Detailed Description

2.5 Toolholder with orientation capability

Tool Compensation (W1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-93

5HVXOWLQJWRROOHQJWKFRPSHQVDWLRQ

/HQJWKZHDU

7RROEDVHGLPHQVLRQ

7RROFDUULHUUHIHUHQFHSRLQW

$[LV

$[LV

7RROUHIHUHQFHSRLQW

[

]

\

PP

O

O

Y

Y

O

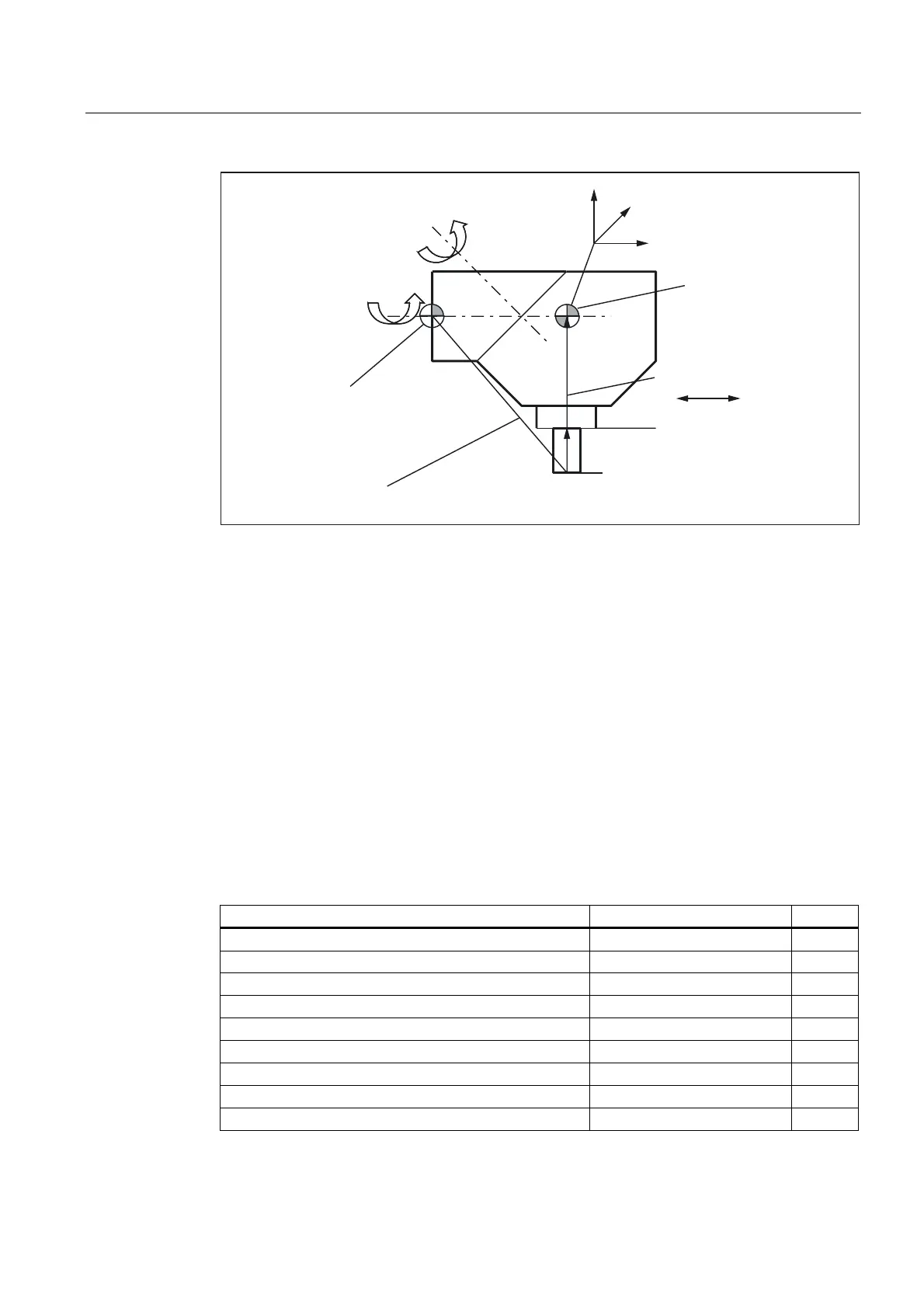

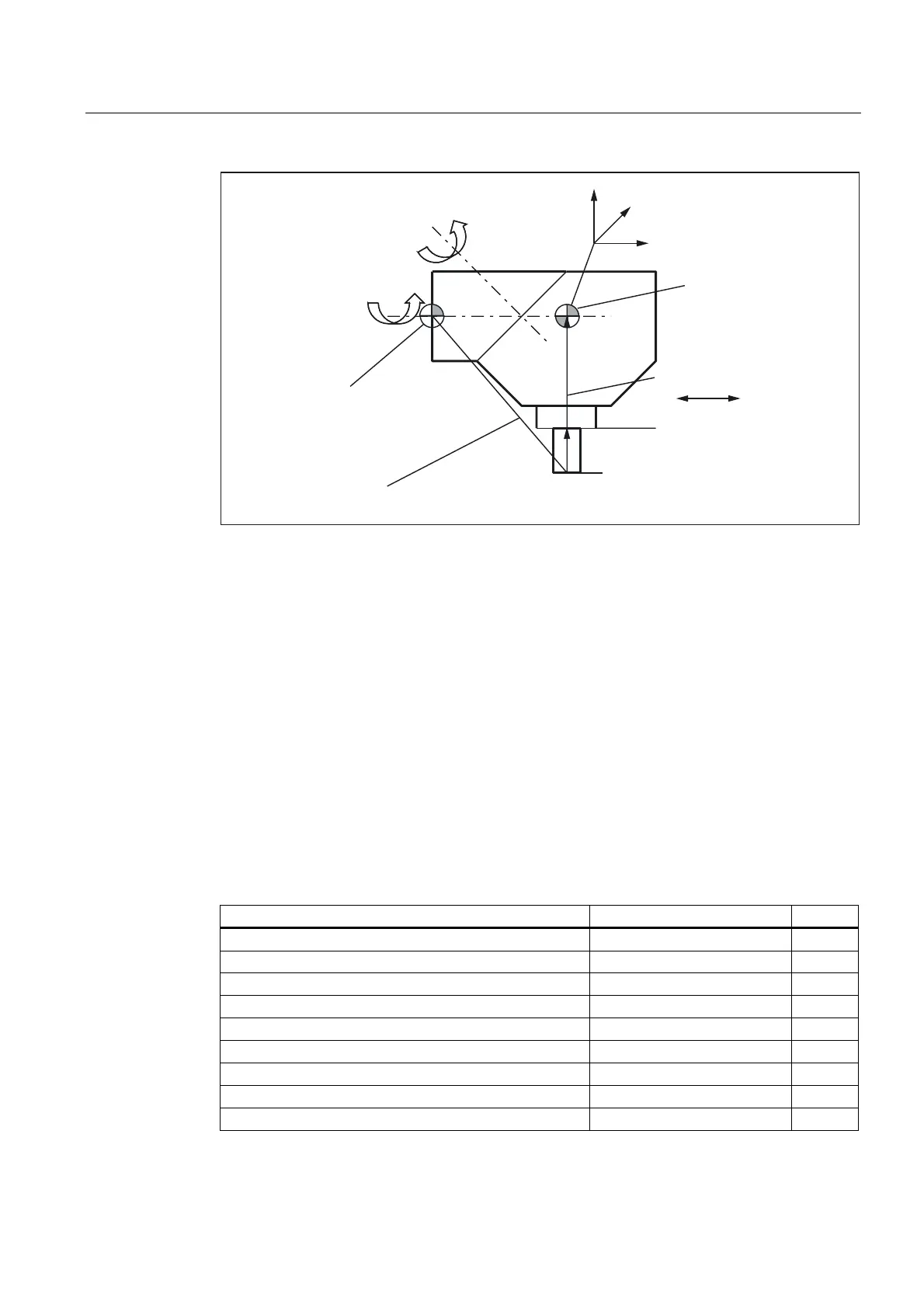

Fig. 2-45 Assignment of the toolholder data

Suitable assumptions were made for the following values in the data block:

• The two rotary axes intersect at one point.

All components of l

2

are therefore zero.

• The first rotary axis lies in the x/z plane, the second rotary axis is parallel to the x axis.

These conditions define the directions of v

1

and v

2

(the lengths are irrelevant, provided

that they are not equal to zero).

• The reference point of the toolholder lies 200 mm in the negative x direction viewed from

the intersection of the two rotary axes.

This condition defines l

1

.

Specify associated data block values

The following associated data block values are specified for the toolholder shown on a

machine with rotary toolholder:

Description NCK variables Value

x component of offset vector l

1

$TC_CARR1 - 200

y component of offset vector l

1

$TC_CARR2 0

z component of offset vector l

1

$TC_CARR3 0

x component of offset vector l

2

$TC_CARR4 0

y component of offset vector l

2

$TC_CARR5 0

z component of offset vector l

2

$TC_CARR6 0

x component of rotary axis v

1

$TC_CARR7 1

y component of rotary axis v

1

$TC_CARR8 0

z component of rotary axis v

1

$TC_CARR9 0

Loading...

Loading...