Detailed Description

2.4 Tool: Tool radius compensation 2D (TRC)

Tool Compensation (W1)

2-58 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

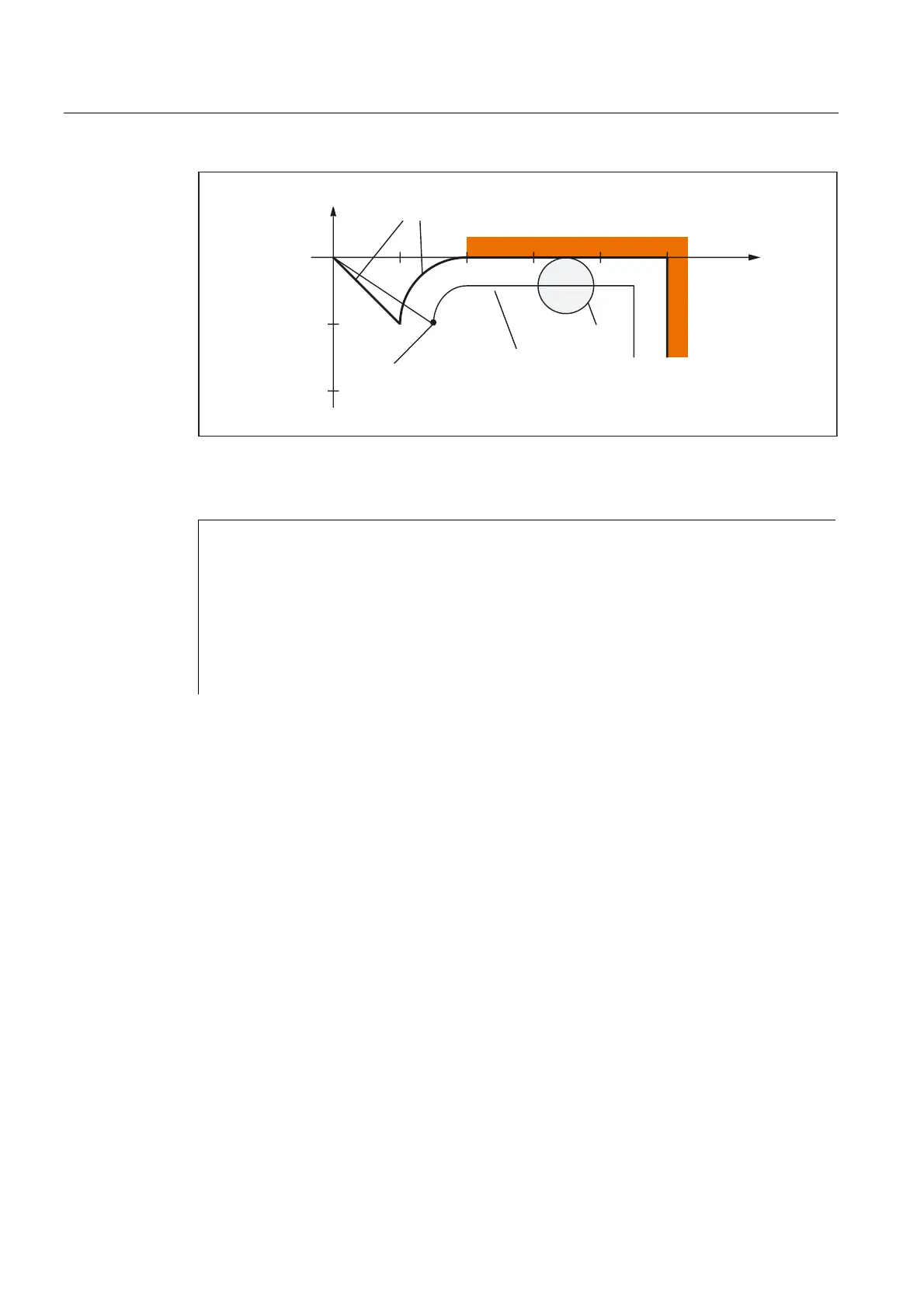

6$5FRQWRXU

7RRO

,QIHHG

PRYHPHQWLQ=

7RROFHQWHUSDWK

;

<

Fig. 2-24 Contour example 1

Part program:

$TC_DP1[1,1]=120 ; Tool definition T1/D1

$TC_DP6 [1,1] = 10 ; Radius

N10 G0 X0 Y0 Z30

N20 G247 G341 G42 NORM D1 T1 Z0 FAD=1000 F=2000 DISCL=5 DISR=10

N30 X40

N40 X100

N50 Y-30

...

