Fundamental Principles and System Description

Engineering Information

SINAMICS Engineering Manual – November 2015

Ó Siemens AG

146/528

1.9.4.2 Summary of bearing current types and counter-measures

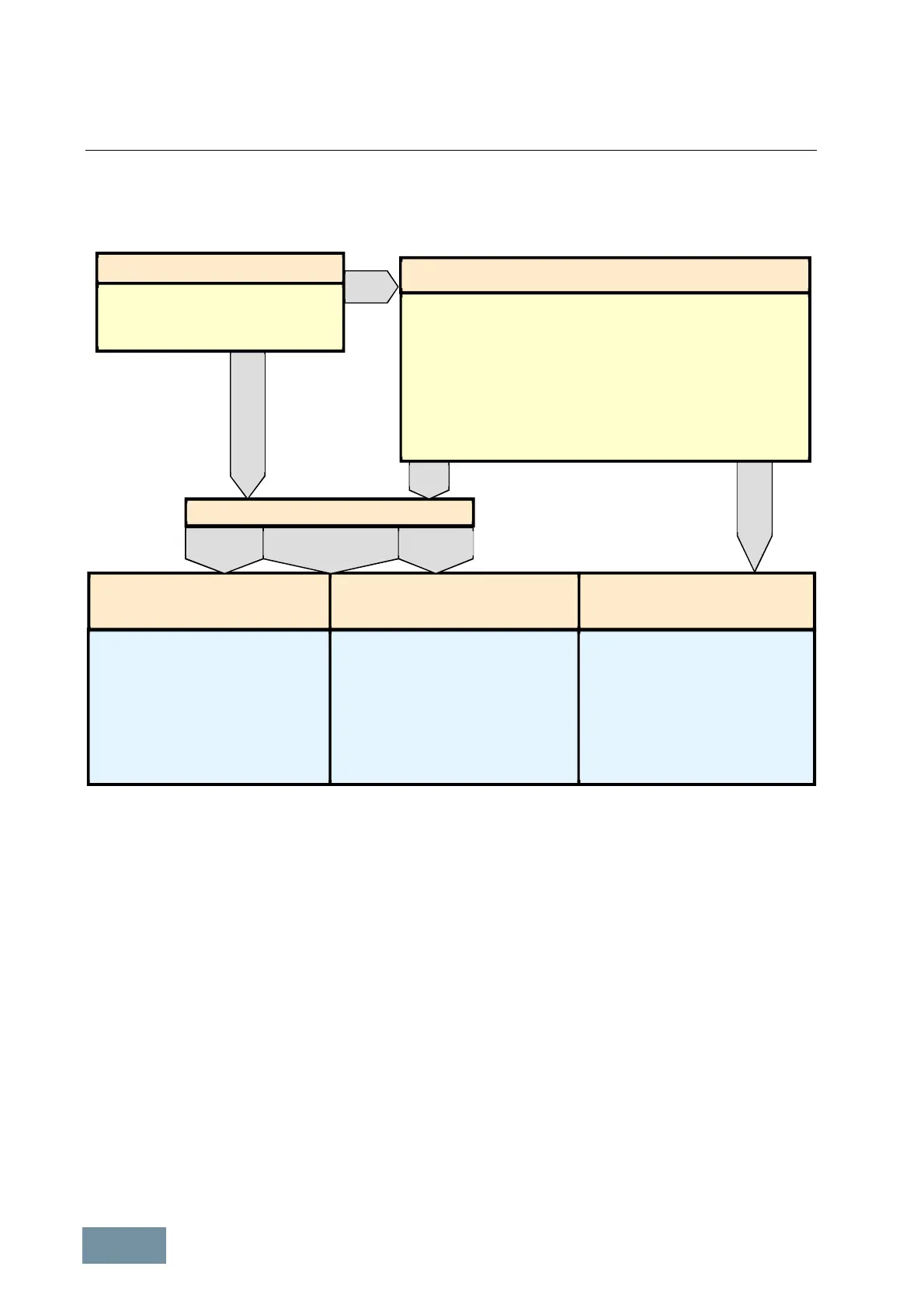

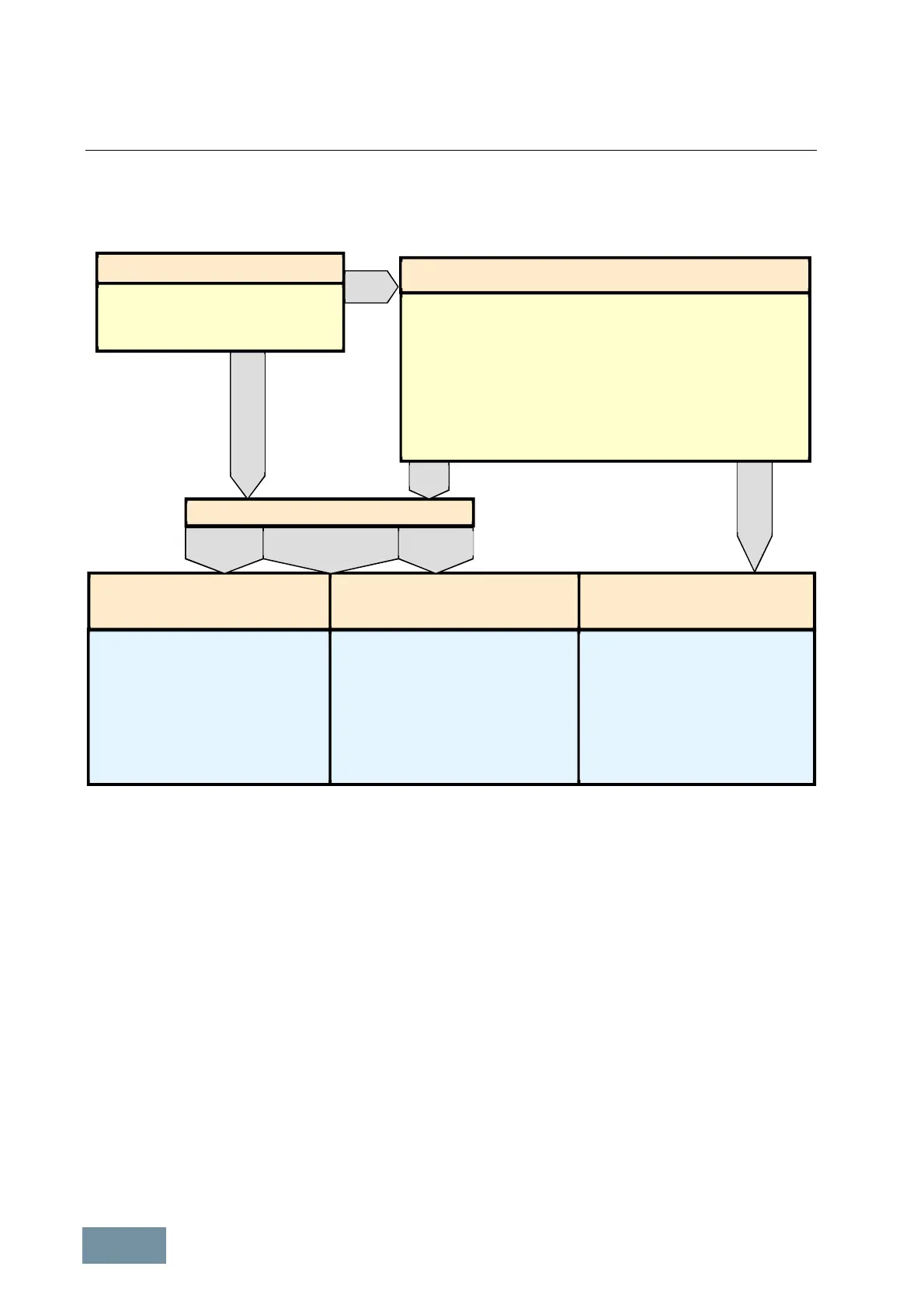

The following overview shows the different types of bearing currents depending on the shaft height and the grounding

conditions of stator and rotor.

Dominant bearing current types dependent on the shaft height and the grounding conditions of stator and rotor

If the rotor is well grounded via a conductive coupling and a well-grounded driven machine or load but the stator is

poorly grounded due to unsatisfactory installation, the rotor grounding currents become dominant which, in turn, can

quickly damage the bearings of the motor and driven machine or load. These situations must be avoided absolutely

by ensuring that the stator is properly grounded in an EMC-compliant installation and/or by means of an insulating

coupling.

If, by means of a well grounded stator with an EMC-compliant installation and/or an insolating coupling, the

occurrence of rotor shaft currents is prevented, EDM currents are dominant in smaller motors with shaft heights of up

to 100. Circular currents play a secondary role here. So the resulting bearing currents are on a low-risk level for the

bearings and no further measures usually need to be taken. As the shaft height increases, the EDM currents change

slightly, while the circular currents continually increase. From shaft heights of 225 the circular currents become

dominant and critical for the bearings. Therefore, from shaft heights of 225, the use of an isolated bearing on the

