SINAMICS S150

Engineering Information

SINAMICS Engineering Manual – November 2015

Ó Siemens AG

487/528

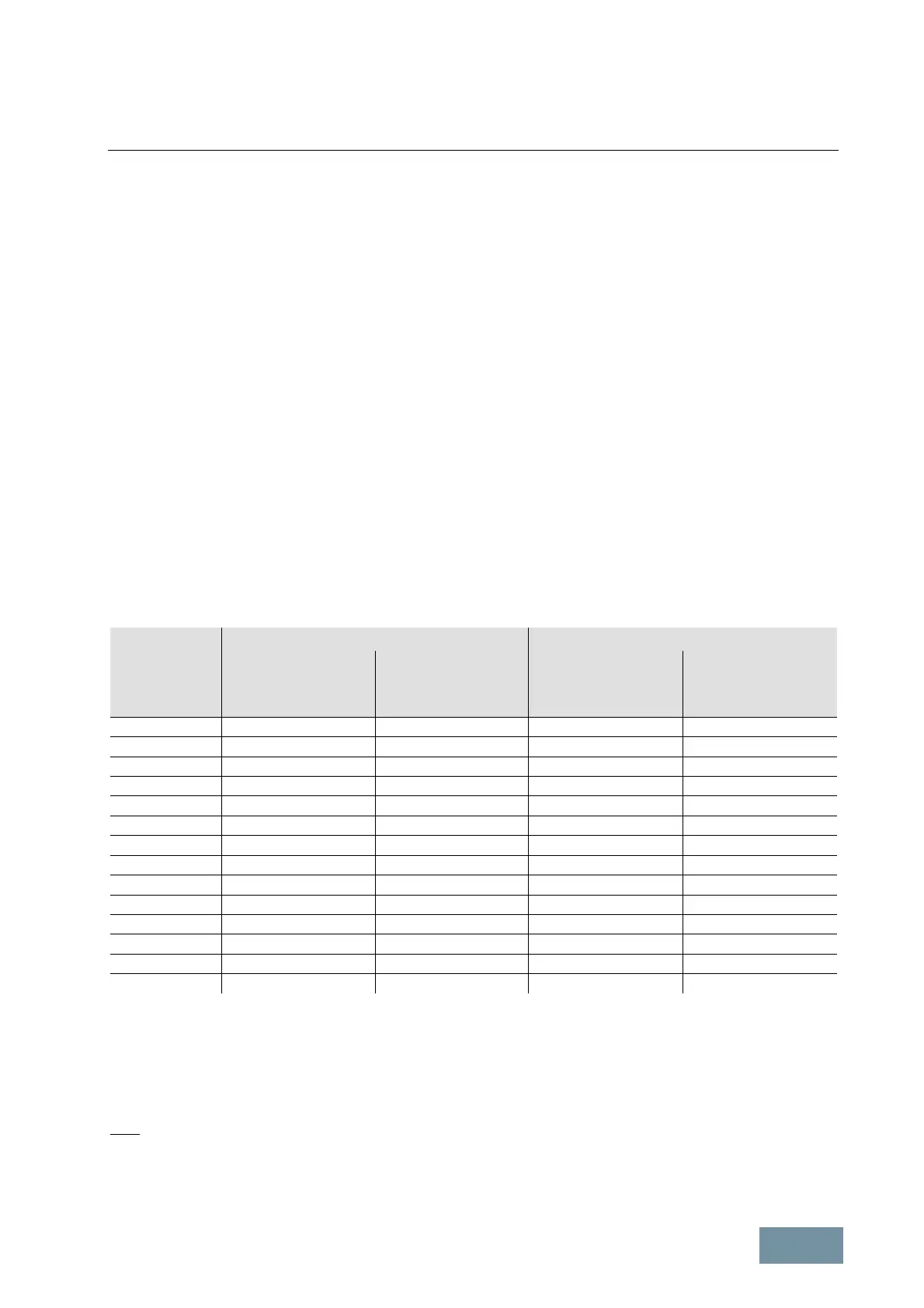

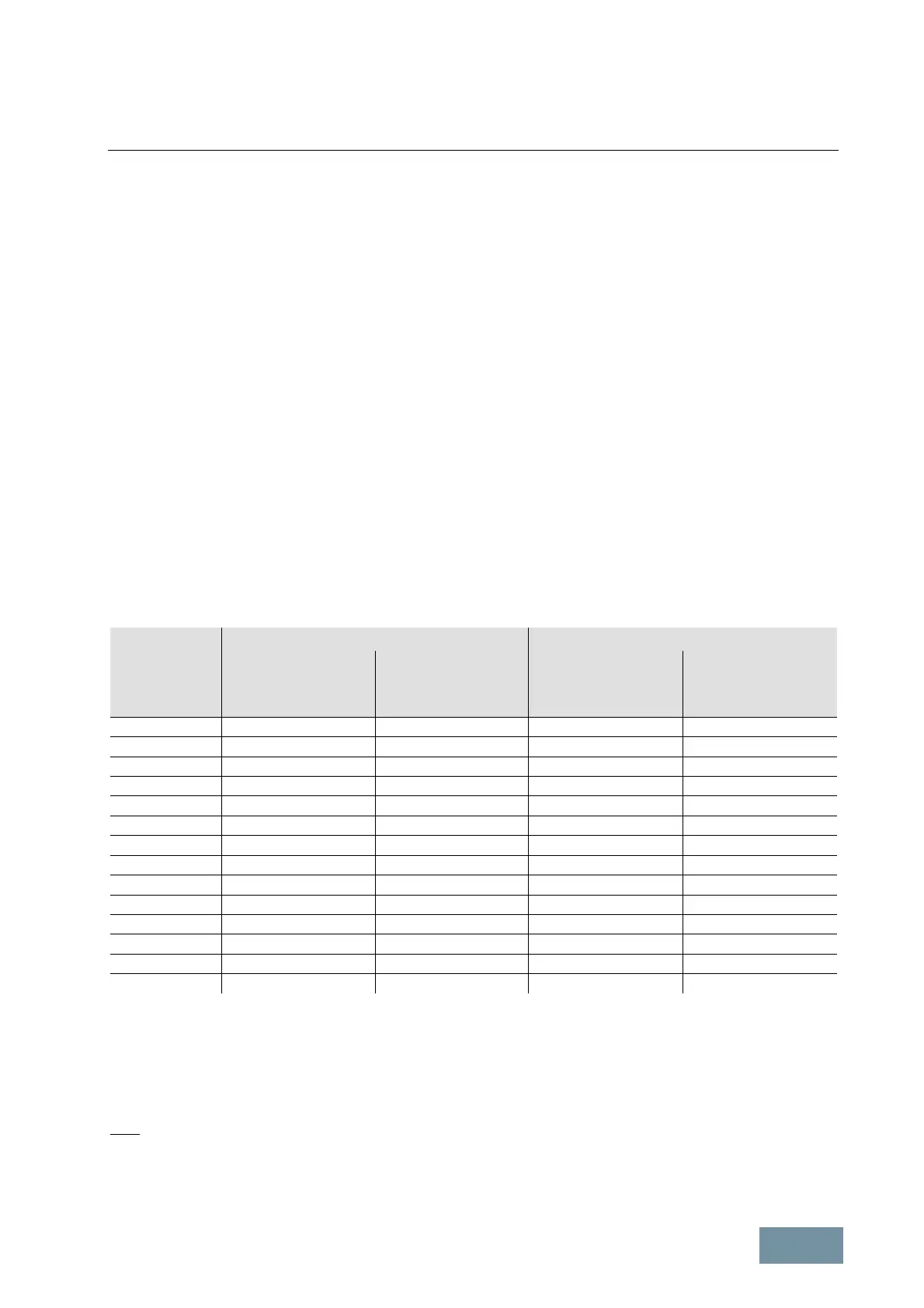

8.4.2 Required cable cross-sections for line and motor connections

Generally speaking, unshielded cables can generally be used to make the line connection. 3-wire or 4-wire three-

phase cables should be used wherever possible. By contrast, it is always advisable to use shielded cables between

the converter and motor and, in the case of drives in the higher output power range, symmetrical 3-wire, three-phase

cables, and to connect several cables of this type in parallel where necessary. There are basically two reasons for

this recommendation:

This is the only way in which the high IP55 degree of protection can be achieved for the motor terminal box without

problems because the cables enter the terminal box via glands and the number of possible glands is limited by the

geometry of the terminal box. Therefore single cables are less suitable.

With symmetrical, 3-wire, three-phase cables, the summed ampere-turns over the cable outer diameter are equal to

zero and they can be routed in conductive, metal cable ducts or racks without any significant currents (ground current

or leakage current) being induced in these conductive, metal connections. The danger of induced leakage currents

and thus of increased cable-shield losses increases with single-wire cables.

The required cable cross-section depends on the amperage which flows through the cable. The permissible current

loading of cables is defined, for example, in IEC 60364-5-52. It depends on ambient conditions such as the