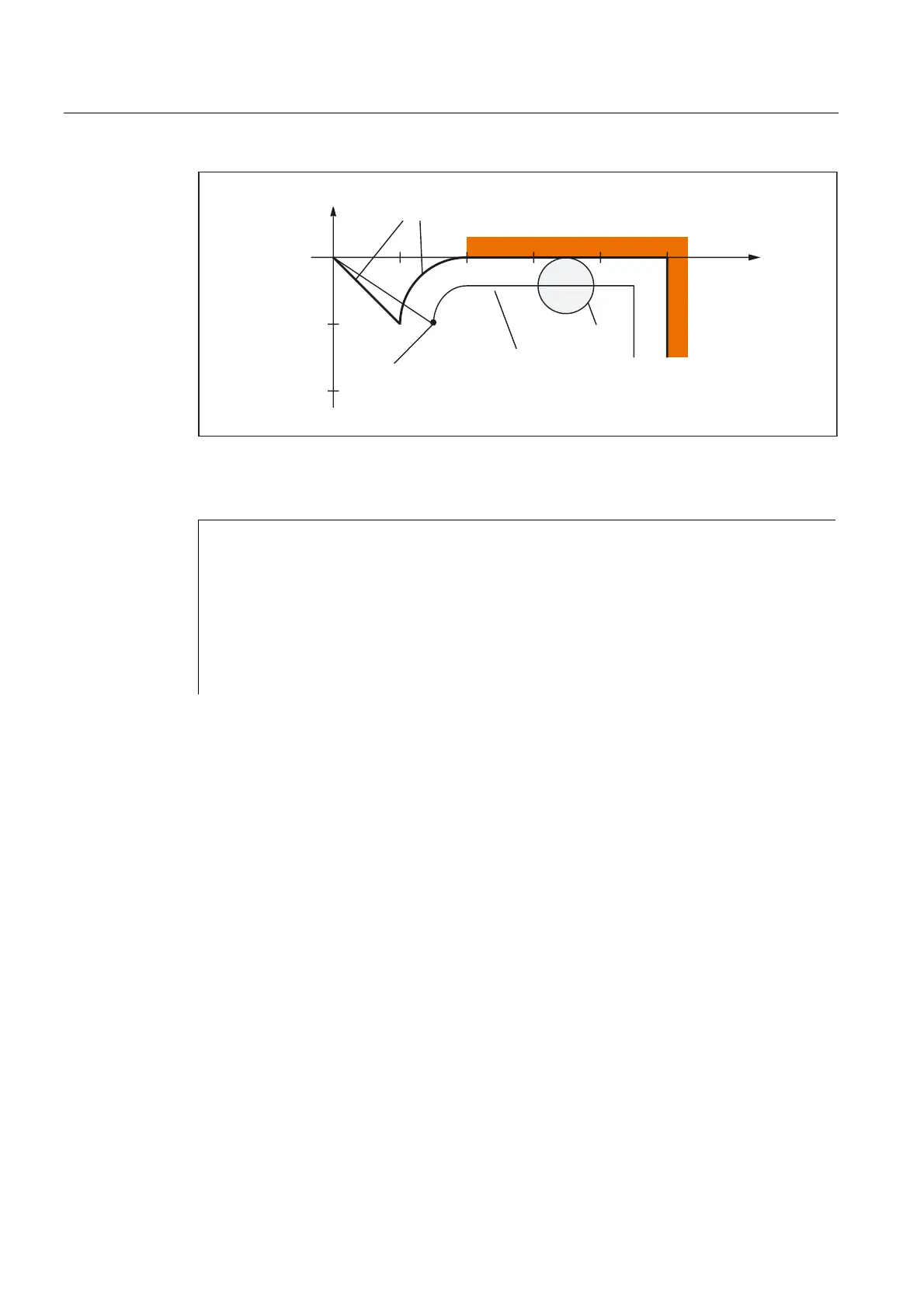

Example 2

The following conditions must be true for approach:

• Smooth approach is activated in block N20

• Approach movement performed with quadrant (G247)

• Approach direction not programmed, G140 is valid, i.e., because TRC is active (G41), the

contour is approached from the left

• Contour compensation OFFN=5 (N10)

• Current tool radius=10, and so the effective compensation radius for TRC=15; the radius

of the SAR contour is thus equal to 25, with the result that the radius of the tool center

path is equal to DISR=10

• The end point of the circle is obtained from N30, since only the Z position is programmed

in N20

• Infeed movement

– From Z20 to Z7 (DISCL=AC(7)) with rapid traverse

– Then on to Z0 with FAD=200

– Approach circle in X/Y plane and following blocks with F1500. (For this velocity to be

active in the following blocks, the active G code G0 must be overwritten in N30 with G1.

Otherwise, the contour would continue to be machined with G0.)

Loading...

Loading...