3 Safety-Related Functions 11.03

3.11 Encoder mounting arrangements

© Siemens AG 2003 All Rights Reserved

3-168 SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

3.11 Encoder mounting arrangements

3.11.1 Encoder types

The following basic types of encoder can be used on a drive module for the

purpose of safe operation:

• Incremental encoder

with sinusoidal voltage signals A and B (signal A is in quadrature with

signal B) and a reference signal R

e.g.: ERN 1387, LS 186, SIZAG2

• Absolute encoder

with EnDat interface and incremental, sinusoidal voltage signals A and B

(signal A is in quadrature with signal B)

e.g.: EQN 1325, LC 181

Various combinations can be derived from the basic types.

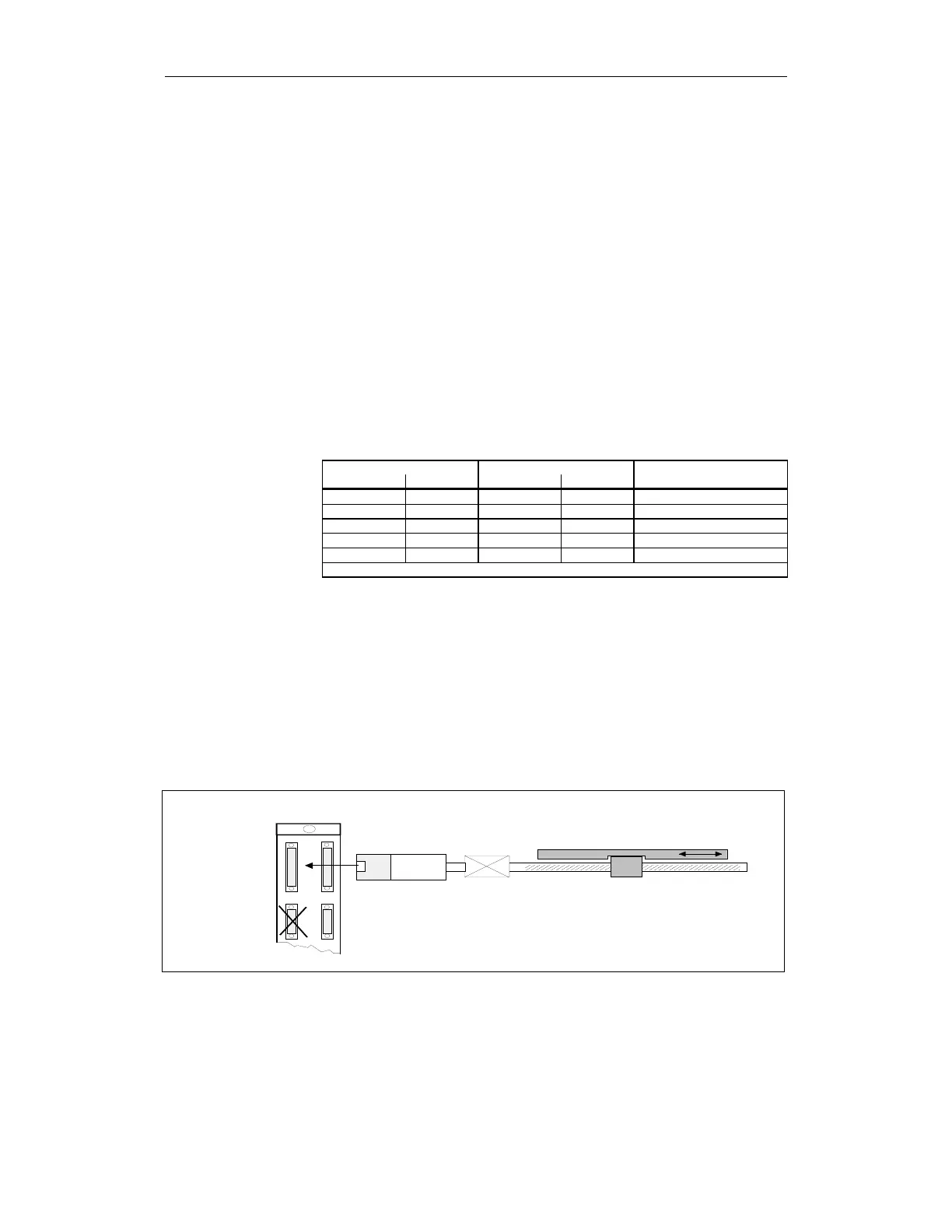

Table 3-64 Combinations of encoder types

Incremental encoder Absolute encoder

at the motor at the load at the motor at the load Comments

x 1-encoder system

