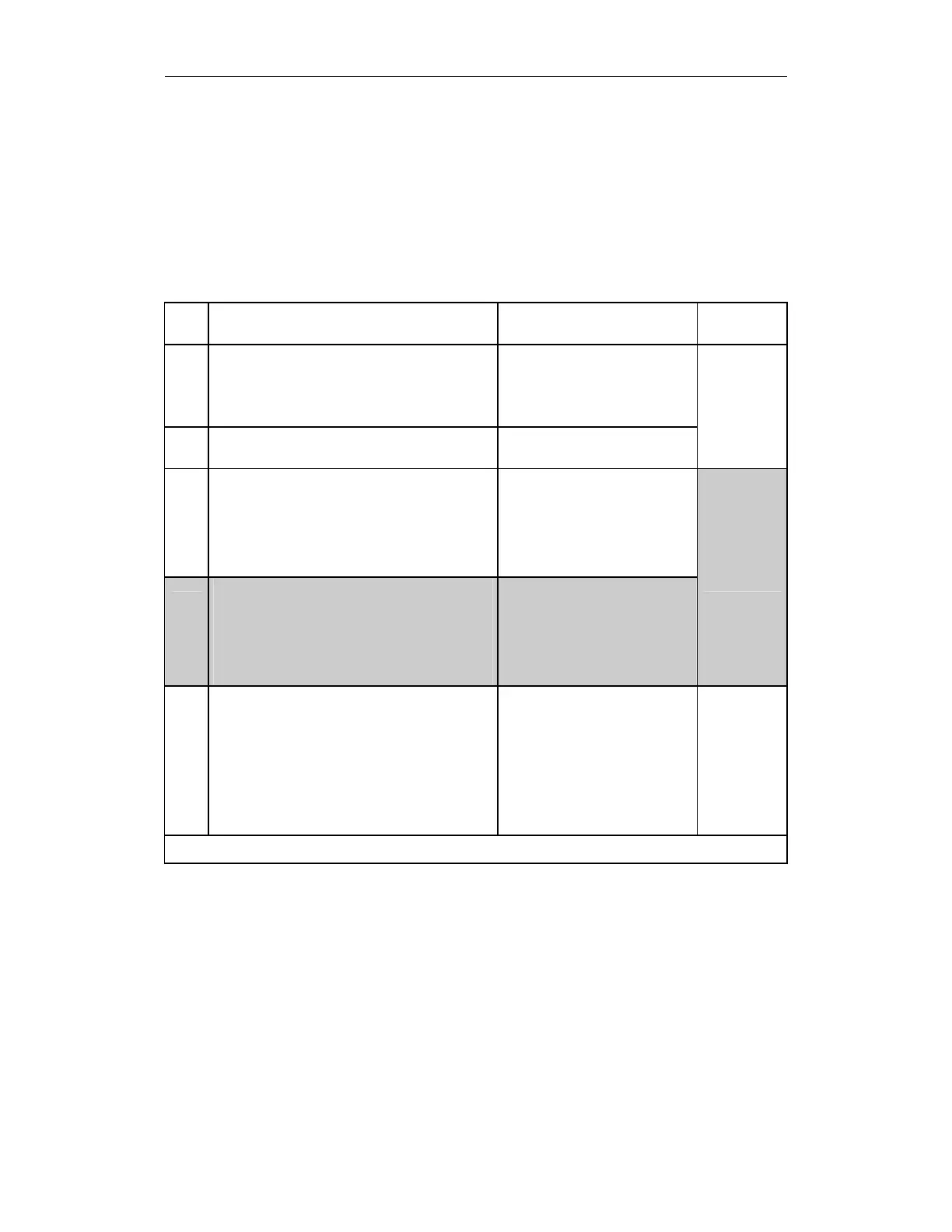

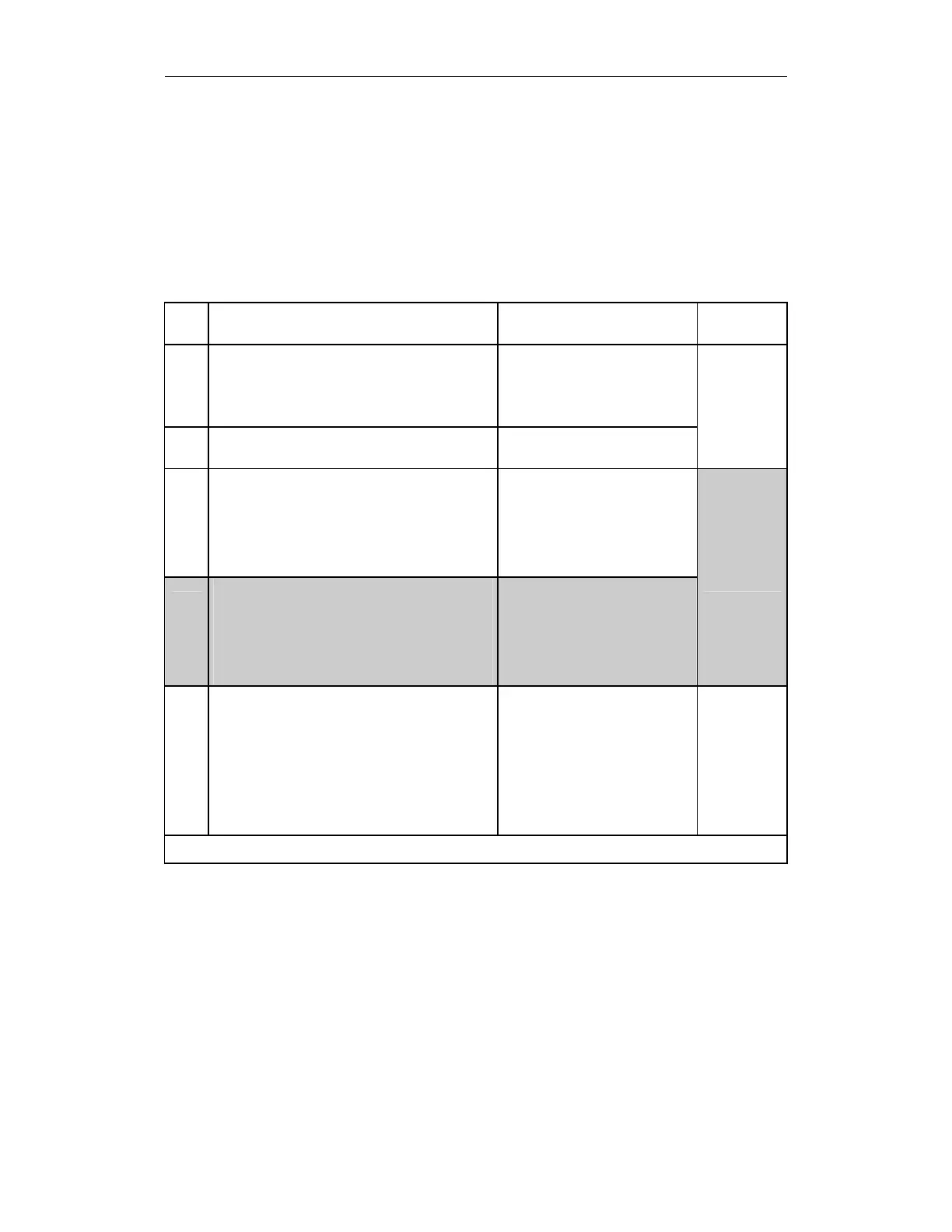

Table 2-5 Categories of safety-relevant parts of control systems

Cate-

gory

Summary of requirements System response

1)

Main principle

for provision

of safety

B The safety-relevant components of machine controls

and/or their protective equipment and components

must be designed, constructed, selected, assembled

and combined in compliance with all applicable

standards such as to be capable of withstanding all

potentially hazardous influences.

If a fault/error occurs, it can lead to

loss of the safety functions.

Selection of

components

1 The requirements of B must be fulfilled. Use of

components and principles that have proven to be

effective in terms of safety.

As described for category B, but

with a greater safety-relevant

reliability of safety functions.

2 The requirements of B must be fulfilled. Use of

principles that have proven to be effective in terms of

safety.

The safety function(s) must be tested at appropriate

intervals by the machine control.

Note:

The suitability of the measure depends on the

application and type of the machine.

The occurrence of a fault/error can

lead to a loss in safety functions

in-between tests.

The loss of safety function(s) is

detected in the course of testing.

Structure-

based

3 The requirements of B must be fulfilled. Use of

principles that have proven to be effective in terms of

safety.

The controls must be designed such that:

a single fault/error in the control system does not

cause a loss of the safety function, and

if it can be implemented in an appropriate way,

individual faults/errors can be detected.

If the single fault/error occurs, the

safety function always remains

operational.

Some, but not all, faults/errors are

detected.

An accumulation of undetected

faults/errors can lead to a loss of the

safety function(s).

4 The requirements of B must be fulfilled. Use of

principles that have proven to be effective in terms of

safety.

A control system must be designed such that:

a single fault/error in the control system does not

cause a loss of the safety function(s), and

the single fault/error is detected before or as the

safety function is required to take effect. If such a

response cannot be implemented, then the

accumulation of faults/errors must not result in a loss

of the safety function(s).

If faults/errors occur, the safety

function always remains

operational.

Faults/errors are detected promptly

enough to prevent any loss of safety

functions.

Structure-

based

1): The risk assessment states whether the total or partial loss of the safety function(s) as a result of faults/errors

is acceptable.

General

Loading...

Loading...