11.03 2 General Information about Integrated Safety Systems

2.12 Error analysis

© Siemens AG 2003 All Rights Reserved

SINUMERIK 840D/SIMODRIVE 611 digital SINUMERIK Safety Integrated (FBSI) - Edition 11.03

2-47

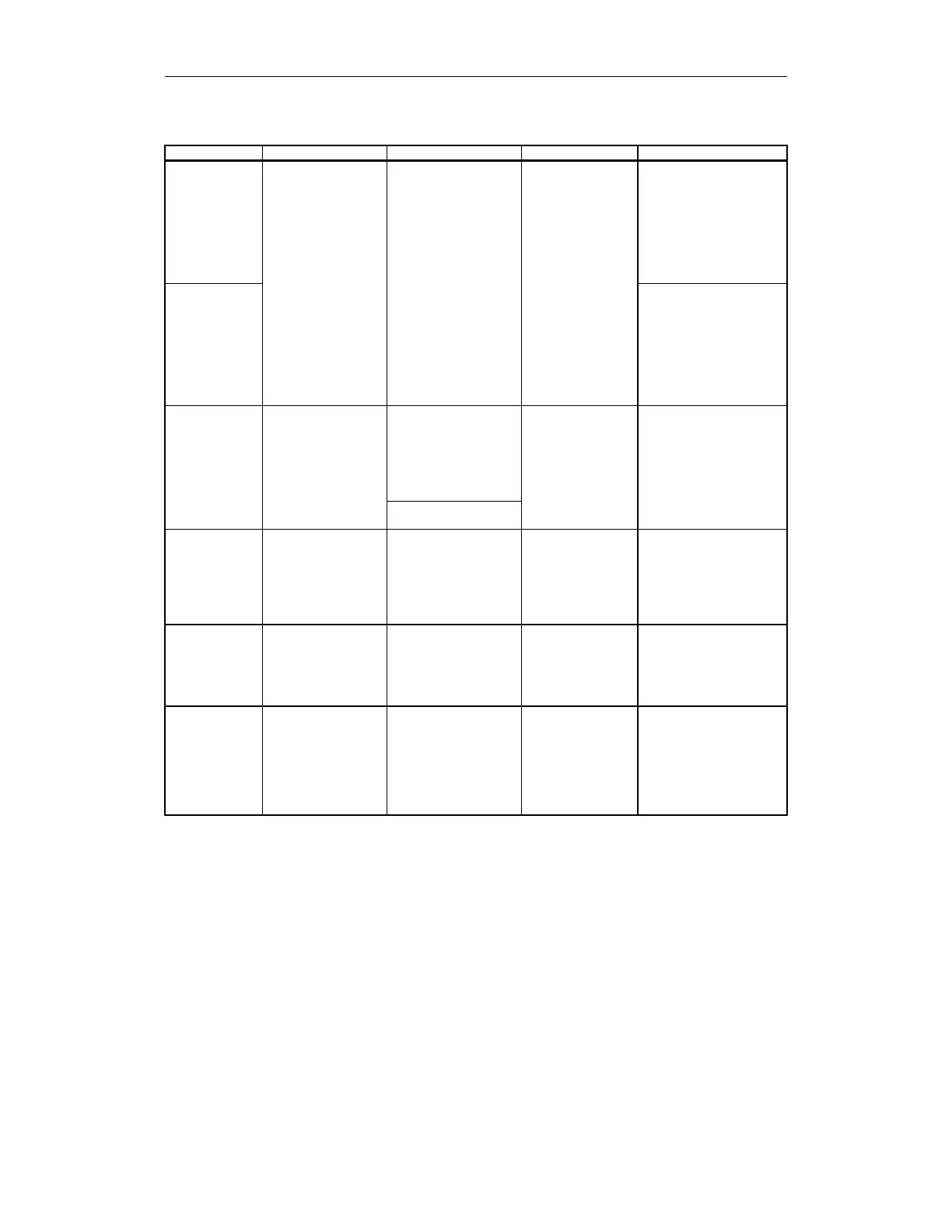

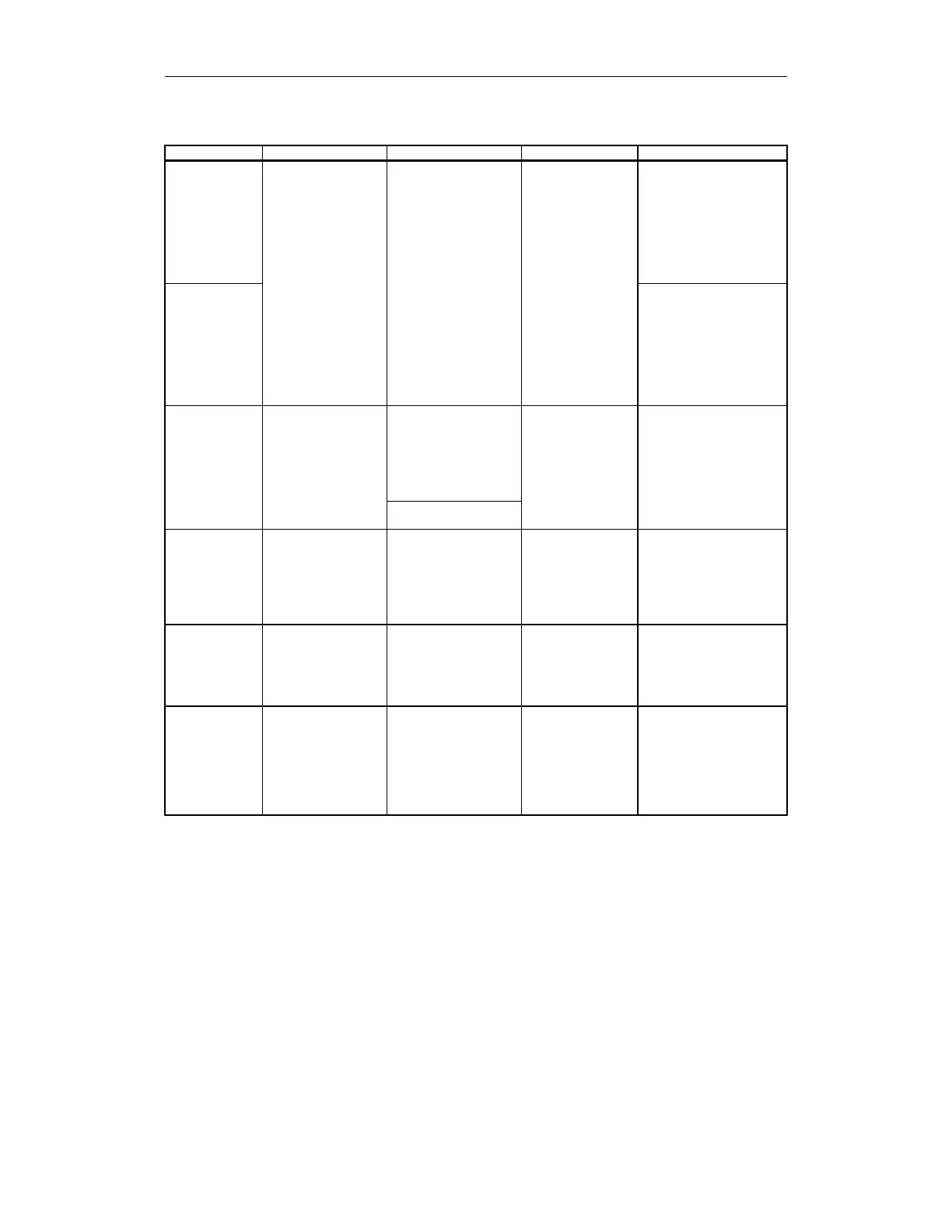

Table 2-12 Error analysis in test mode

Assumed error Error causes Error control MDIR, Appendix

1)

Comments

Spindle speed

too high

Defect in the drive or

control system,

encoder fault in 2-

encoder operation,

operator error etc.

Safe limitation of speed

or axis velocity with SG;

configurable stop

functions according to

Cat. 2

Chapter 1.2.4

Chapter 1.2.7

Chapter 1.3.6

According to currently

applicable standards

(TC143), the SG function

– depending on the

technology – is only

permissible in combination

with agreement, jog mode,

start button and

Emergency Stop

Axis speed too

high

or similar According to currently

applicable standards

(TC143), the function –

depending on the

technology – is only

permissible in combination

with JOG mode, start

button and Emergency

Stop

Axis or spindle

has inadmissibly

moved away

from standstill

position

Defect in the drive or

control system,

operator error etc.,

part program error

or similar

Safe standstill

monitoring for position

control with SBH;

configurable stop

function acc. To Cat.

0/1

Chapter 1.2.6

Chapter 1.2.7

Chapter 1.3.6

Chapter 1.4.2

Chapter 1.4.3

No wear, safe

disconnection of energy

feed to drive to allow