temperature, but also on the routing method. An important factor to consider is whether cables are routed singly and

are therefore relatively well ventilated, or whether groups of cables are routed together. In the latter instance, the

cables are much less well ventilated and might therefore heat one another to a greater degree. For the relevant

correction factors applicable to these boundary conditions, please refer to IEC 60364-5-52. The table below provides

a guide to the recommended cross-sections (based on IEC 60364-5-52) for PVC-insulated, 3-wire copper and

aluminum cables, a permissible conductor temperature of 70°C (e.g. Protodur NYY or NYCWY) and an ambient

temperature of 40°C.

Cross-section

of 3-wire cable

[mm

2

]

Copper cable Aluminum cable

Single routing

[A]

Groups of cables

routed in parallel

1)

[A]

Single routing

A]

Groups of cables

routed in parallel

1)

[A]

3 x 2.5 22 17 17 13

3 x 4.0 30 23 23 18

3 x 6.0 37 29 29 22

3 x 10 52 41 40 31

3 x 16 70 54 53 41

3 x 25 88 69 68 53

3 x 35 110 86 84 65

3 x 50 133 104 102 79

3 x 70 171 133 131 102

3 x 95 207 162 159 124

3 x 120 240 187 184 144

3 x 150 278 216 213 166

3 x 185 317 247 244 190

3 x 240 374 292 287 224

1)

Maximum 9 cables routed horizontally in direct contact with one another on a cable rack

Current-carrying capacity of PVC-insulated, 3-wire copper and aluminum cables with a maximum permissible conductor

temperature of 70°C at an ambient temperature of 40°C according to IEC 60364-5-52

With higher amperages, cables must be connected in parallel.

Note:

The recommendations for the North American market in AWG or MCM must be taken from the appropriate NEC

(National Electrical Code) / CEC (Canadian Electrical Code) standards.

Loading...

Loading...