Detailed Description

2.5 Toolholder with orientation capability

Tool Compensation (W1)

2-94 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

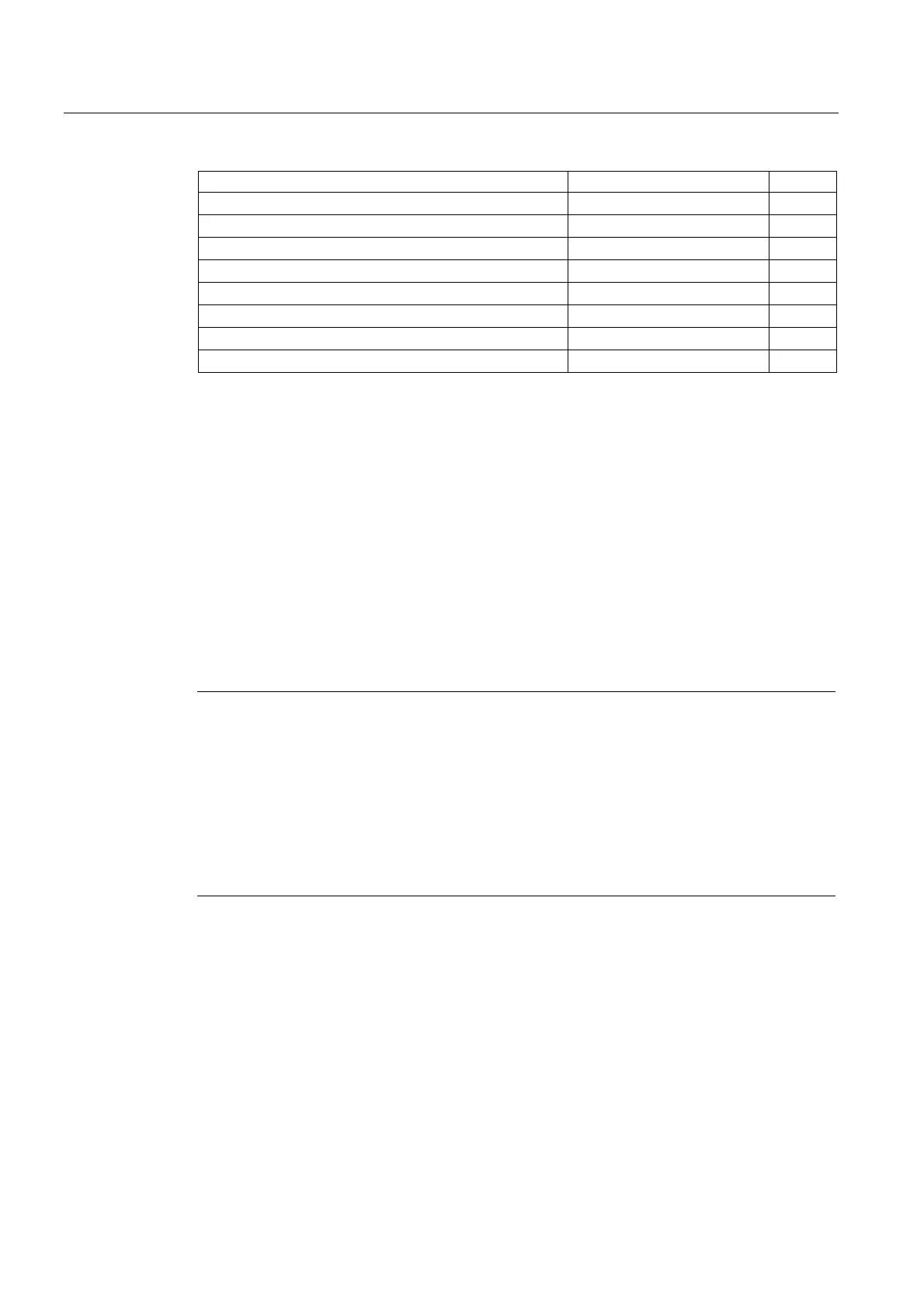

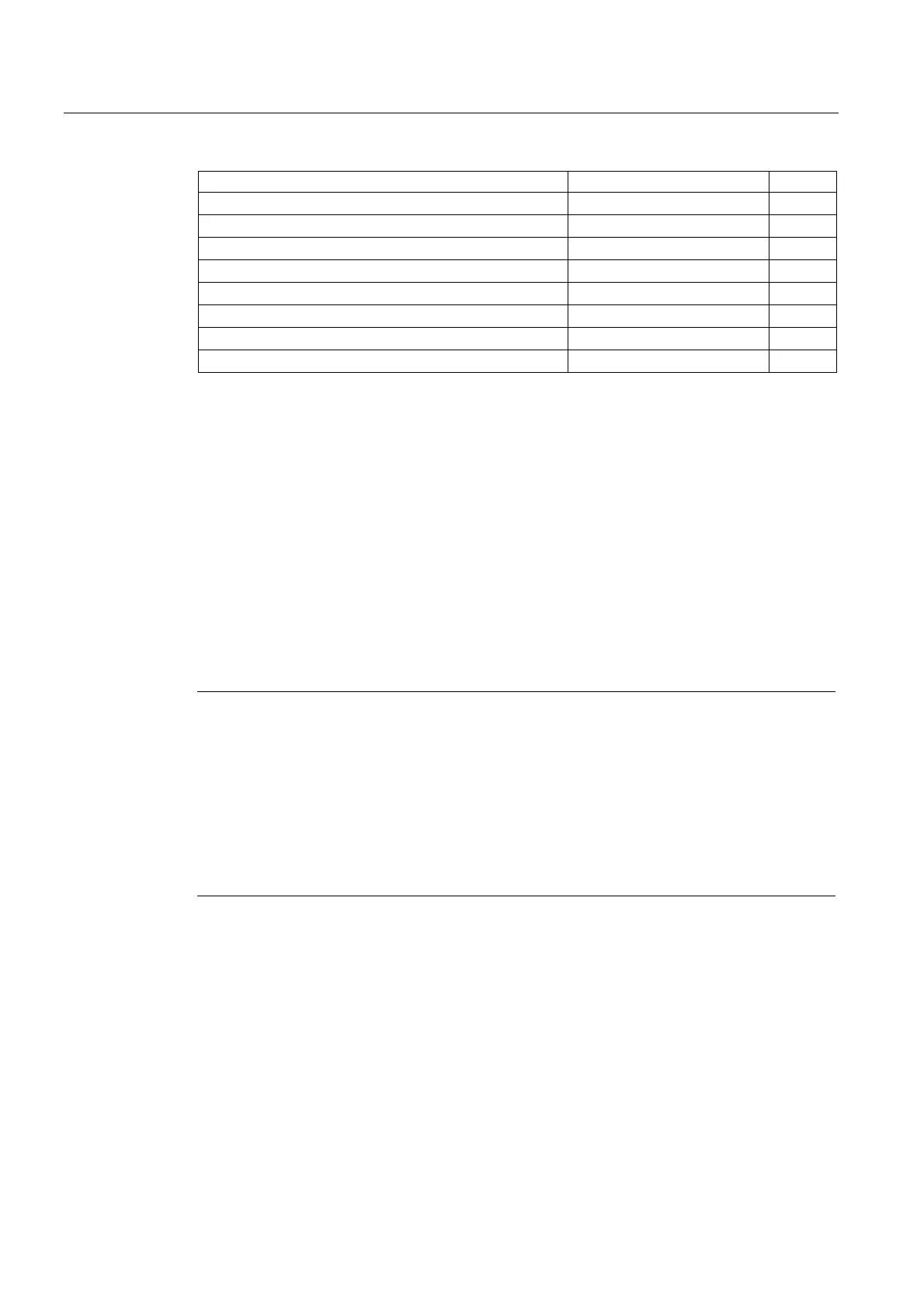

Description NCK variables Value

x component of rotary axis v

2

$TC_CARR10 -1

y component of rotary axis v

2

$TC_CARR11 0

z component of rotary axis v

2

$TC_CARR12 1

Angle of rotation α1(in degrees) $TC_CARR13 0

Angle of rotation α2(in degrees) $TC_CARR14 0

x component of offset vector l

3

$TC_CARR15 -100

y component of offset vector l

3

$TC_CARR16 0

z component of offset vector l

3

$TC_CARR17 0

Explanation

The toolholder kinematic chosen in the example is such that the two rotary axes form an

angle of 45 degrees, which means that the orientation cannot take just any value. In

concrete terms, this example does not permit the display of orientations with negative X

components.

x component of the tool base dimension: 0

y component of the tool base dimension: 0

z component of the tool base dimension: 250

Note

The required data cannot be determined unequivocally from the geometry of the toolholder,

i.e., the user is free to a certain extent to decide the data to be stored. Thus, for the example,

it is possible to specify only one z component for the tool base dimension up to the second

axis. In this case, l

2

would no longer be zero, but would contain the components of the

distance between this point on the second axis and a further point on the first axis. The point

on the first axis can also be selected freely. Depending on the point selected, l

1

must be

selected such that the reference point (which can also be selected freely) is reached.

In general: vector components that are not changed by rotation of an axis can be distributed

over any vectors "before" and "after" rotation.

Loading...

Loading...