Detailed Description

2.7 Program operation mode

Mode Group, Channel, Program Operation, Reset Response (K1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-105

Interrupt signals

A total of 8 interrupt signals are available.

All inputs can be controlled from the PLC.

In addition, the first four interrupt signals are controlled via the 4 rapid NC inputs on the

NCU module (X121).

The signal state of the rapid NC inputs can be read out via the PLC interface (DB10).

Transmission of the rapid NC input signals to the interrupt signals can be disabled via the

PLC interface (DB10).

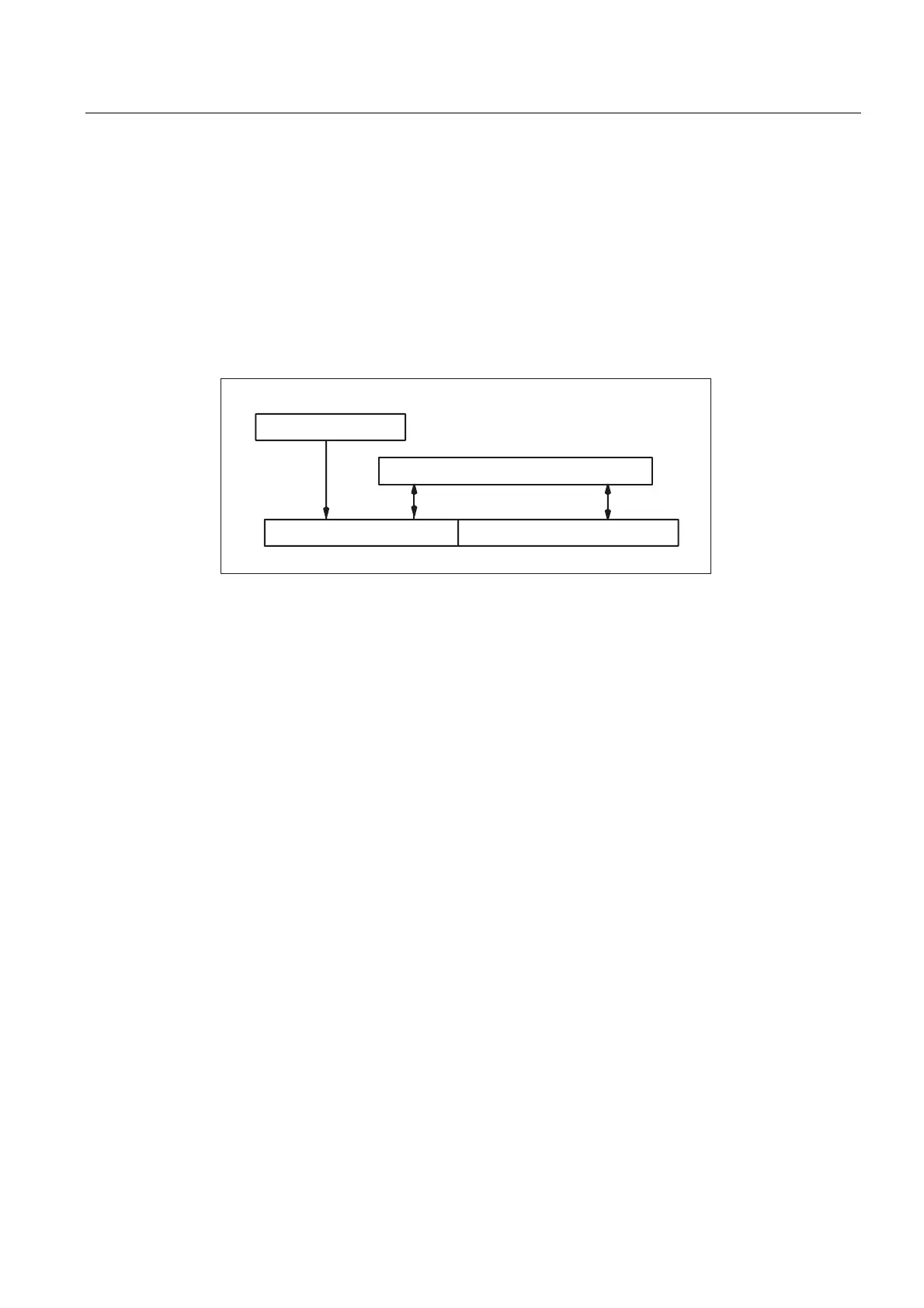

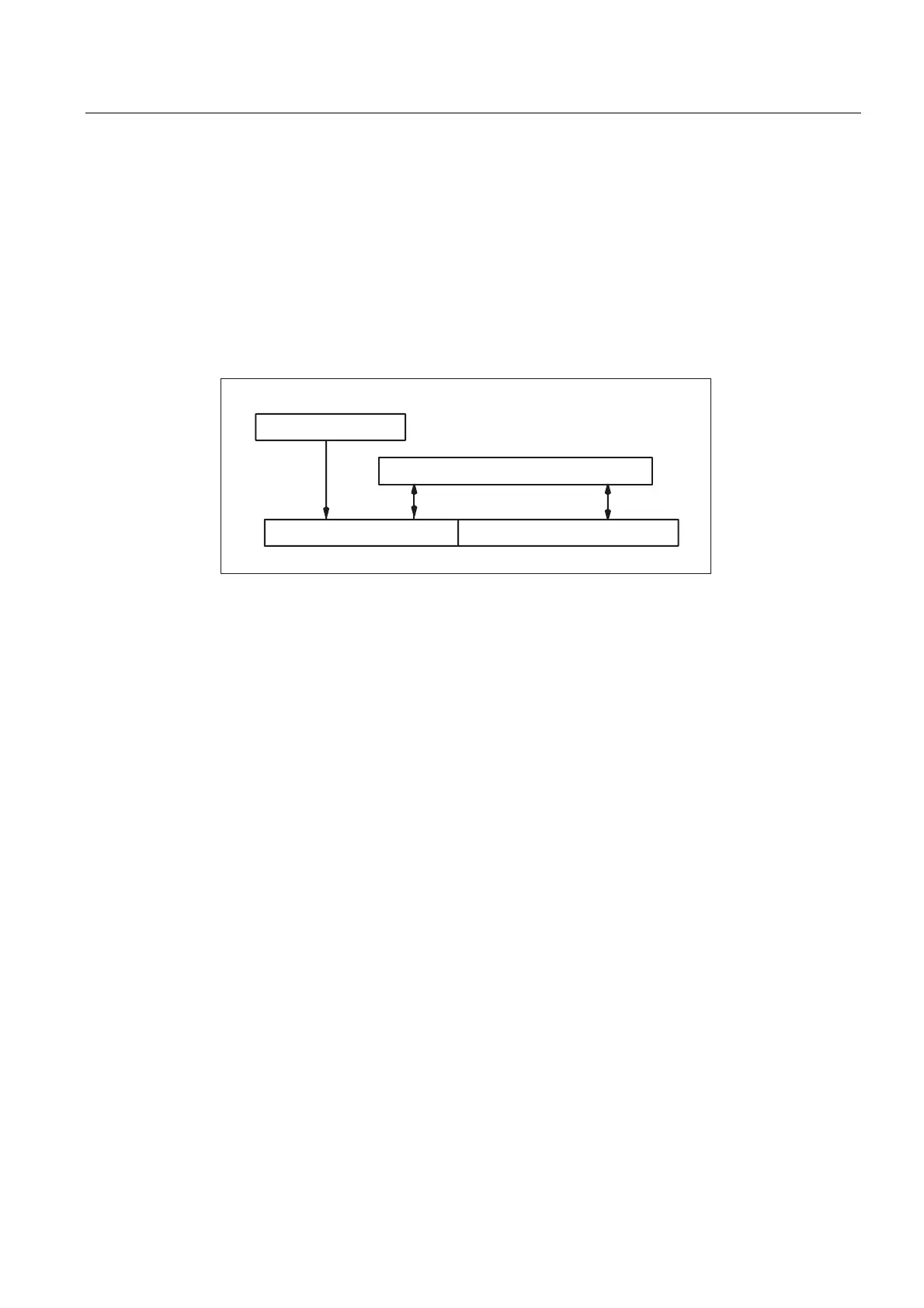

PLC interface

4 interrupt signals

4 rapid NC inputs

4 interrupt signals

Fig. 2-12 Interrupt signals

For further information about PLC control of the rapid NC inputs (interrupt signals) see:

References: /FB2/, A4, "Digital and Analog NCK I/Os"

Activation of interrupt routine

Interrupt routines can be activated by two different methods:

• By a 0/1 transition of the interrupt signal, triggered by a 0/1 transition at the rapid

NC input

• By the call of function call ASUPST (/B1/, /P3/)

Upon activation, all machine axes are decelerated to a standstill according to the

acceleration ramp (MD32300 $MA_MAX_AX_ACCEL (axis acceleration)), and the axis

positions are stored.

Reorganization

In addition to decelerating the axes, the previously decoded calculation blocks are calculated

back to the interruption block. i.e., all the variables, frames and G codes are assigned the

value that they would have at the point of interruption if the part program had not been

previously decoded. These values are put in the buffer so that they can be called up again

when the interrupt routine is completed.

Loading...

Loading...