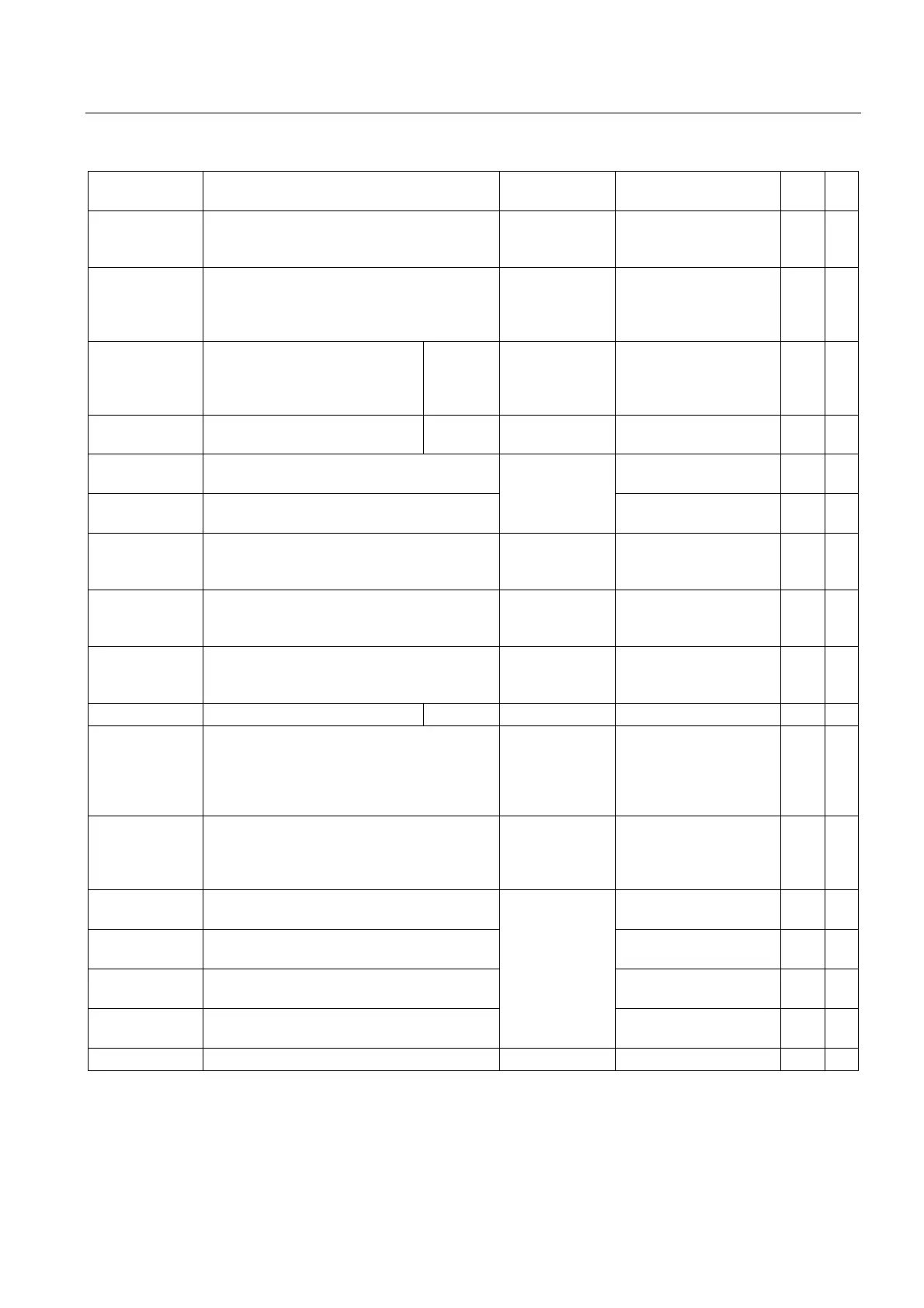

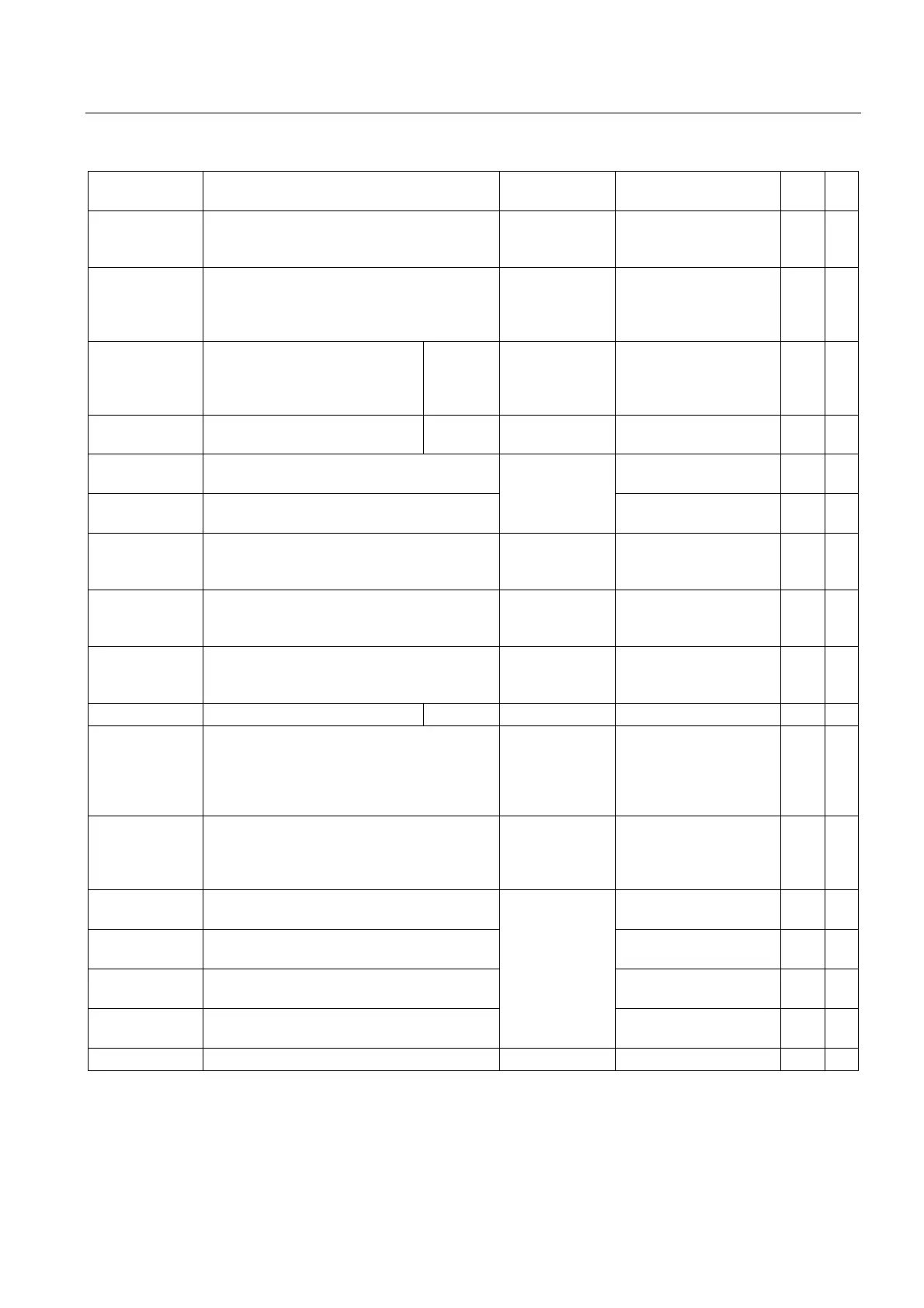

Tables

12.1 List of statements

Fundamentals

Programming Manual, 10.2004 Edition, 6FC5 298-7AB00-0BP1

12-19

STARTFIFO

1

Execute; simultaneously fill preprocessing

memory

m 4

STOPFIFO Stop machining; fill preprocessing memory

until STARTFIFO is detected, FIFO full or end

of program

m 4

SUPA Suppression of current zero offset, including

programmed offsets, system frames,

handwheel offsets (DRF), external zero offset

and overlaid motion

s 9

T Call tool

(only change if specified in

machine data; otherwise M6

command necessary)

1, ...,

32 000

Call via

T No.: or via tool

identifier:

e.g., T3 or T=3

e.g., T="DRILL"

TCARR Request toolholder (number "m") Integer m=0: deselect

active toolholder

TCARR=1

TCOABS

1

Determine tool length components from the

current tool orientation

m 42

TCOFR Determine tool length components from the

orientation of the active frame

Necessary after

reset, e.g.,

through manual

setting

m 42

TCOFRX Determine tool orientation of an active frame

on selection of tool, tool points in X direction

Tool

perpendicular to

inclined surface

m 42

TCOFRY Determine tool orientation of an active frame

on selection of tool, tool points in Y direction

Tool

perpendicular to

inclined surface

m 42

TCOFRZ Determine tool orientation of an active frame

on selection of tool, tool points in Z direction

Tool

perpendicular to

inclined surface

m 42

TILT

5

Tilt angle Real m

TMOF Deselect tool monitoring T no. is only

necessary if the

tool with this

number is not

active.

TMOF (T no.)

TMON Activate tool monitoring T No. = 0:

Deactivate

monitoring for all

tools

TMON (T no.)

TOFRAME Set current programmable frame to tool

coordinate system

m 53

TOFRAMEX X axis parallel to tool direction, secondary

axis Y, Z

m 53

TOFRAMEY Y axis parallel to tool direction, secondary

axis Z, X

m 53

TOFRAMEZ Z axis parallel to tool direction, secondary

axis X, Y

Frame rotation

in tool direction

m 53

TOROTOF Frame rotations in tool direction OFF m 53

Loading...

Loading...