4 Data Descriptions 11.03

4.1 Machine data

© Siemens AG 2003 All Rights Reserved

4-228 SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

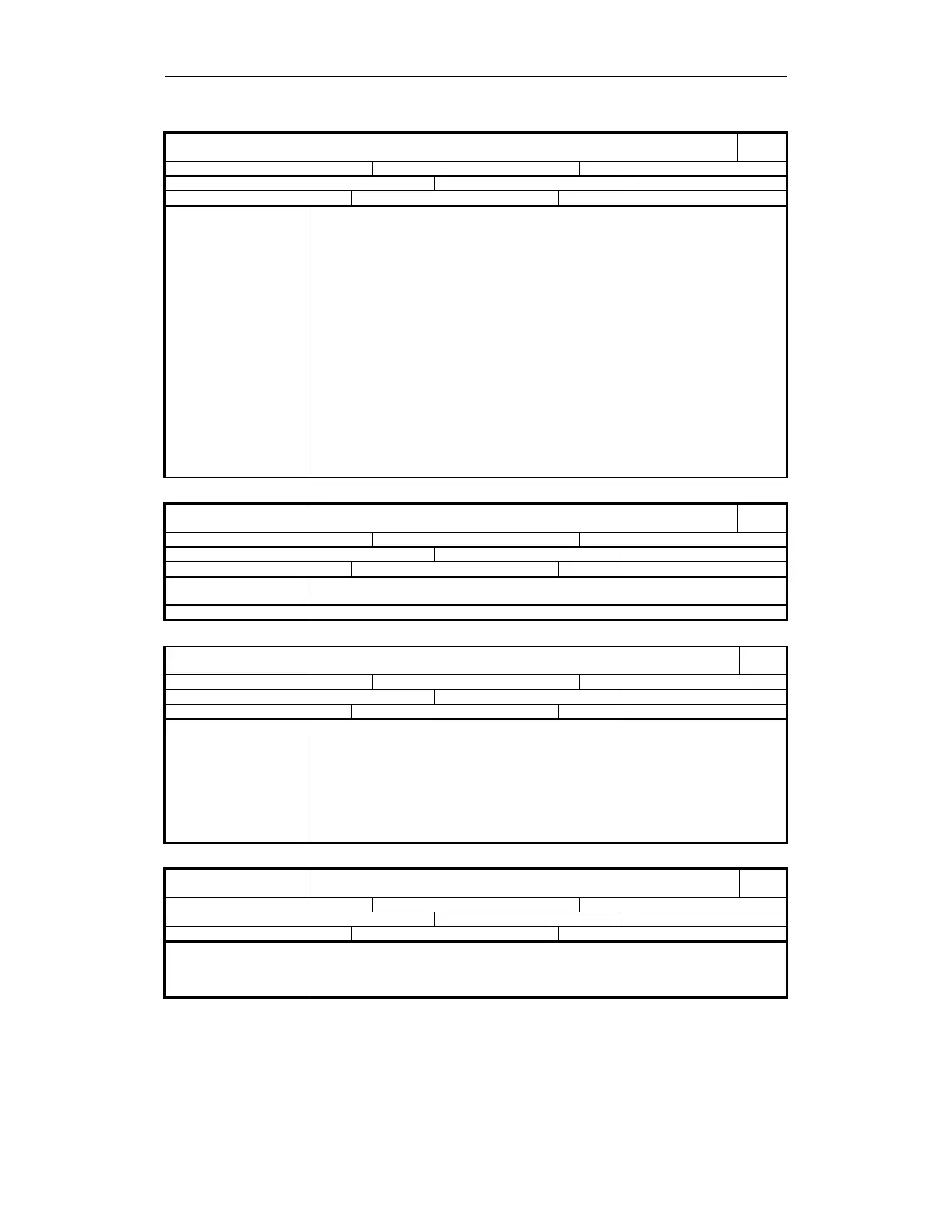

36964

MD number

$MA_SAFE_IPO_STOP_GROUP

Grouping safety IPO response

840D

Default: 0 Min. input value: 0 Max. input value: 1

Change effective after RESET Protection level (R/W) 7/2 Unit: -

Data type: BYTE Applies from SW 4.4.18

Meaning This MD influences the channel-wide IPO stop response distribution of Safety Integrated.

It is only effective for Safety Integrated axes/spindles.

0 = All other axes-spindles in the channel are notified of the

IPO stop response of this axis (default)

• 1 = For internal STOPs, the axes and machining spindles, interpolating with the

axis involved, are also additionally influenced via the initiated safety alarms. On

the other hand, other axes/spindles in the channel continue to run without

any disturbance.

For external STOPs (without alarm) all of the other axes/spindles remain

unaffected by the safety axis/spindle stop. This allows, for example, the

pulses of the spindle to be safely cancelled (using an external STOP A) so that

this spindle can be manually rotated and the axis can still be safely monitored

when moving.

If, in some machining situations, the other axes/spindles should stop together

with the safety/axis/spindle, then the user is responsible in implementing this using PLC or

synchronous action logic combinations.

36965

MD number

$MA_SAFE_PARK_ALARM_SUPPRESS

Suppression of Alarm "Axis not safely referenced" during parking

840D

Default: FALSE Min. input value: - Max. input value: -

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: -

Data type: BOOLEAN Applies from SW 5.2

Meaning Enable the suppression of Alarms 27000/300950 "Axis not safely referenced" when the

"Parking" function is selected.