manual intervention in

danger zone; function

does not replace machine

main switch

Safe standstill with SH,

Stop function, Cat. 0

with respect to electrical

isolation

Axes have

inadmissibly

exited operating

range

Defect in the drive or

control system,

operator error etc.,

part program error

or similar

"Safe software limit

switches" SE;

configurable stop

functions according to

Cat. 2

Chapter 1.2.4

Chapter 1.2.7

Chapter 1.3.7

Chapter 1.3.8

Wear-free safe cams,

are essentially used for

machinery protection,

can also be used to

restrict working zones in

conjunction with personnel

protection

Response of the

machine control

to incorrect

position signal

Defect in the control

operator error,

part program error

or similar

"Safe software cams"

SN;

safe signal and position

data output

Chapter 1.2.4

Chapter 1.2.7

Chapter 1.3.8

Chapter 1.4.2

Chapter 1.4.3

Wear-free "safe software

cams"

used to safely detect the

position of axes.

Can be used to demarcate

physical areas

Error relating to

the input/output

of process data

Defective cable,

incorrect information

or similar

Two-channel

input/output of safety-

relevant signals

(SGE/SGA), crosswise

data comparison;

initiation of stop

functions according to

Cat. 1

Chapter 1.2.5

Chapter 1.3.8

Chapter 1.4.2

Chapter 1.4.3

External two-channel

inputs or further

processing required if

function is intended to

protect operating

personnel

1)

refer to: Appendix, References General /1/

Loading...

Loading...