x 1-encoder system

x x 2-encoder system

x x 2-encoder system

x x 2-encoder system

Note: x Encoder connection

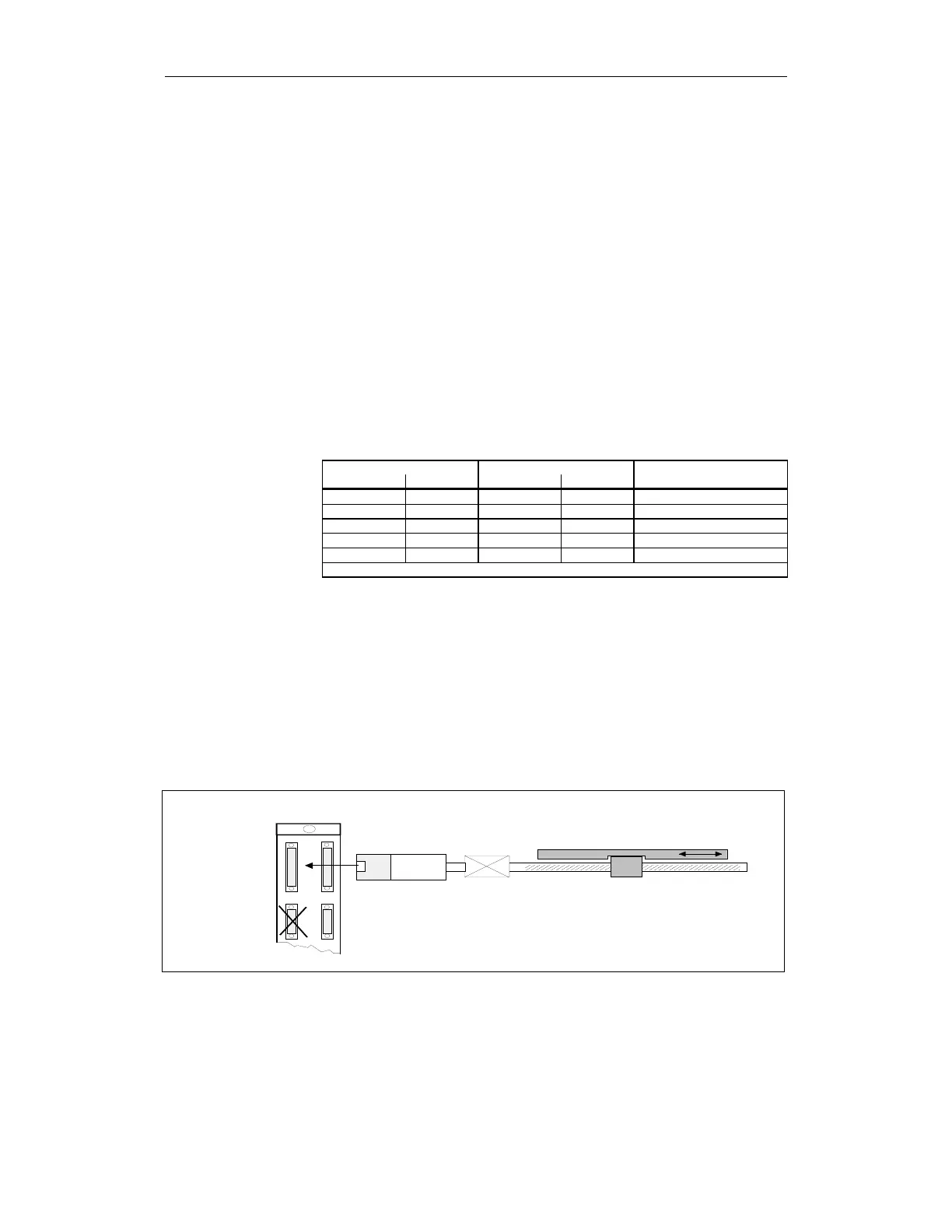

For a 1-encoder system, the incremental or absolute encoder at the motor is

used for the actual values of the NC and drive.

The 611 digital control module supplies one actual value to the NCK and drive

via 2 separate actual value channels..

Special feature for linear motors:

For linear motors, the motor encoder (linear scale) is also the measuring

system at the load. IMS and DMS are one measuring system. The connection

is made at the IMS input of the 611 digital control module.

Geber

Getriebe

Lose

GEBER_02.DSF

Anschluß

des

Motorgebers

(IMS)

Motor

(VSA)

Maschinentisch

VSA

Anschluß

des direkten

Lagegebers

(DM S)

Fig. 3-39 1-encoder system for a feed drive

Basic types

Combinations of

encoder types

1-encoder system

Loading...

Loading...