Corresponds with …

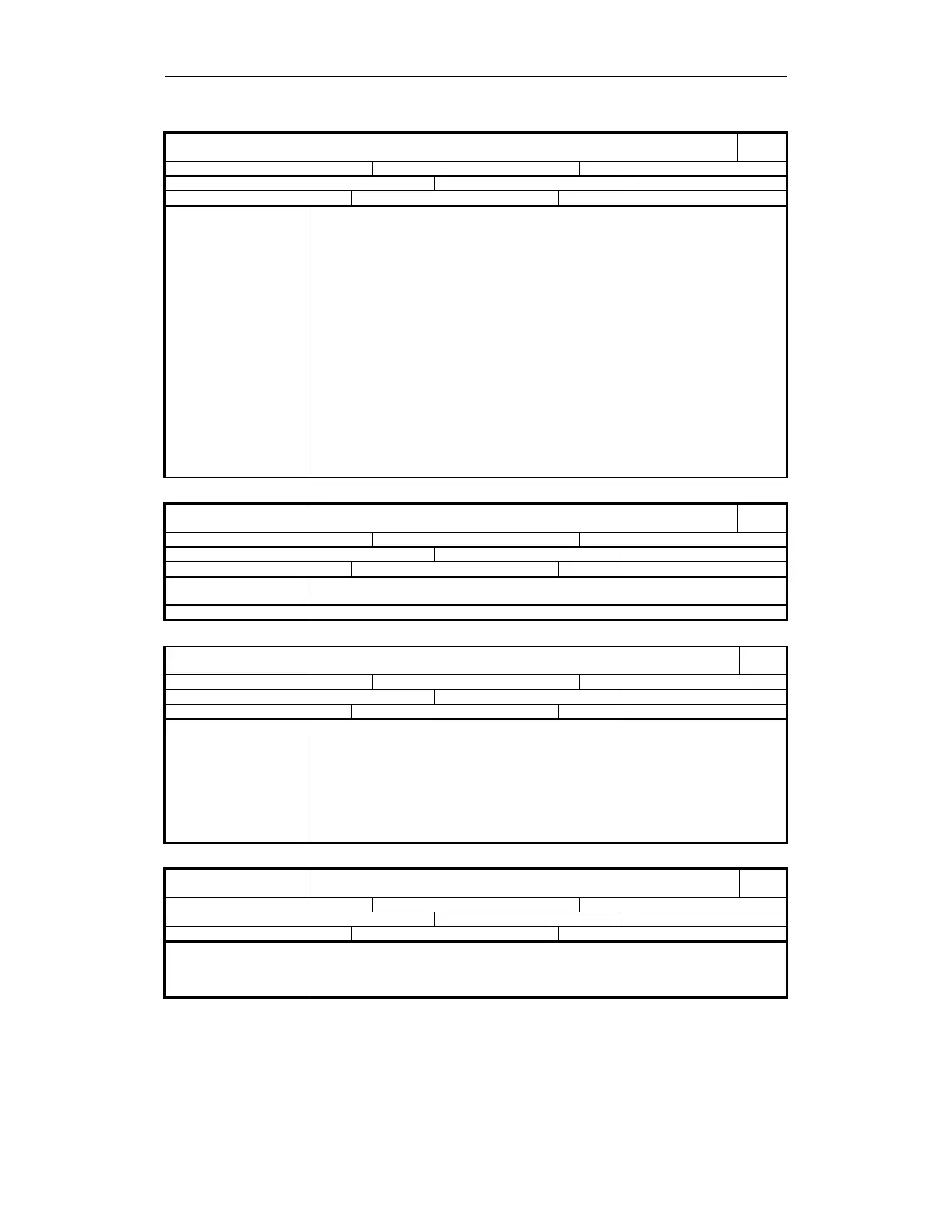

36966

MD number

$MA_SAFE_BRAKETEST_TORQUE

Brake test, holding torque

840D

Default: 5% Min. input value: 0 Max. input value: 800

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: %

Data type: DOUBLE Applies from SW 6.3.21

Meaning Specifies the torque or force for the function test of the brake mechanical system. The

holding brake must be capable of applying this torque without any axis slippage.

Activating the appropriate test function via MD $MA_FIXED_STOP_MODE, bit 1. This MD

must be a minimum of 10 % above the actual torque when selecting the brake test (i.e.

with the brake open). This guarantees that if the brake is defective, the motor can again

brake the axis. If this is not the case, the brake test is aborted with Alarm 20095.

If the drive MD 1192 is not correctly parameterized, then the required safety margin is

increased by twice the margin between the real torque and that parameterized in MD

1192.

36967

MD number

$MA_SAFE_BRAKETEST_POS_TOL

Position tolerance, brake test

840D

Default: 1 Min. input value: 0 Max. input value: -

Change becomes effective after POWER ON: Protection level (R/W) 7/2 Unit: mm/degrees

Data type: REAL Applies from SW 6.3.21

Meaning Maximum position tolerance for the function test of the brake mechanical system. If the

axis position deviates from the position by more than this tolerance, when the brake test is

selected, then the function test for the brake mechanical system is aborted.

The corresponding test function is activated via MD $MA_FIXED_STOP_MODE, bit 1.

Loading...

Loading...