Detailed Description

2.5 Toolholder with orientation capability

Tool Compensation (W1)

2-90 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

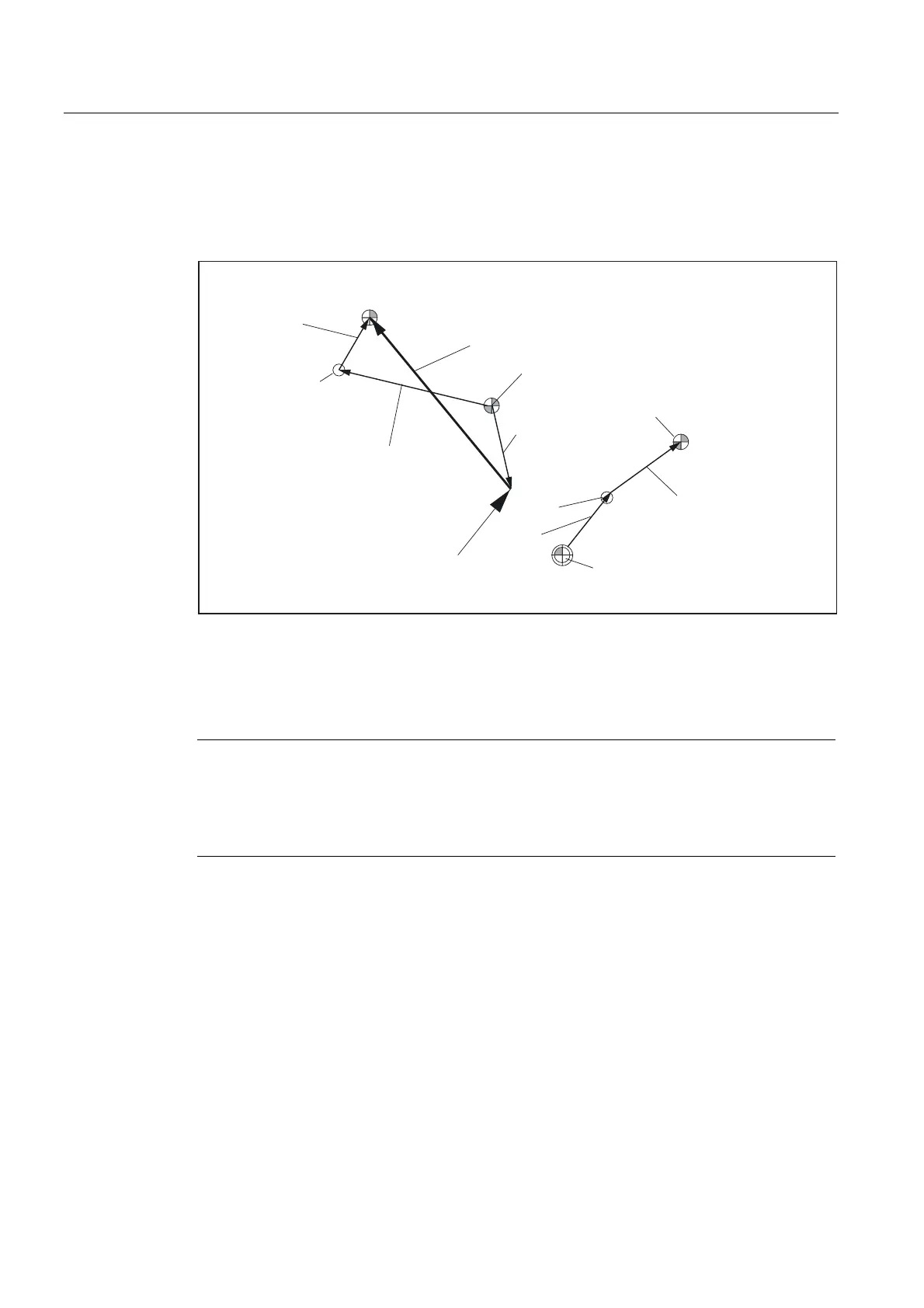

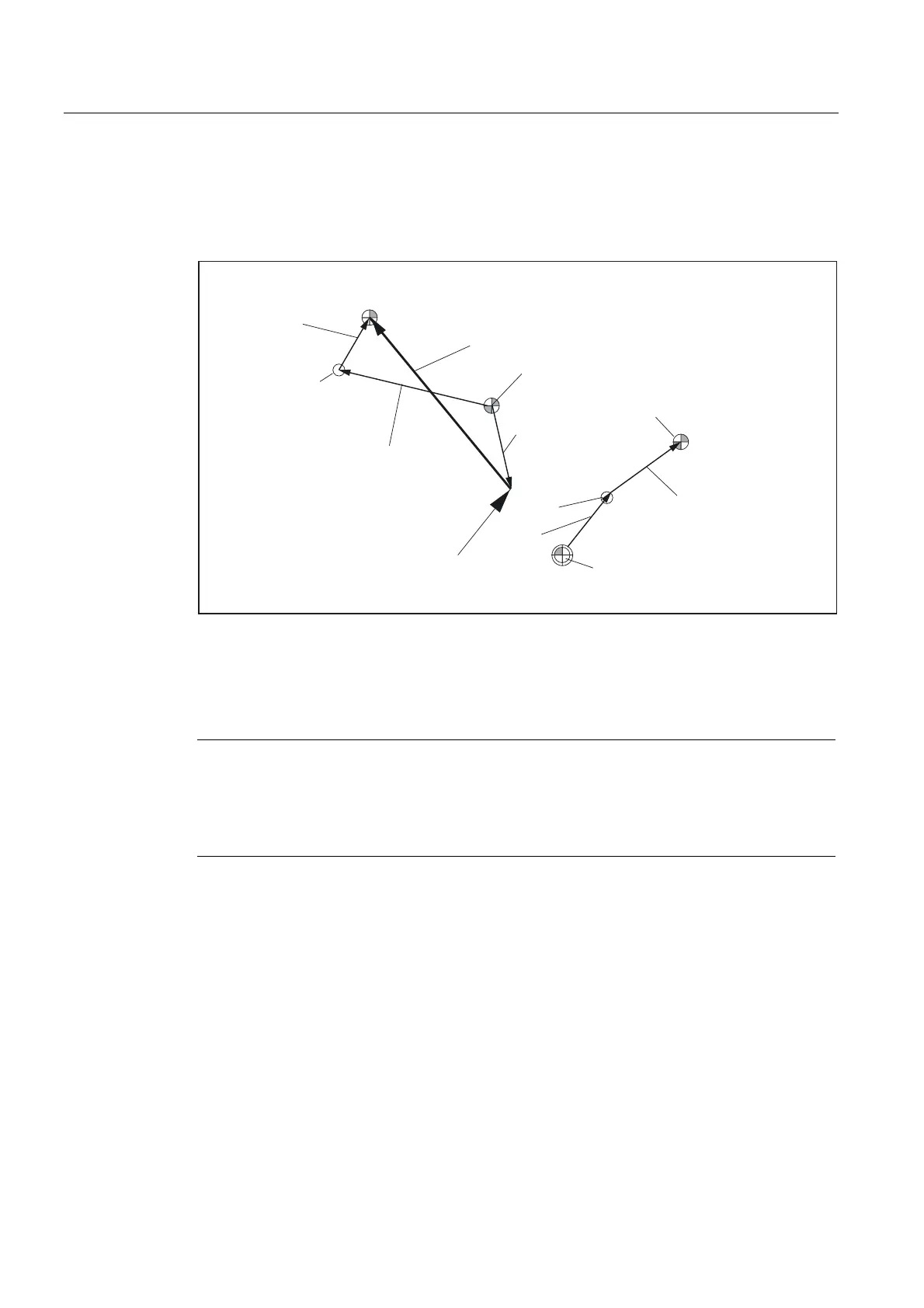

The kinematic of the rotary tool is described with the first rotary axis (v

1

) and the two vectors

l

1

and l

2

, that of the rotary table with the second rotary axis (v

2

) and the two vectors l

3

and l

4

.

The two kinematic chain components for machines with rotary tool and rotary workpiece are

shown in the figure below.

7RROOHQJWK

ZHDU

WRROEDVHGLPHQVLRQ

5HVXOWLQJWRROOHQJWKFRPSHQVDWLRQ

5HIHUHQFHSRLQWRIWKH

WRROKROGHU

7RRORULHQWDWLRQ

5HIHUHQFHSRLQWRI

WKHWRRO

0DFKLQHUHIHUHQFHSRLQW

5HIHUHQFHSRLQWRI

WKHWRROWDEOH

O

O

Y

˞

O

O

Y

˞

Fig. 2-44 Kinematic sequence with extended kinematics

The following kinematic type is defined for machines with a rotary tool and rotary workpiece:

$TC_CARR23 using letter M (extended kinematics)

Note

On machines with extended kinematics it is generally useful, as with machines where only

the table can be rotated, for the machine reference point and the reference point of the table

to be identical. The (open) chain component to describe the table (see figure) is then closed.

In this special case, the following formula applies: l

3

= - l

4

Rotary tool types T and M

For machine kinematics with a rotary tool (types T and M), the toolholder component with

orientation capability, which describes the tool or head component (as opposed to the table

component), acts, in conjunction with the active tool, as a new overall tool.

Loading...

Loading...