11.03 3 Safety-Related Functions

3.9 Safety-related input/output signals (SGE/SGA)

© Siemens AG 2003 All Rights Reserved

SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

3-129

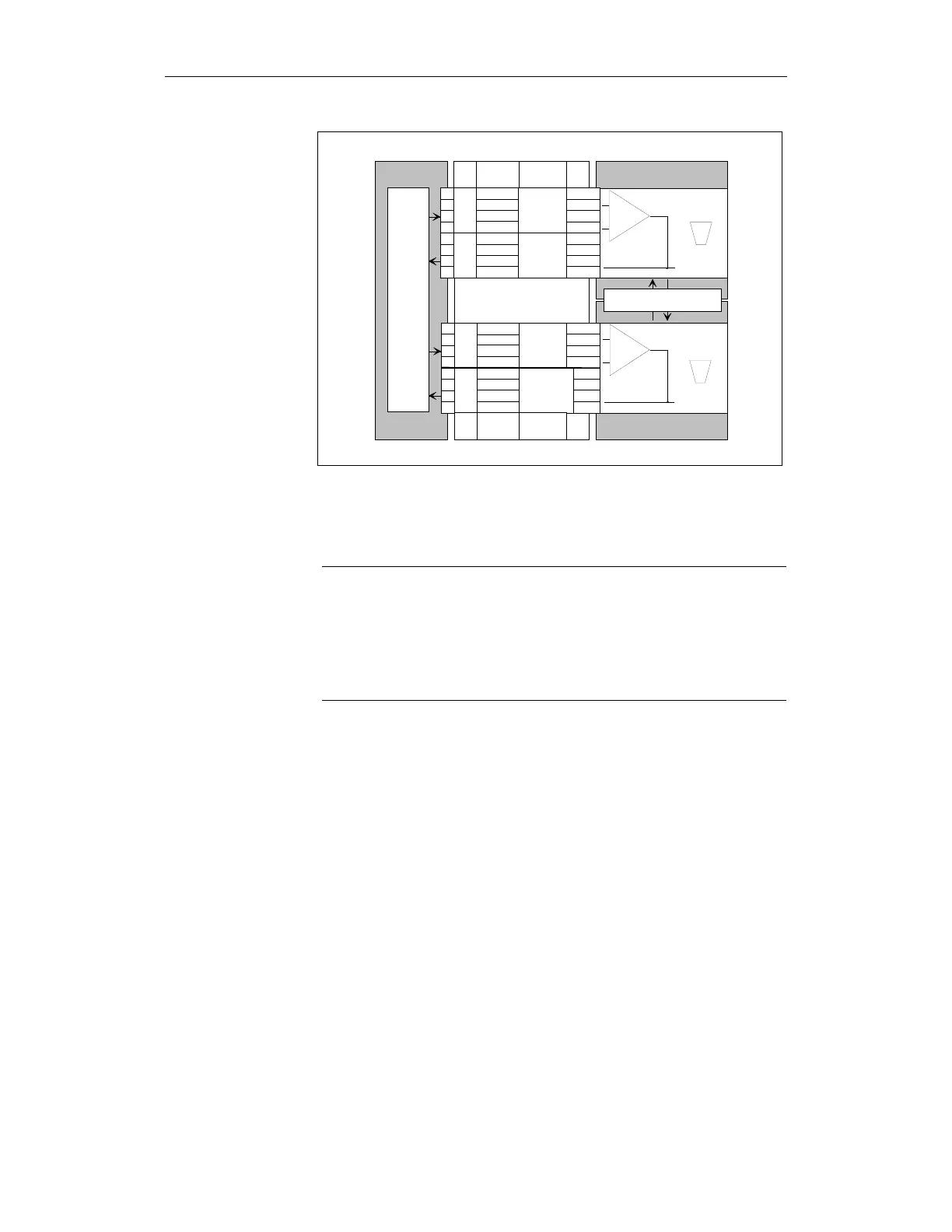

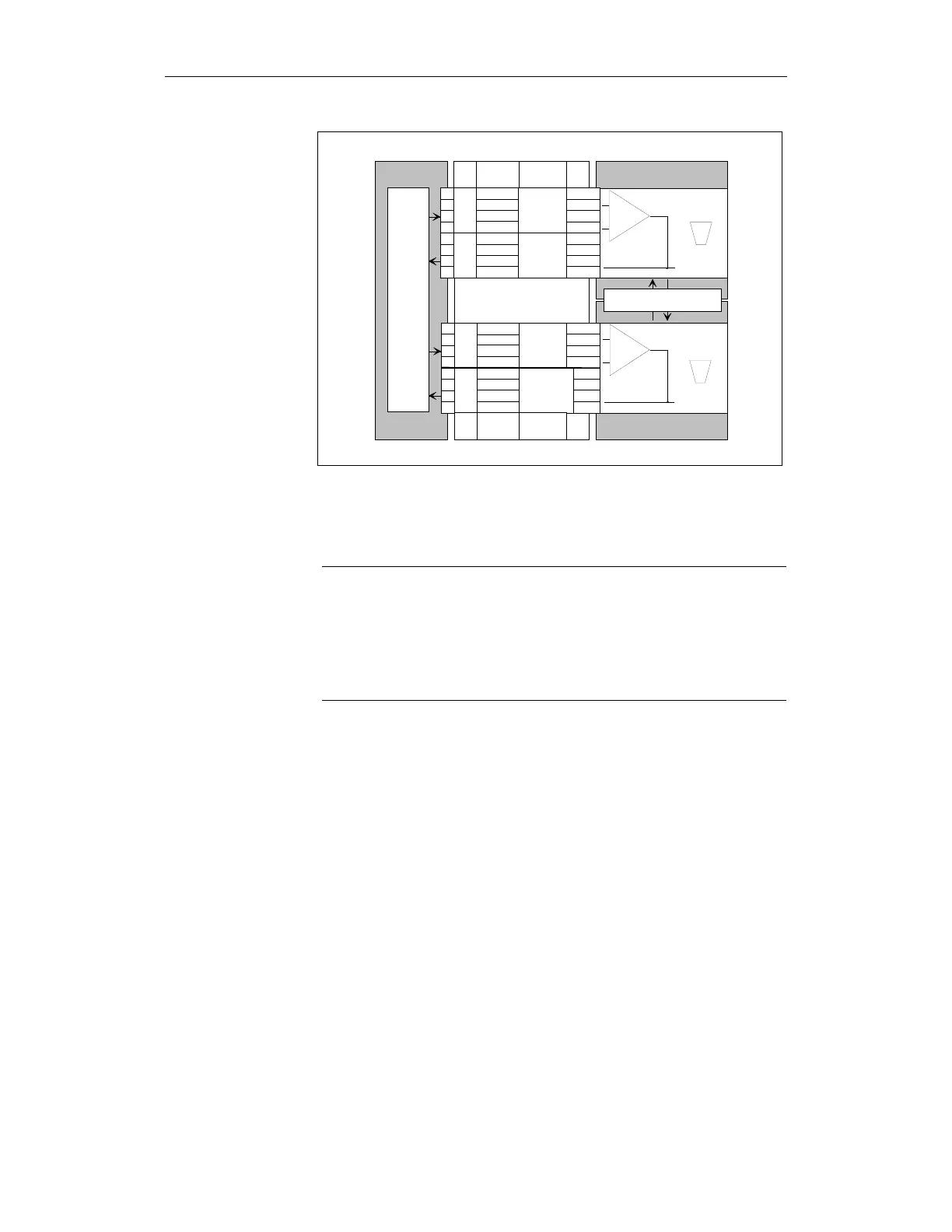

Process User

System

Machine

NCK

HW

I/O

I/O images

Processing

SGE

SGA

NCK

monitoring channel

SBH/SG

SE

SN

per axis/spindle

I1

I_Fig1

SGE ...

Multiple

distribution

...

I2

I_Fig2

SGE ...

In

...

I_Fign

...

SGE ...

O1

O_Fig1

SGA ...

Multiple

assignment

...

O2

O_Fig2

SGA ...

On

...

O_Fign

...

SGA...

I1

I_Fig1

SGE ...

PLC

user

program

...

I2

I_Fig2

SGE ...

In

...

I_Fign

...

SGE ...

O1

O_Fig1

SGA ...

...

O2

O_Fig2

SGA ...

On

...

O_Fign

SGA...

SBH/SG

SE

SN

per axis/spindle

PLC

HW

I/O

I/O images

Processing

SGE

SGA

Drive monitoring channel

PLC

user

program

Monitoring

comparators

Result and data

cross-check

SGESGA01.DS4

Monitoring

comparators

Fig. 3-28 Two-channel processing of I/O signals

The data and results in the two mutually independent monitoring channels are

subject to a crosswise data comparison. If any discrepancy is found, STOP F is

activated.

Note

Owing to the two-channel structure of Safety Integrated, the machine

manufacturer must supply the SGEs and SGAs in both the NCK monitoring

channel and the drive monitoring channel.

The actual signal status of the SGEs/SGAs is selected via the menu "Service

display". The "Service SI" window displays information about Safety

Integrated data together with the associated axis name and axis number.

For a two-channel control structure, only a single-channel signal feedback via

the PLC is needed.

In contrast, when a single-channel control structure is used, a redundant, i.e. a

two-channel feedback structure is required.

The following SGEs and SGAs are provided for each axis/spindle in each of the

two monitoring channels:

Basic principle of safe

signal processing

What SGEs/SGAs are

there?

Loading...

Loading...