NDE of the motor is very highly recommended. This applies in particular if the motor is operated frequently or

continuously

· at low speeds below approximately 800 – 1000 rpm, or is required to operate

· at speeds that change very quickly,

because an even, stable lubricating film cannot develop in the bearing under these operating conditions.

Basically a dv/dt filter or a sinusoidal filter can also be used at the output of the converter, as alternative to an isolated

bearing in the motor.

The measures to be implemented on the motor in order to prevent bearing current damage are illustrated graphically

below.

Rotor grounding

Stator grounding

Rotor shaft currents

Counter measure:

EDM currents

Counter measure:

Circular currents

Counter measure:

no

EDM currents without superimposed

circular and rotor shaft currents have a

tolerable magnitude. Therefore, usually

no measures are required.

§ Isolated bearing on the NDE of the

motor (NDE = Non-Drive End)

or, alternatively

§ dv/dt filter or sinusoidal filter at the

output of the converter / inverter

(dv/dt phase to ground < 0.5 kV/ms)

Good rotor grounding achieved through

conductive coupling to the well-grounded

driven machine?

Good stator grounding through

• shielded, symmetrical motor cable?

and

• shield connected on both sides and with a large surface area?

and

• HF potential bonding between motor housing and driven machine?

From shaft heights of ≥ 225 also recommended:

HF potential bonding between motor terminal box and housing?

yes

• shielded, symmetrical motor cable

shield (connected on both sides)

• HF potential bonding between motor

housing and driven machine

From shaft heights ≥225 recommended

• HF potential bonding between motor

terminal box and motor housing

Loading...

Loading...